2RV/2RW/2RX/2RY/3RA-3

7-28

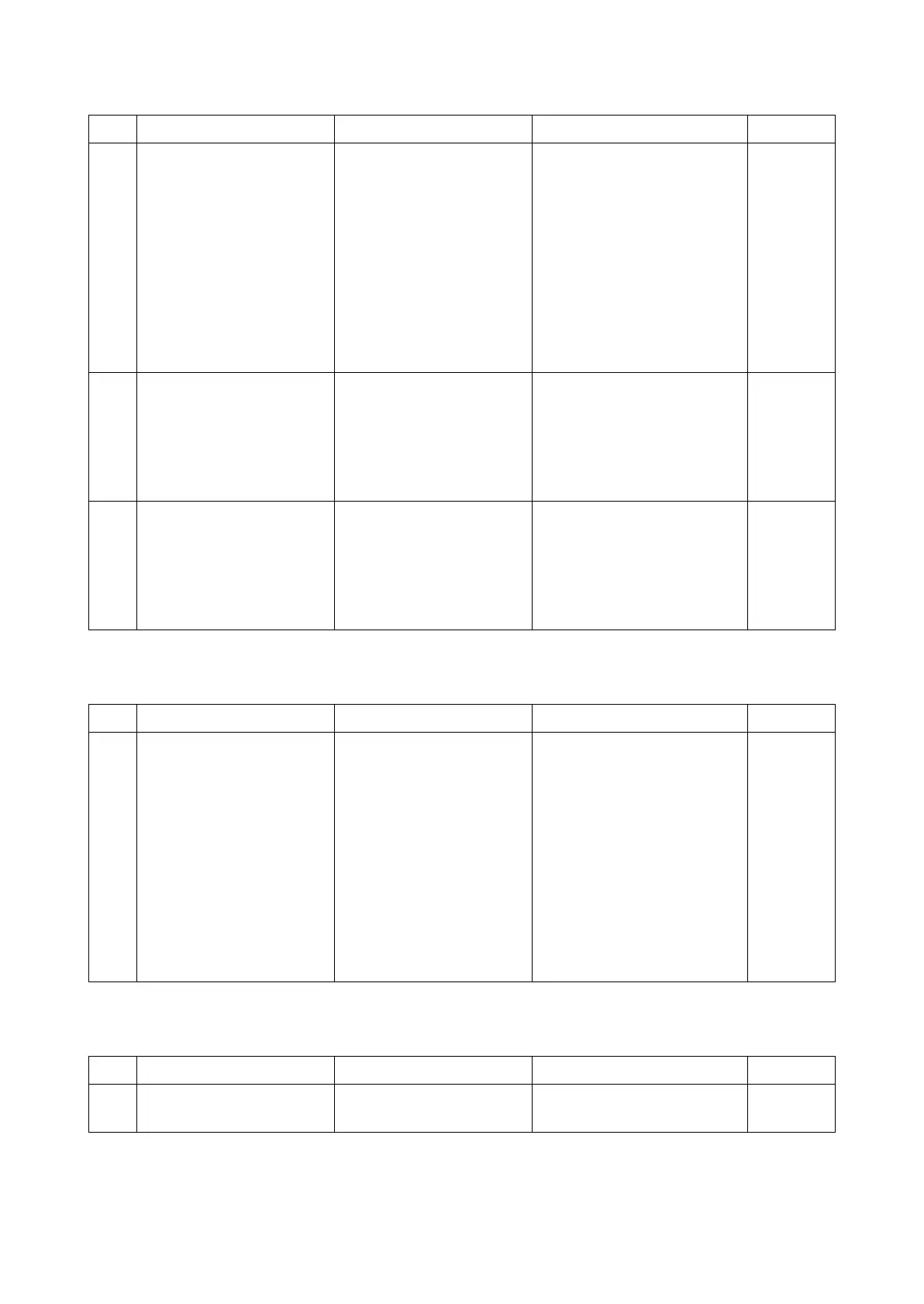

(1-9) Paper jam due to setting failure or detection failure

(1-10) Paper jam due to the static electricity

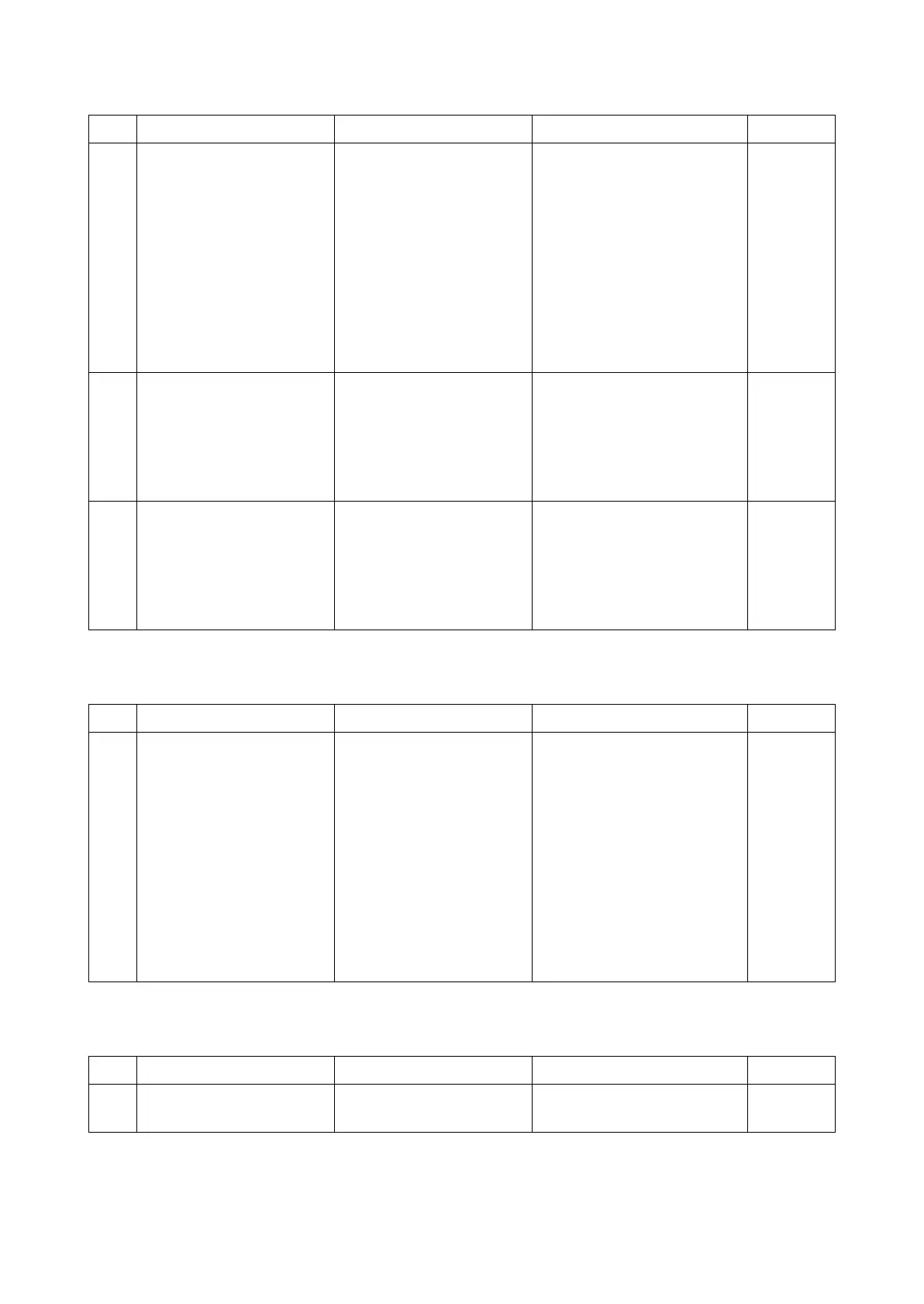

(1-11) Paper jam due to paper storage environment (high humidity)

Step Check description Assumed cause Measures Reference

1 Checking the paper lead-

ing edge margin

The leading edge margin is

not enough.

When there is no margin from

the paper leading edge to

4.0mm(+1.5/-0.0mm),

and, when the fuser jam

occurs while there is no

check line on 20mm(+/-1mm)

from the paper leading edge

of the test pattern that is out-

put at U034,

adjust the leading margin by

executing [Lead] at U402.

2 Re-setting the guide The paper size is misde-

tected.

Align the paper width guide,

paper guide (MP tray) or PF

paper width guide (paper

feeder) to the paper size and

re-load paper (multi feed jam

factor).

3 Changing the settings Media type is not set prop-

erly.

In case the media type set-

ting mismatch against the

actual paper thickness (jam

by separation failure), set the

proper media type in the sys-

tem menu.

Step Check description Assumed cause Measures Reference

1 Checking the ground The static electricity accu-

mulates.

When the main unit is

installed in the low humidity

environment where the static

electricity easily accumulates

on the conveying guide dur-

ing the continuous printing,

check if the discharge sheet

in the exit section and the

metal guide in the transfer

section are grounded

securely. If necessary, reat-

tach the parts.

Step Check description Assumed cause Measures Reference

1 Checking the paper stor-

age place

Papers have been stored

in the improper place.

Ask users to store paper in a

dry place.

Loading...

Loading...