86 MAINTENANCE OF THE LOADER

MAINTENANCE OF THE LOADER

To avoid personal injury:

A Be sure to check and service the tractor on a

flat place with the bucket on the ground, engine

shut off, the key removed and the parking

brake on.

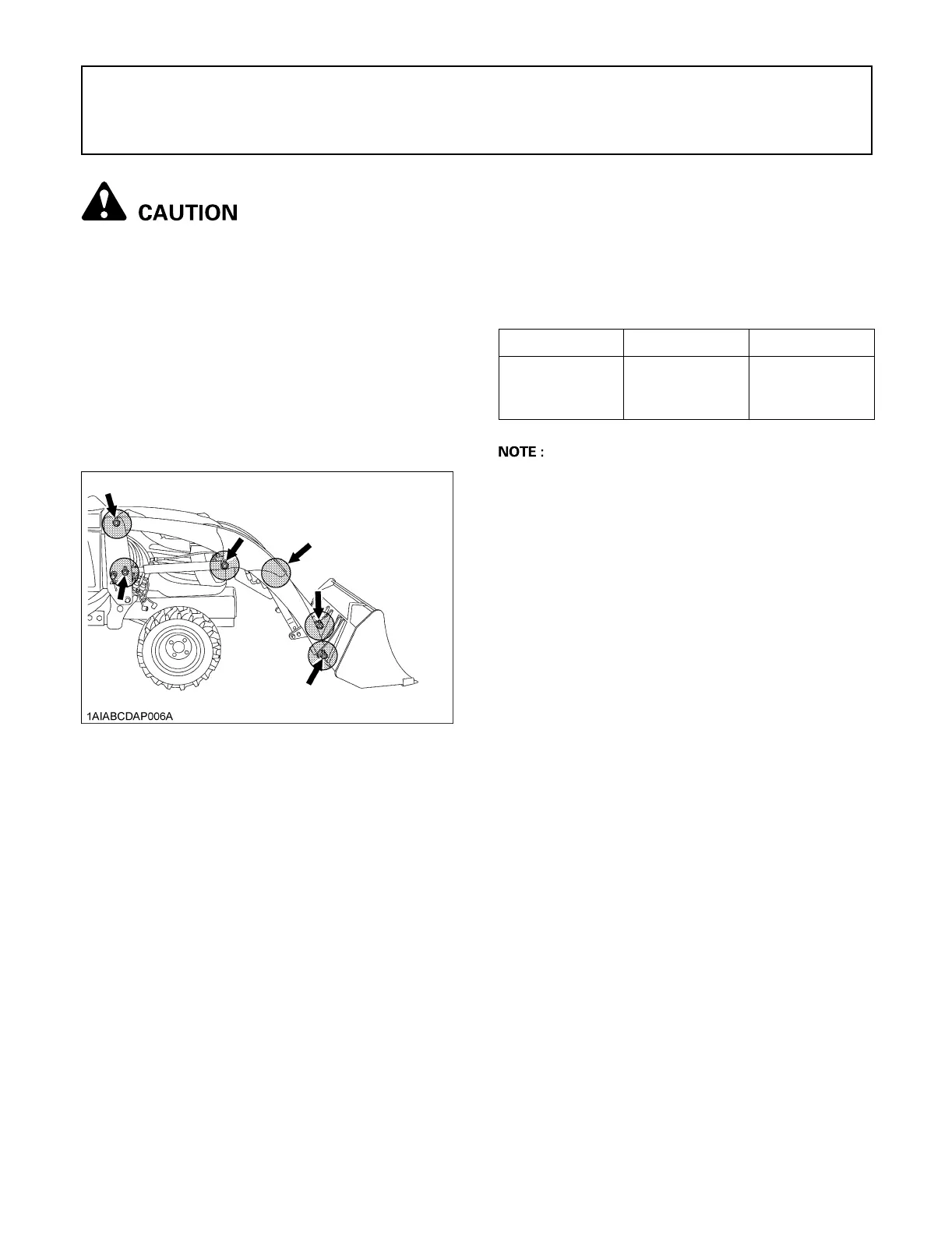

LUBRICATION

1. Lubricate all grease fittings every 10 hours of

operation. Also, lubricate joints of control lever linkage

every 10 hours. High quality grease designating

"extreme pressure" and containing Molybdenum

disulfide is recommended. This grease may specify

"Moly EP" on its label.

2. Daily before operation, check the tractor hydraulic fluid

level. If low, add as described in "PERIODIC

SERVICE OF THE TRACTOR" section. Also change

the filter element and the hydraulic fluid as

recommended in "MAINTENANCE OF THE

TRACTOR" section.

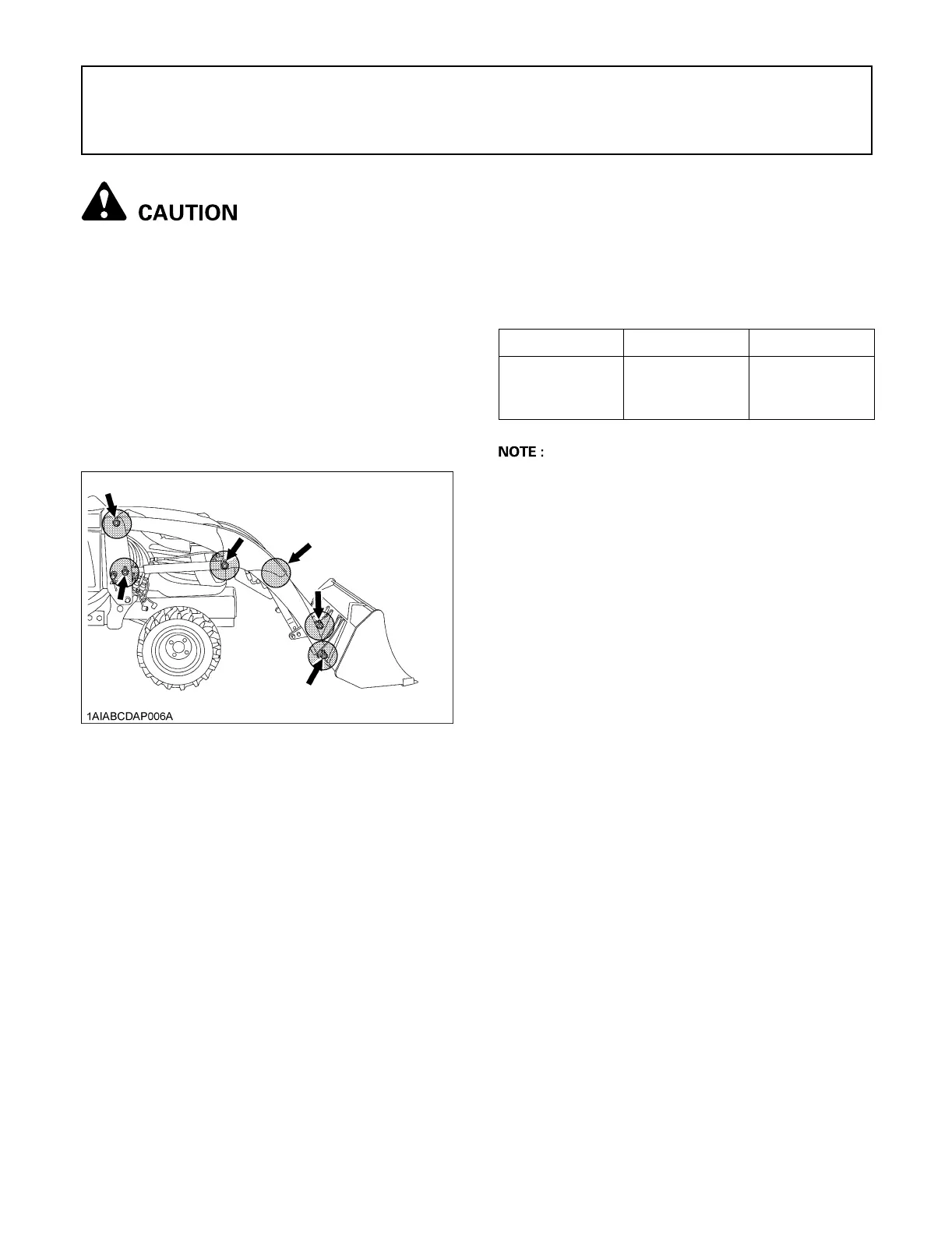

RE-TIGHTENING OF HARDWARE

After 20 to 30 hours of initial loader operation, re-tighten

all mounting bolts and nuts to the required torque value as

specified in the "Tightening Torque Chart".

BTightening Bolts and Nuts

Tighten all bolts and nuts with required torque.

A Before finally tightening all mounting hardware, start

the engine and apply down pressure to the bucket until

the loader raises the front wheels slightly, and make

sure that the mounting pins can be rotated easily.

Tighten all bolts and nuts in this position.

Location Bolt / Nut Required Torque

Main frame

M14

bolts or nuts

147 N-m

(15.0 kgf-m)

(108 ft-lbs)

Loading...

Loading...