U20-3, U25-3 WSM Machine body (Service section)

II-S-49

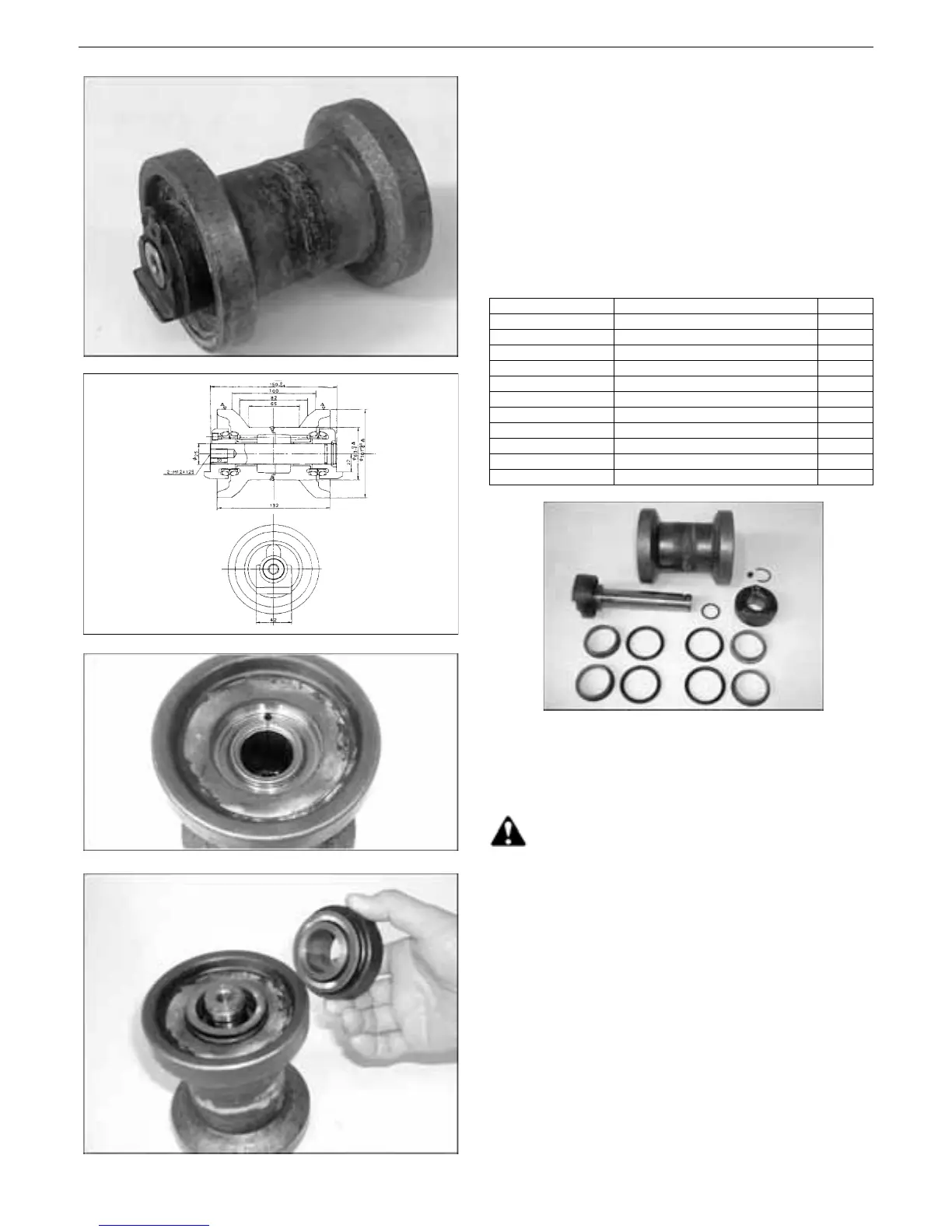

4) Track roller disassembling procedure

1. Check the roller surface and shaft for wear,

and measure the outside diameter, as

required. If out of spec, replace them with

new ones.

2. In reassembling, be careful to keep the

roller inside and incoming parts free from

dust, cuttings and other foreign matters.

3. The lube oil to pour is Engine Oil Class

SAE#30CD. Its specified amount is 50 cc.

4. The U-20-3 and U-25 are the same in

construction, but different in size.

1. Press-fit the bushing in position.

2. The bracket and shaft are press-fitted in

place at one side. A press is needed in

order to detach and attach them.

3 Apply the lube oil to the O-ring of the shaft.

CAUTION

In disconnecting the anti-fall wire, keep in mind

that the wire may pop out.

1. Check the O-ring of the floating seal for

dust and oily deposits.

Install the seal in place without twist and

tilt.

2. Apply the lube oil thinly over the seal

sliding surface.

3. Finally move the seal 2 or 3 turns to see if it

turns smoothly. This also helps form an oil

film over the seal sliding surface.

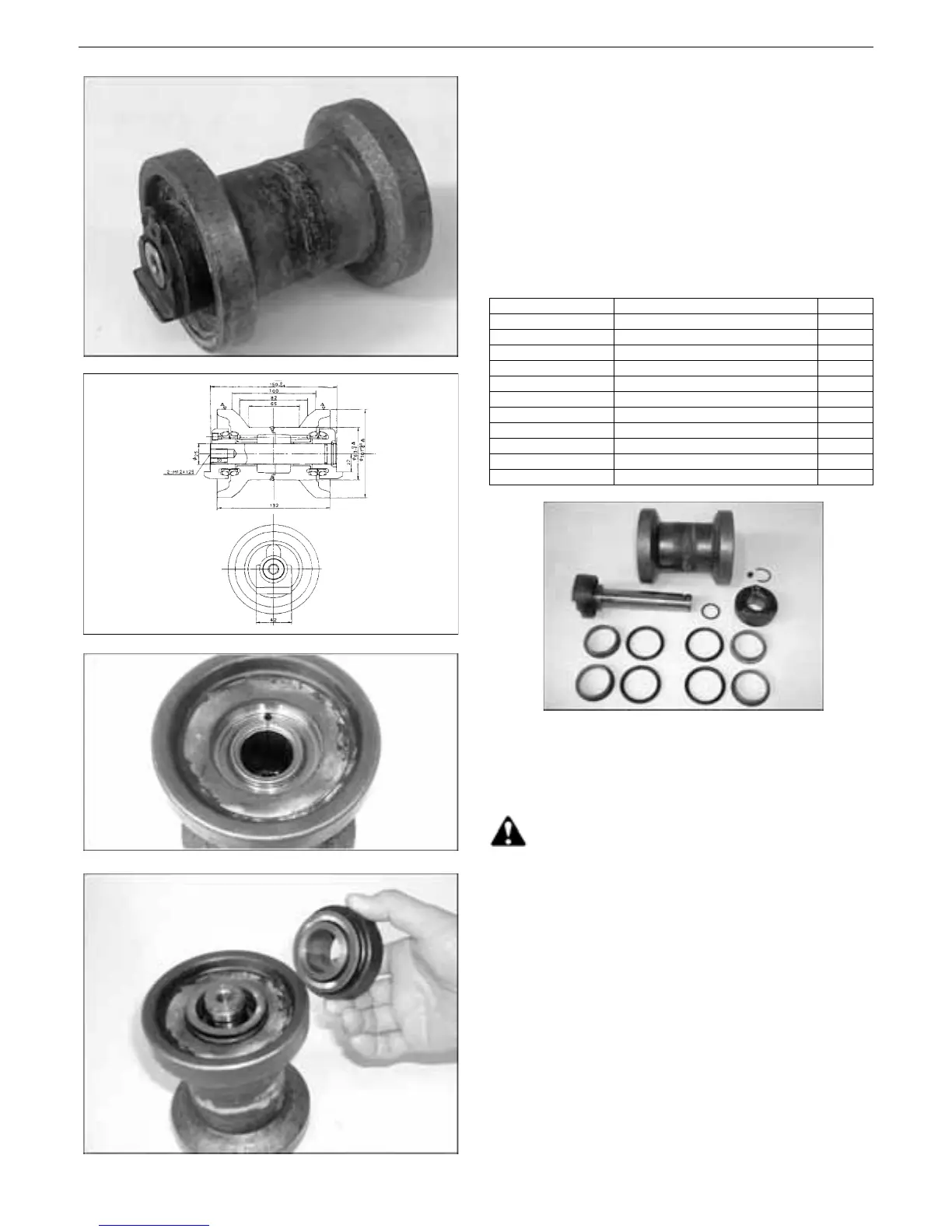

Part No. Part name Q’ty

RB511-21751 Roller 1

Roller A 1

Roller B 1

RC411-21722 Shaft 1

RB511-21711 Collar A 1

RB511-21781 Collar B 1

RC301-21961 Backup ring 2

RC301-21731 Floating seal 2

RC301-21861 Ring,stopper 1

04811-50250 O-ring 1

15521-96023 Plug 1

Loading...

Loading...