U20-3, U25-3 WSM Machine body (Service section)

II-S-19

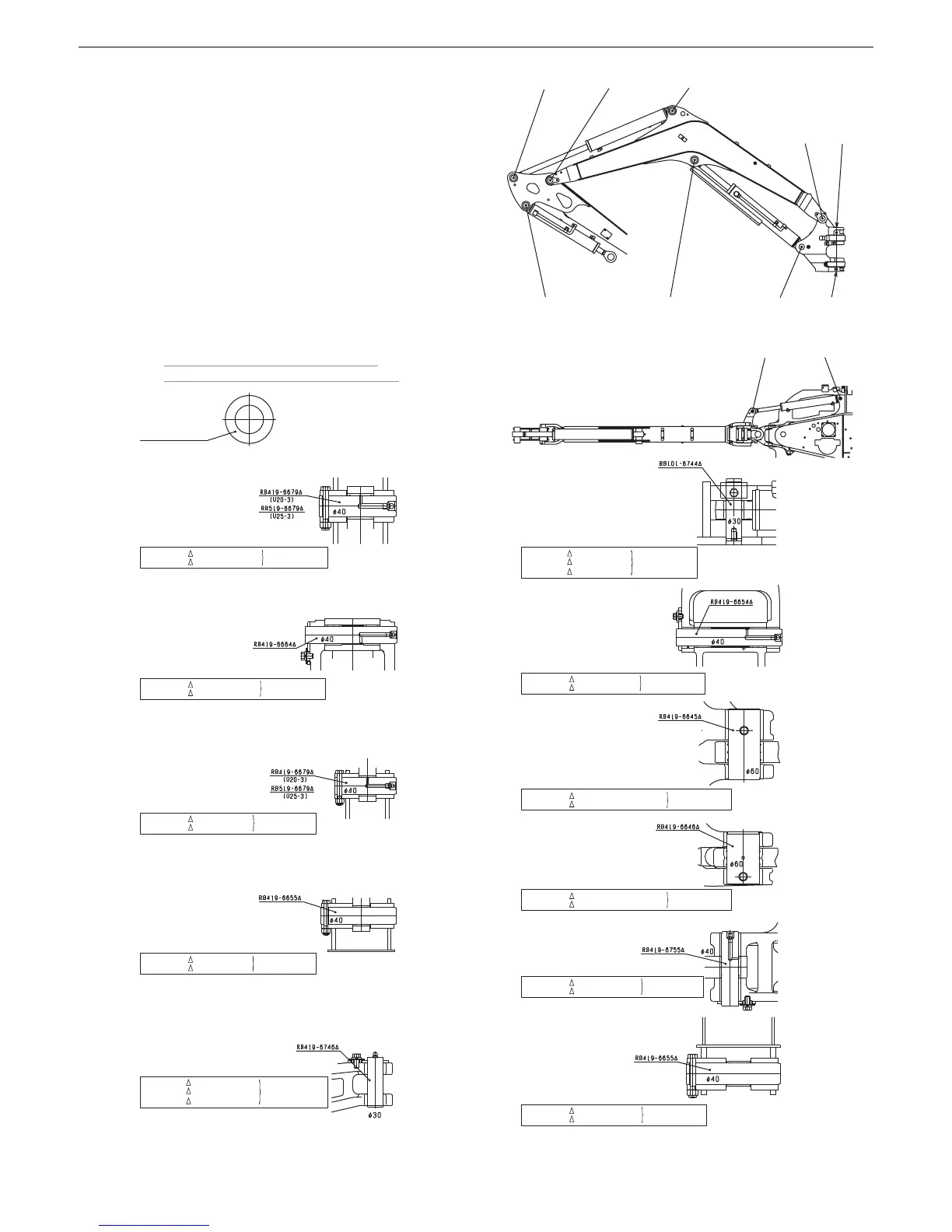

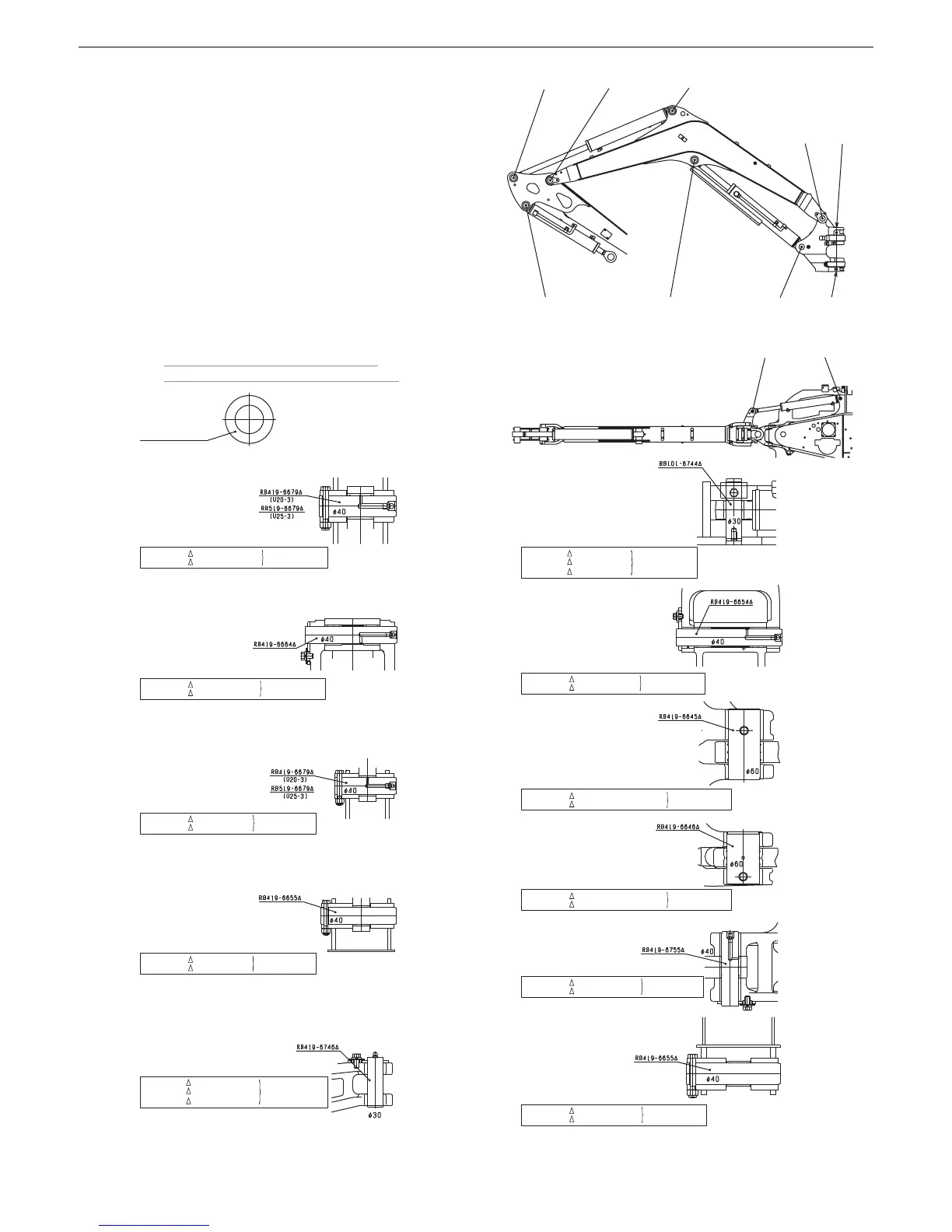

e. Installation of pin and bush

[1] Pin bush

1) Front clearances

(1) If the clearance at each support pin in the thrust

direction is larger than 0.6 mm, add a shim.

(2) Make sure the vertical clearance between the

swivel frame and swing bracket is +0.3 mm to

+1.3 mm.

(3) For the swing cylinder bottom, check the

clearance and add a shim as required.

(4) Apply grease to both sides of the thrust collars

(8) and (9).

(Molybdenum anti-seizing agent also

applicable.)

1.Apply grease to both sides.(See Figure A.)

(Molybdenum anti-seizing agent also applicable.)

Thrust collar

setup method

Apply grease.

Boom assembly

Arm cylinder

RC411-6694 Pin(0.5, 65-41)

RC411-6695 Pin(1.0, 65-41)

Use

selectively.

(4)

Arm assembly

Arm cylinder

RC411-6694 Pin(0.5, 65-41)

RC411-6695 Pin(1.0, 65-41)

Use

selectively.

(3)

Boom assembly

Arm assembly

Pin

RC411-6694 Shim(0.5, 65-41)

RC411-6695 Shim(1.0, 65-41)

Use

selectively.

(2)

Arm assembly

Bucket cylinder

RC411-6694 Shim(0.5, 65-41)

RC411-6695 Shim(1.0, 65-41)

Use

selectively.

(1)

Swing bracket

Swing cylinder

68721-6697 Shim(0.5, 60-31)

68721-6633 Shim(1.0, 60-31)

68721-6634 Shim(1.6, 60-31)

Use

selectively.

(5)

The *-marked parts are different between

U20-3EU and U25-3EU.

*

*

(1)

(11)

(5)

(10)

(6)

(9)

(8)

(7)

(4)

(2)

(3)

Boom assembly

Boom cylinder

RC411-6694 Shim(0.5, 65-41)

RC411-6695 Shim(1.0, 65-41)

Use

selectively.

(11)

RC411-6874 Thrust collar (0.5, 65-41)

68351-6645 Thrust collar (1.0, 65-41)

Use

selectively.

Swing bracket

Swivel frame(Lower)

(9)

RB411-6687 Thrust collar (0.5, 65-41)

68351-6645 Thrust collar (1.0, 65-41)

Use

selectively.

Swing bracket

Swivel frame(Opper)

(8)

Boom assembly

Swing bracket

RC411-6694 Shim(0.5, 65-41)

RC411-6695 Shim(1.0, 65-41)

Use

selectively.

(7)

Swivel frame

Swing cylinder

68721-6697 Pin(0.5, 60-31)

68051-6633 Pin(1.0, 60-31)

68051-6634 Pin(1.6, 60-31)

Use

selectively.

(6)

Swing bracket

Boom cylinder

RC411-6694 Shim(0.5, 65-41)

RC411-6695 Shim(1.0, 65-41)

Use

selectively.

(10)

Loading...

Loading...