U20-3, U25-3 WSM Hydraulic system (Service section)

IV-S-66

[2] Disassembling and reassembling the pilot valve

1) Tools and tightening torque

Others

• Vapor phase inhibitor

• Kerosene

• Heat-resistant grease

• Sandpaper (#1000, #2000)

• Oilstone

•Vise

2) Maintenance standard

Note 1: It is advisable to replace the O-rings and other sealing elements at every disassembly. They

may be reused when they are found not damaged.

Note 2: When the hex socket bolt (125) has been loosened, be sure to replace the sealing washer

(121).

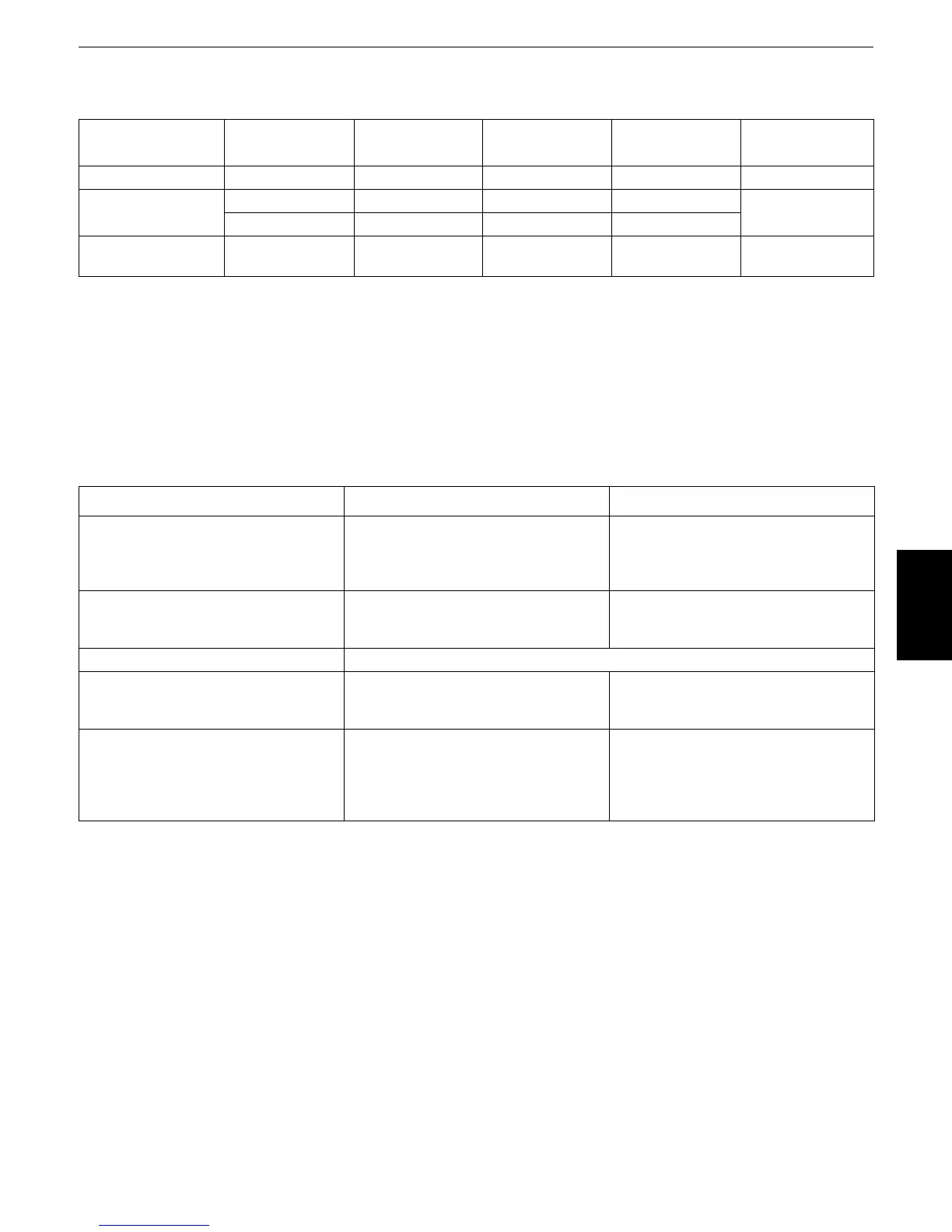

Tool Size (mm) Part No. Part name Screw size

Tightening torque

(N·m)

Hex wrench 6 125 Hex socket bolt M8 20.6 ± 1.5

Money wrench

22 312 Adjusting nut M14

68.6 ± 4.9

32 302 Disc M14

Special tool (Draw-

ing on page 17)

24 301 Joint M14 47.1 ± 2.9

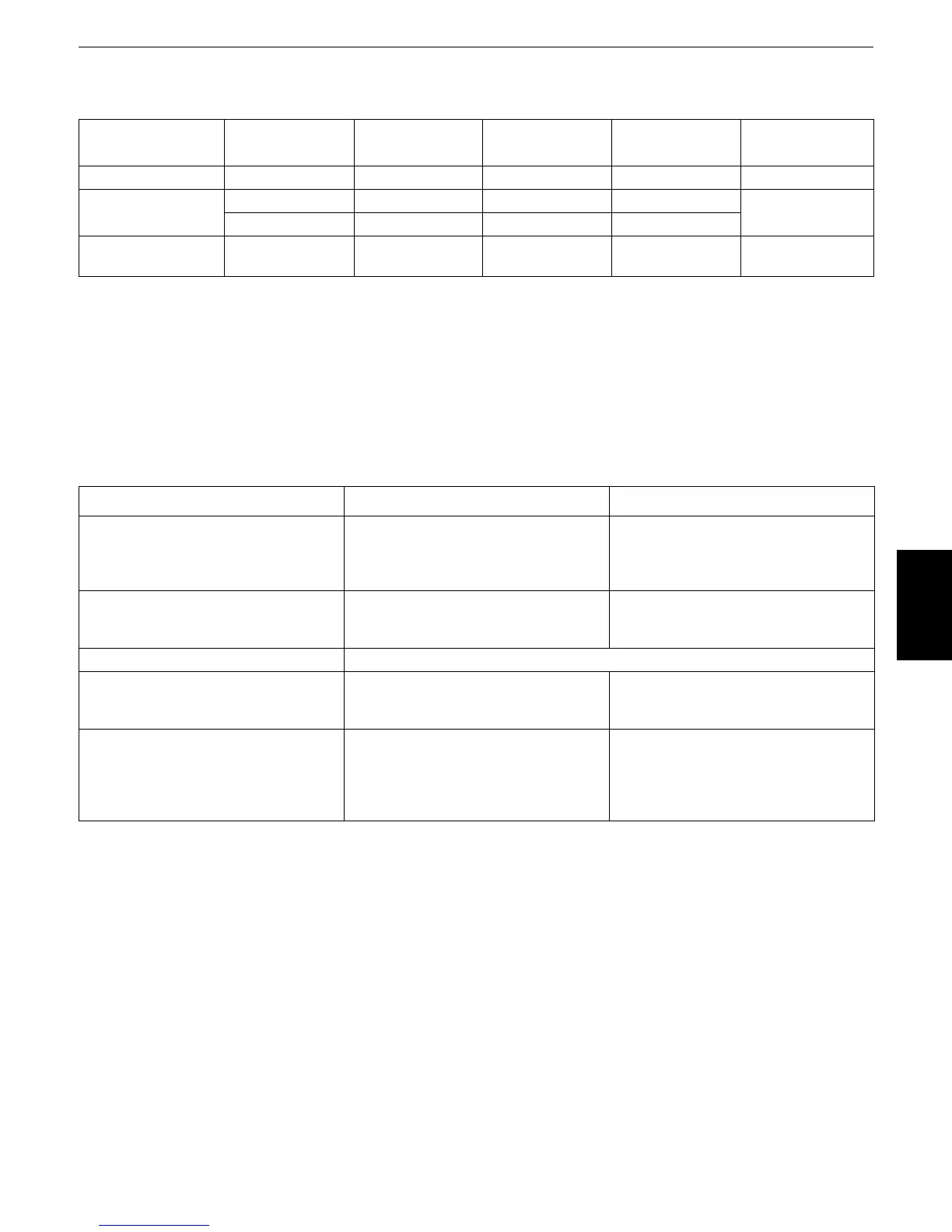

Checkpoints Criteria Remarks

Leak amount

Replace the pilot valve assembly with

new one if the oil leak exceeds 1000 cc/

min with the steering wheel at neutral or

2000 cc/min while in operation.

Conditions:

Primary pressure: 2.95 MPa

Oil viscosity: 23 mm

2

/s

Spool

If the sliding face is worn over 10 μ

more than the non-sliding one, replace

the pilot valve assembly with new one.

This amount of wear corresponds to the

above leak amount. The same condi-

tions as above are expected.

Push rod If the tip is worn 1 mm or more, replace the push rod with new one.

Loose control elements

If the disc (302) or joint (301) is worn

out and loose 2 mm or more, replace it

with new one.

If the shakiness is caused by a loose

fixture, tighten it up.

Stable operation

If unusual noise, hunting, primary pres-

sure drop, etc, occurs and it cannot be

corrected according to "Chapter 8 Trou-

bleshooting", replace the pilot valve

assembly with new one.

Loading...

Loading...