U20-3, U25-3 WSM General

I-9

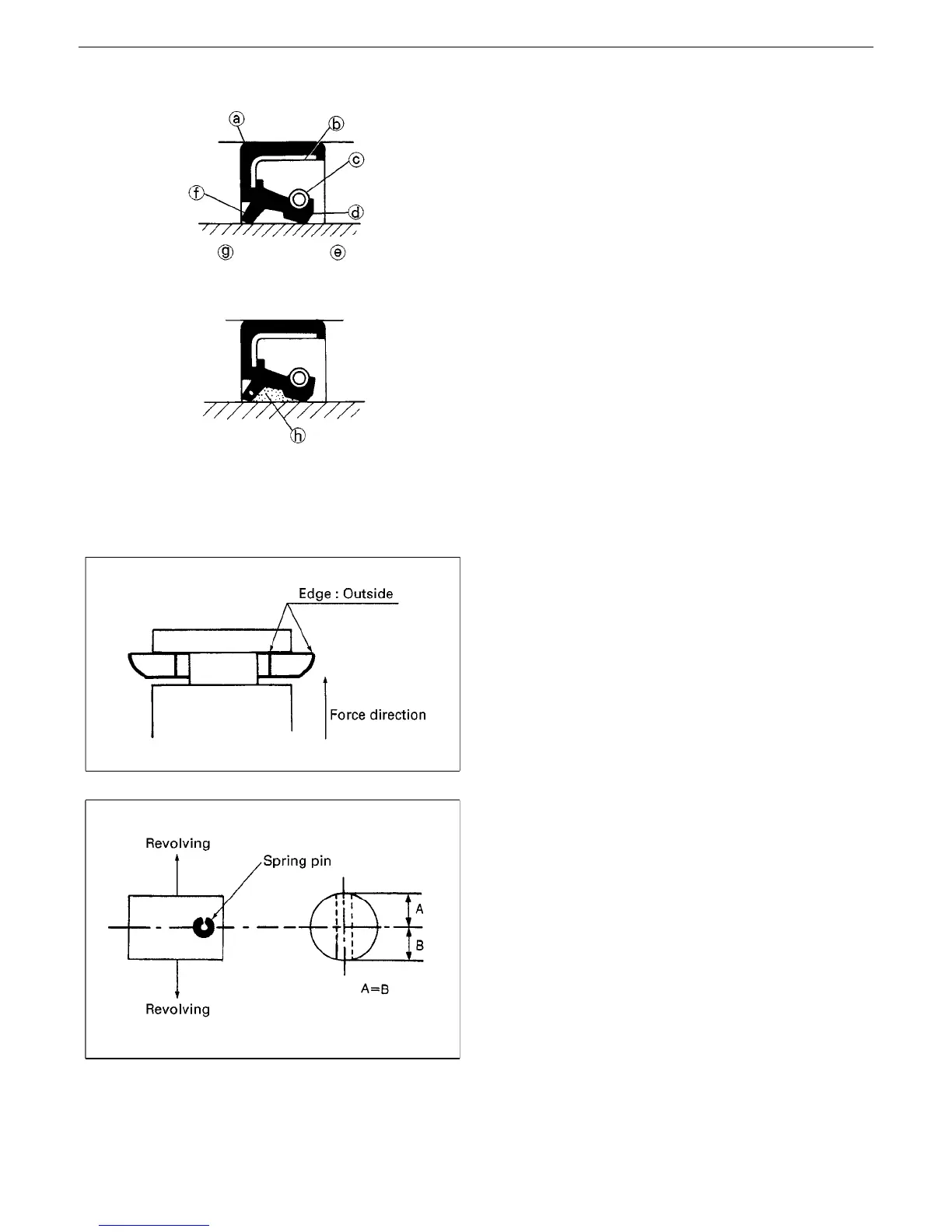

(4) Oil seal

• Do not confuse the orientation of the oil

seal lips. Direct the main lip toward the oil

chamber; in other word, toward what is to

be sealed.

• If in dry state, the oil seal may wear out

when running in the machine. To prevent

this, be sure to apply lubricant (grease)

over the lip sliding surface. If provided also

with a dustproof lip, fill the space between

this lip and the main lip with grease.

• As a rule, use a press to press-fit the oil

seal. If not available, apply a suitable tool

and tap it evenly without allowing any tilt.

Press-fit the oil seal deep down to the

bottom of the oil seal fitting boss.

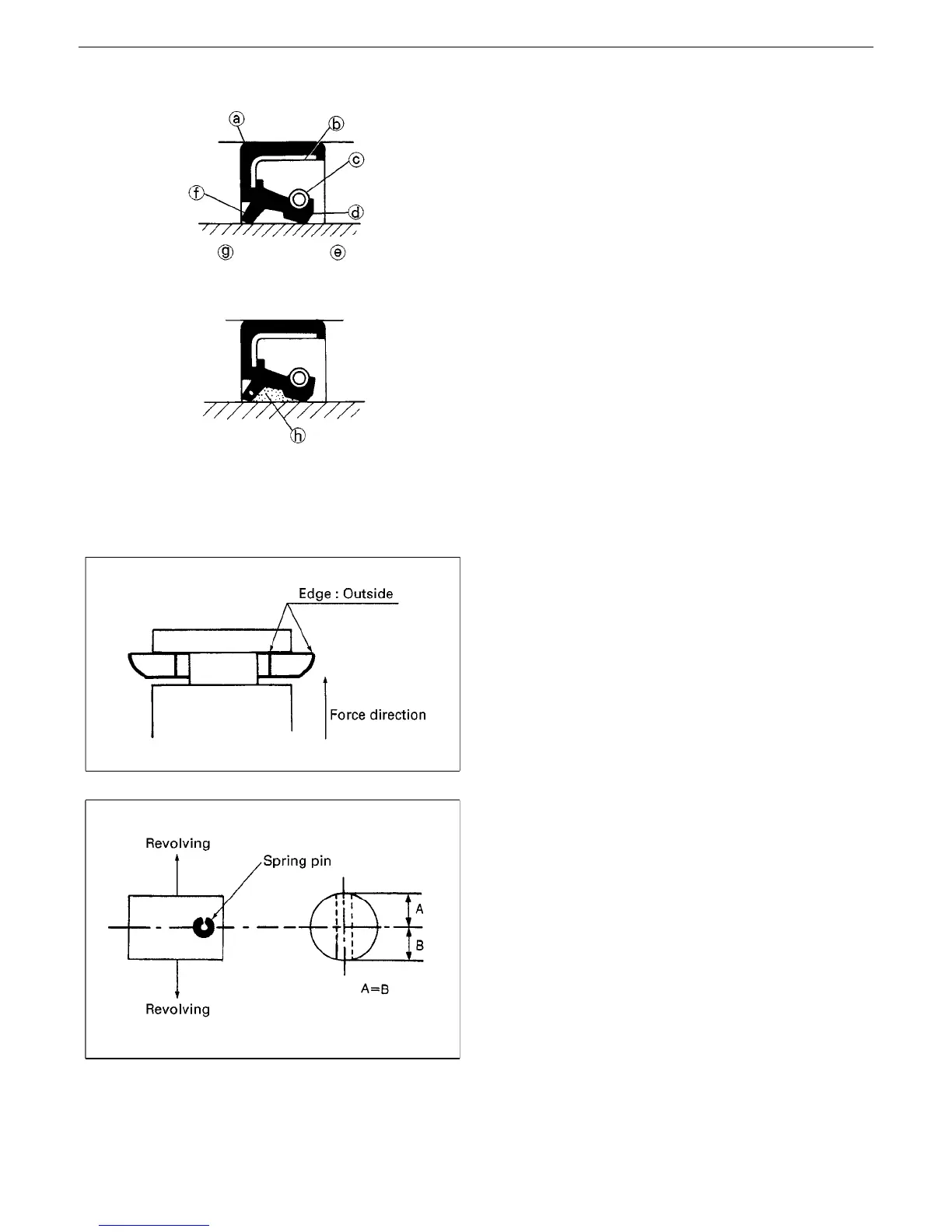

(5) Mounting the circlip

• Place the circlip with its sharp edge facing

outward (in the locking direction).

• Fit the circlip securely in the groove. For

the hole circlip in particular, install and turn

it slightly to make sure it fits well.

(6) Tapping the roll pin (spring pin)

• Place the roll pin (spring pin) with its

opening perpendicular to the load.

• Place the roll pin (spring pin) with its

opening in the turning direction.

• Evenly tap the roll pin (spring pin) into

position.

a. Packing f. Dustpans lip

b. Metal ring g. Atmosphere (outside)

c. Spring h. Grease

d. Main lip

e. Oil chamber (inside)

Loading...

Loading...