17. IGNITION SYSTEM

17-2

G-DINK 300i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• Some electrical components may be damaged if terminals or connectors are connected or

disconnected while the ignition switch is “ON” and current is present.

• When servicing the ignition system, always follow the steps in the troubleshooting on page 17-2.

•

The ignition timing cannot be adjusted since the ignition control module is already adjusted in

factory.

• The ignition control module or ECU maybe damaged if dropped or the connector is disconnected

when the key is “ ON ”, the excessive voltage may damage the ignition control module or

ECU. Always turn off the ignition switch before servicing.

• A faulty ignition system is often related to poor connections. Check those connections before

proceeding.

• Make sure the battery is adequately charged. Using the starter motor with weak battery results in

a slower engine cranking speed as well as no spark at the spark plug.

• Use a spark plug of the correct heat range. Using spark plug with an incorrect heat range can

damage the engine.

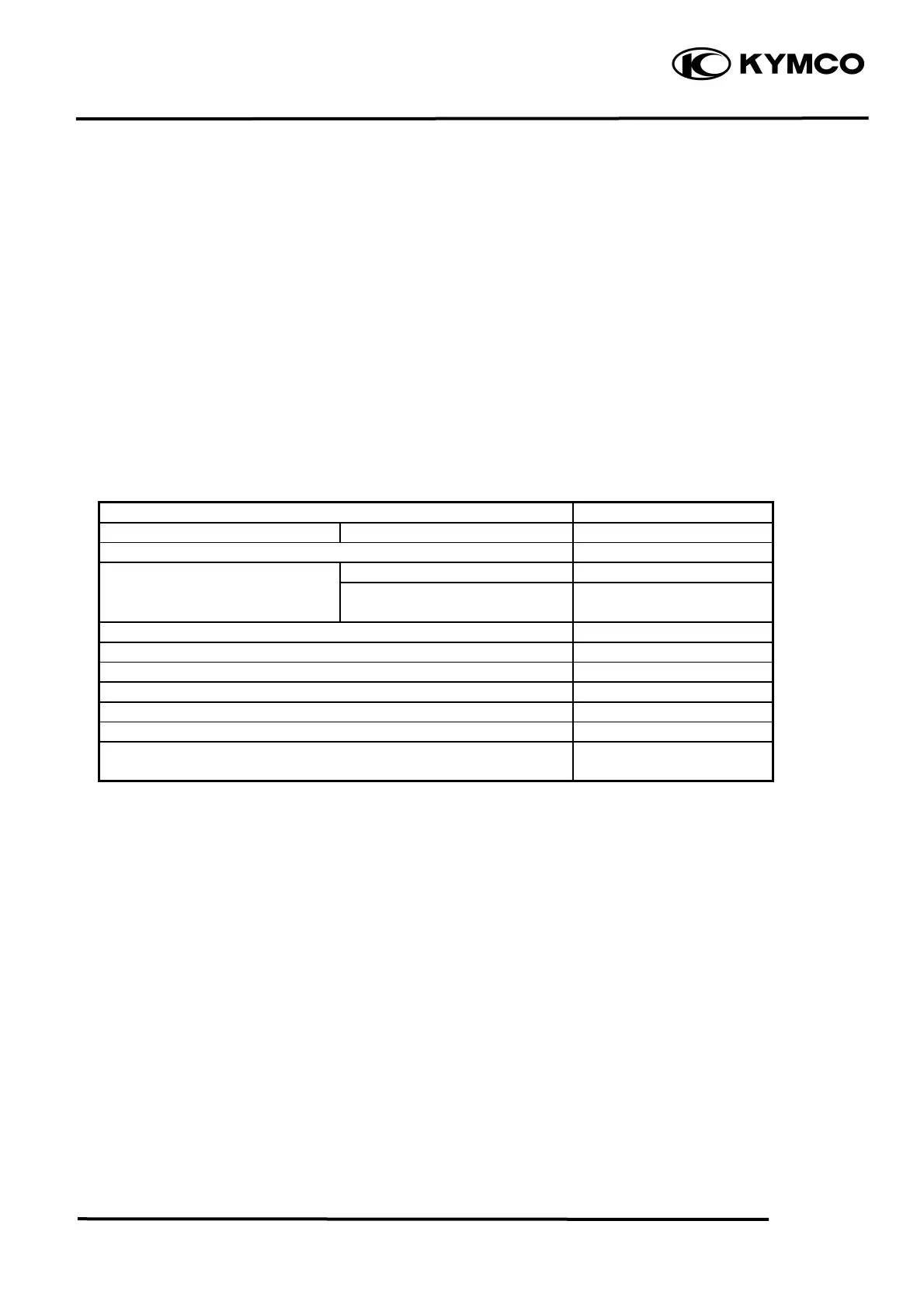

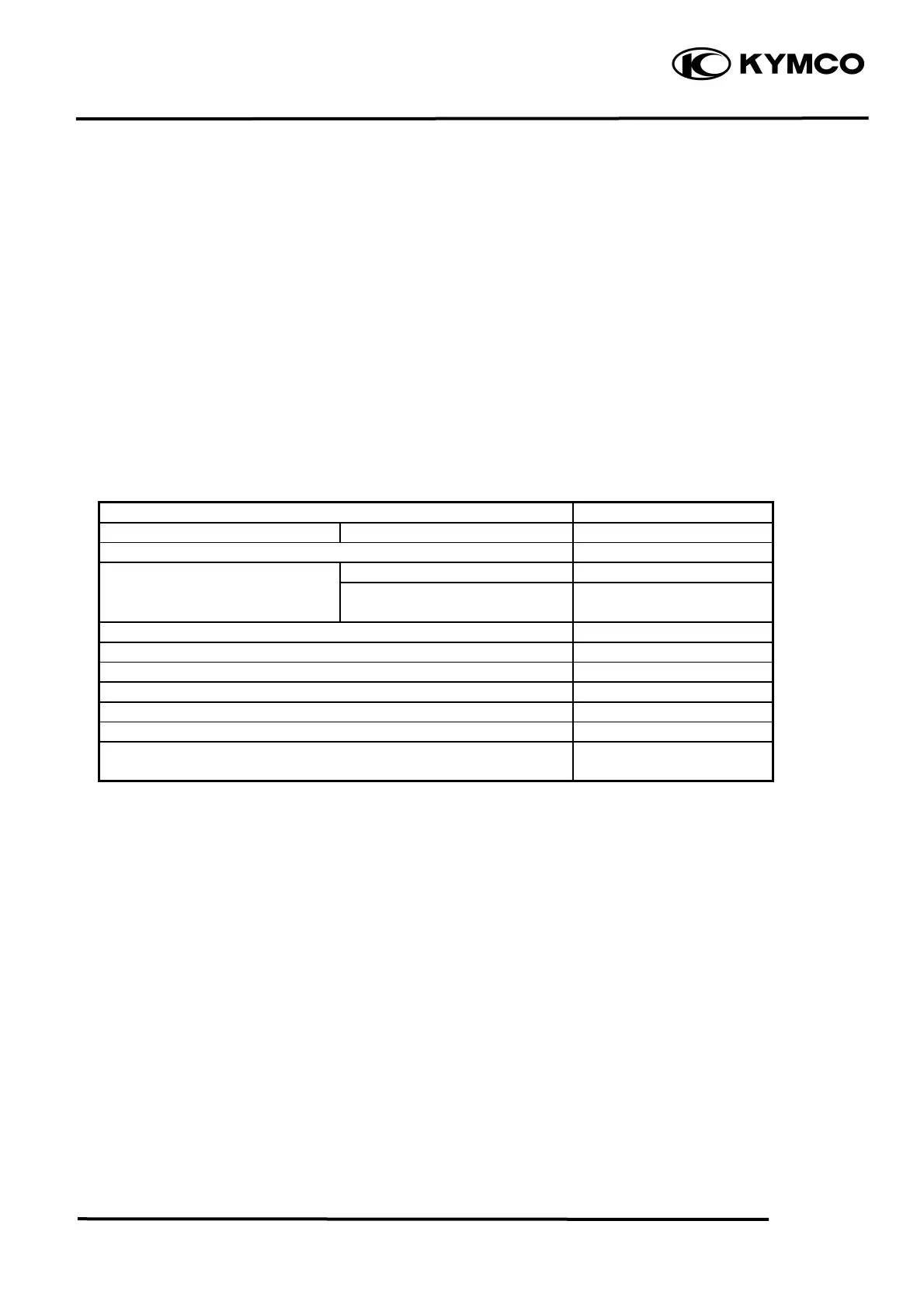

SPECIFICATIONS

Item Standard

Spark plug Standard type DPR6EA

Spark plug gap 0.6 ~ 0.7 mm

Primary coil 3.57~4.83Ω

Inductive Ignition Coil

Secondary coil without plug

cap

10.42~14.49 KΩ

Throttle Position Sensor 3500~6500Ω

Fuel Pump 1.9 Ω about

Fuel Injector 11.7±0.6Ω

Water Temperature Sensor 2.076KΩ±10% (25℃)

Oxygen Sensor ( engine warming condition ) 6.7Ω~9.5Ω

Crank Position Sensor 115Ω±15Ω

Tilt Switch

0.4V~1.4V(normal)

3.7V~4.4V (fall down)

TROUBLESHOOTING

No peak voltage

• Short circuit in engine stop switch or ignition switch wire.

• Faulty engine stop switch or ignition switch.

• Loose or poorly connected ignition control module connectors.

• Open circuit or poor connection in ground wire of the ignition control module.

• Faulty crank position sensor.

• Faulty ignition control module.

Peak voltage is normal, but no spark jumps at the plug

• Faulty spark plug or leaking ignition coil secondary current.

• Faulty ignition coil.

Loading...

Loading...