26

3 System Description

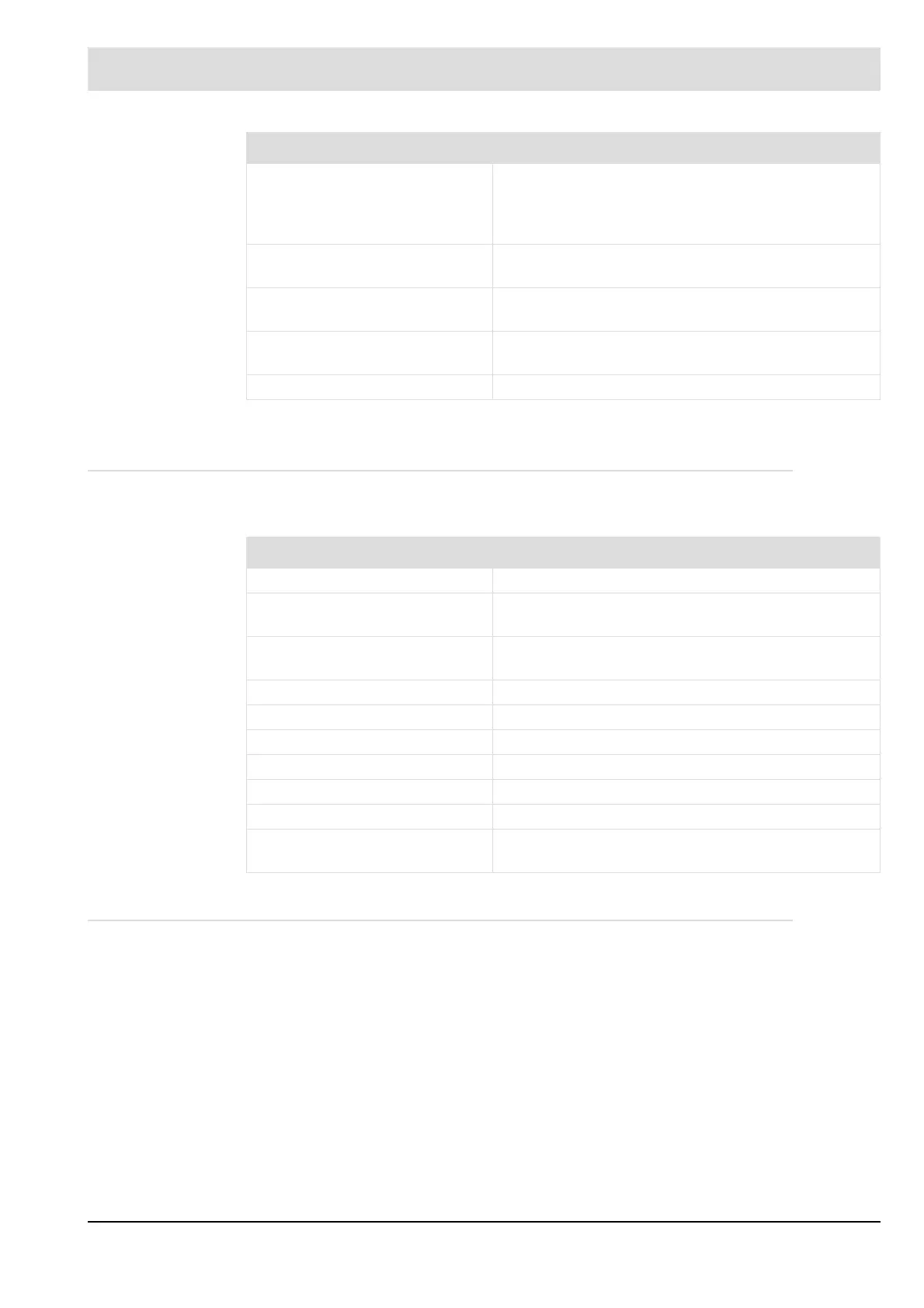

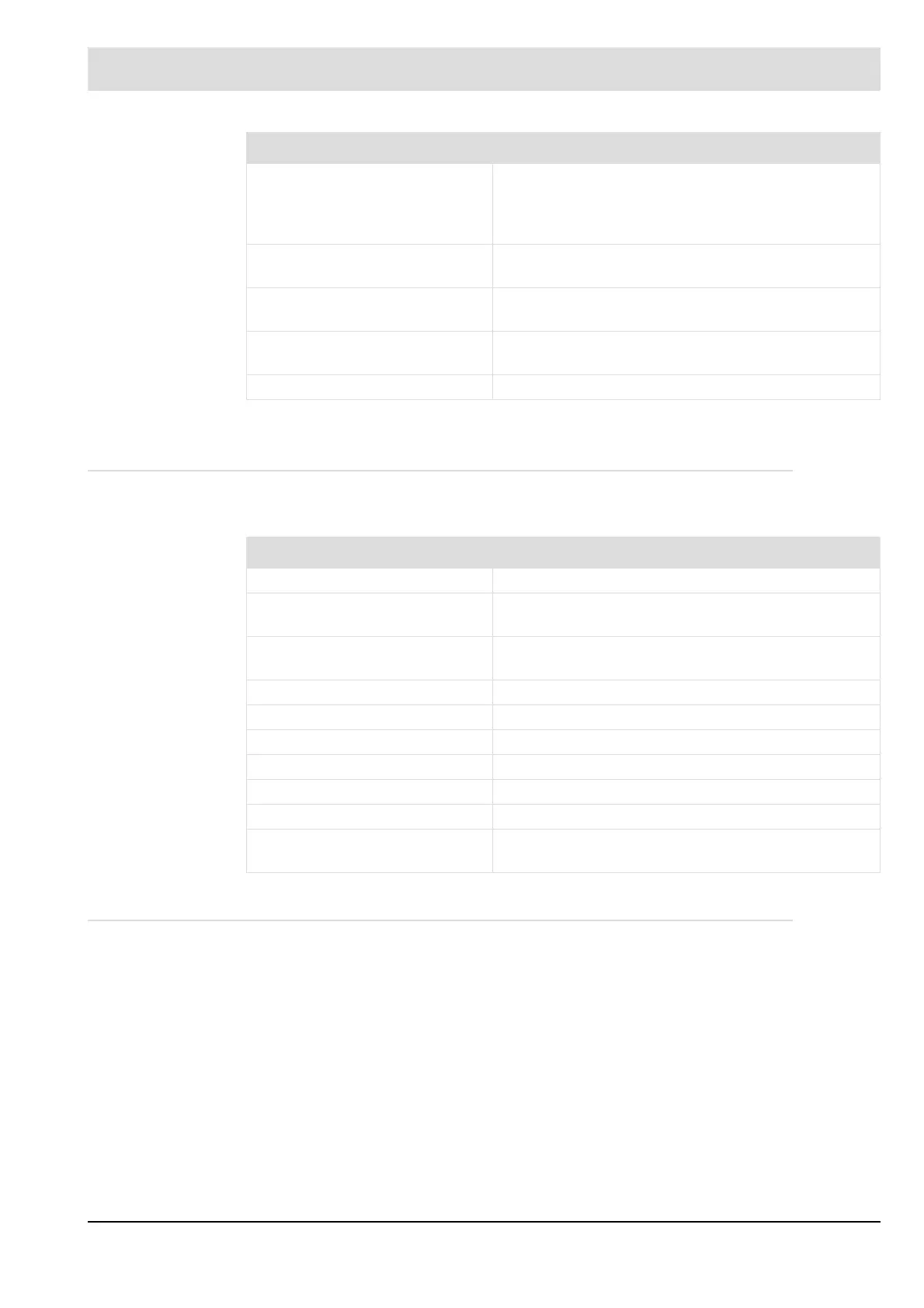

3.2.2 Digital Outputs

List of digital outputs, version V1.0.3:

3.2.3 Assignment of Input/Output Functions

(logic signals to the input/output terminals)

The input and output functions (logic signals) of the physical terminals in the CMS are as-

signed using the I/O matrix in the CMS remote software. Among these, there are signals

whose use is mandatory and those whose use is optional. To help with this assignment, the

CMS remote software provides a link matrix and a link table.

See chapter 7.3.3.4, section Configuration

Pressure before valves > min. Signal to switch off if pressure < min.

If the pressure drops below the minimum value, a

fault shut-down is initiated.

4 Signals for the chains 1 ... 4 are possible.

Safety chain input User-configurable input for a safety chain function,

see chapter 3.2.4 Chain Functions.

Curve set selection Signal for curve set pre-selection (max. 16 possible),

see chapter 3.2.5 Curve Set Selection.

Firing rate+/firing rate− These signals increase or reduce the burner firing

rate if the regular firing rate input is configured to TPS.

Soft PLC input signal User-programmable input via PLC

* The signals "Main flame present" are logically connected in series (AND operation).

Input Description

Output Description

Pilot valve 1+2 Activates the pilot valves

Fuel train 1–4

valves 1+2

Activates valve 1 and valve 2 in fuel

trains 1–4

Spark igniter per fuel train

1–4

Activates the spark igniter for fuel trains 1–4

Purge valve 1–4 Activates purge valves 1–4

Fault status signal Indicates that CMS is in fault state.

Fan Activates the fan

Fuel pump Activates the fuel pump

Atomiser steam 1–4 Activates atomiser steam valves 1–4

Pilot fan 1–4 Activates the motor for pilot fans 1–4

Activation of the mechanic

ratio control

Provides floating contacts for controlling a servo

motor in combination with a mechanic ratio control.

Loading...

Loading...