94

5 Functional Description with Process Diagrams

5.2.5 CPI/POC - Closed Position Indication/Proof of Closure

5.2.5.1 Requirements

The gas valves to be monitored must be equipped with limit switches (CPI/POC).

5.2.5.2 Required Inputs/Outputs

CPI/POC input for 1

st

main valve for each fuel

CPI/POC input for 2

nd

main valve for each fuel

For a description of the digital inputs, see chapter 3.2 Digital Input/Output Functions

5.2.5.3 Required Parameters

5.2.5.4 Functional Description

The CPI/POC input monitors the position of the main valve to the CLOSED position by a limit

switch in the main valve.

As soon as the valve opens, the limit switch contact is also opened. If this contact does not

switch correctly, a fault shut-down is initiated.

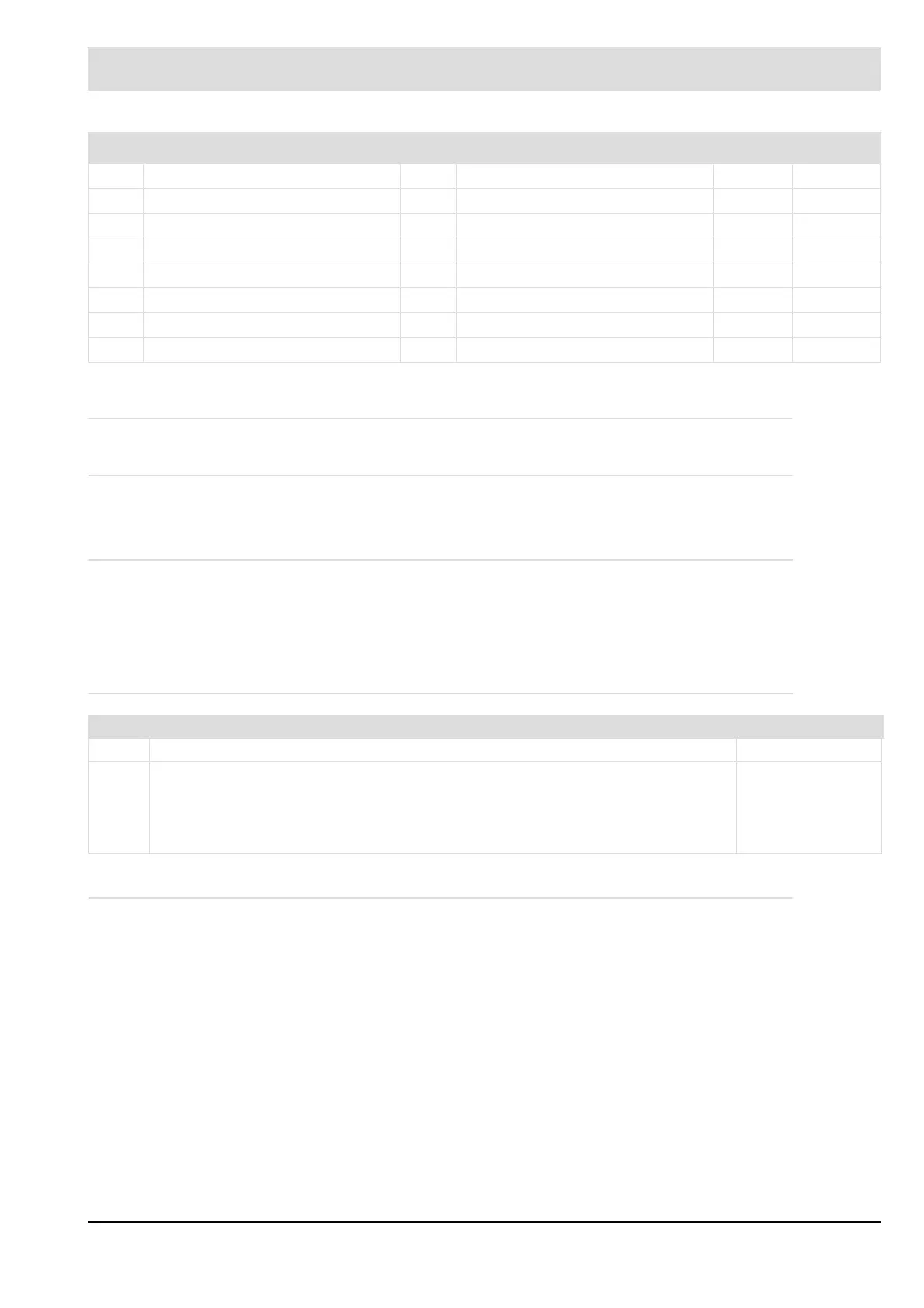

t7 1

st

safety time P305 4.0 s

t8 Stabilization time P310 3.0 s

t9 2

nd

safety time P308 3.0 s

t11 Control release delay time P380 0.0 s

t12 Block and bleed of the gas train P334 3.0 s

t13 Post-ventilation time P319 0.0 s

t22 Program monitoring time P304 600 s

t23 Irrelevance time P323 2.0 s

Signal bar Significant times and their parameters Standard

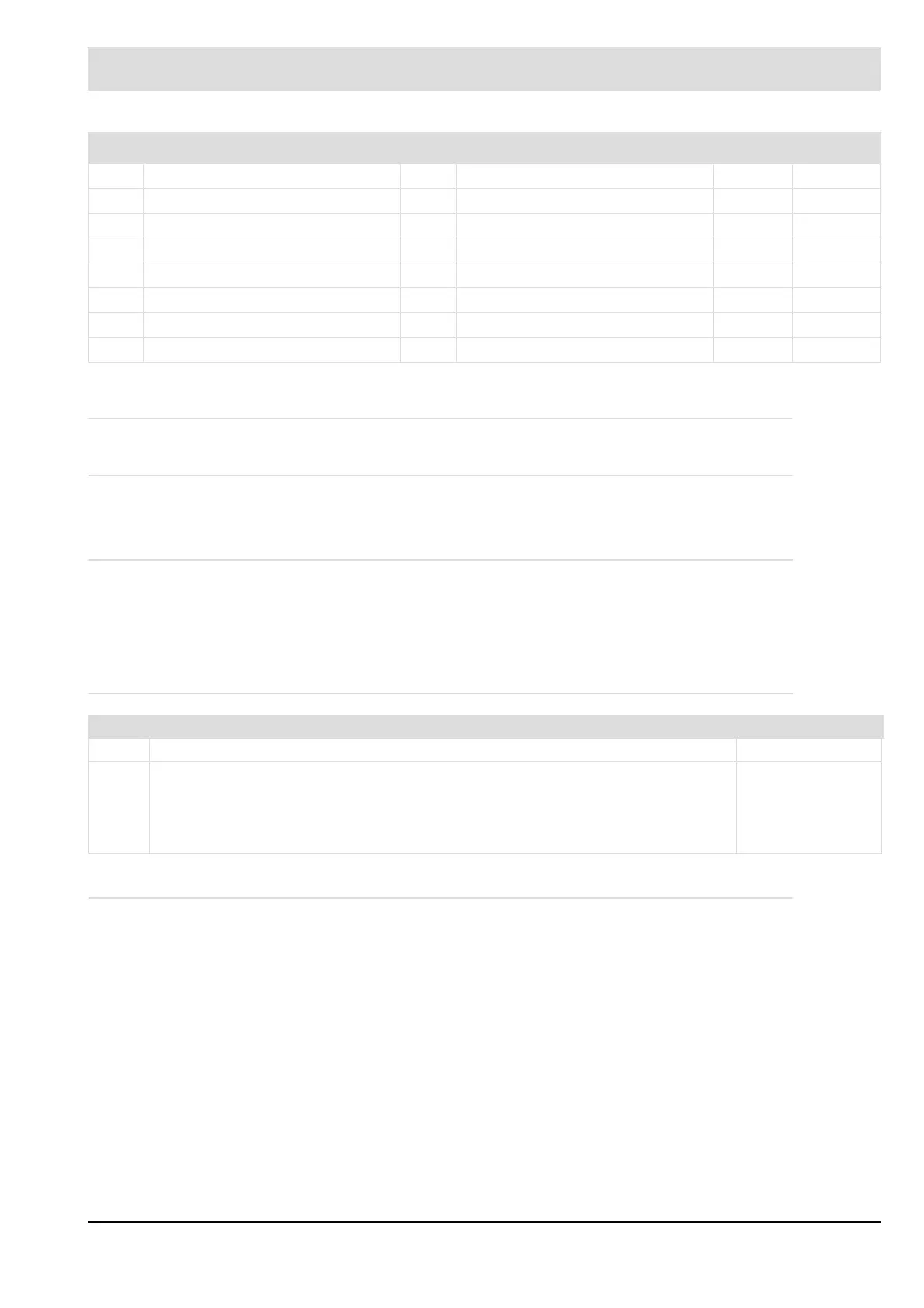

P no. Description Attributes

329 Special functions of burner sequencer V1.0.0.0

0 = gas valve 1 opens together with pilot valve in the 1

st

safety time during ignition

1 = gas valve 1 opens together with gas valve 2 in the 2

nd

safety time during ignition

Write: 2/GUI/UI

Read: 0

Default: 0

Min.: 0

Max.: 7

Loading...

Loading...