DC−bus operation

Braking operation in a drive system

Basic considerations

7

l 121

EDS700ACBA EN 5.1

7.6 Braking operation in a drive system

7.6.1 Basic considerations

If the regenerative power of a drive exceeds the storage capacity of the DC bus, the

excessive energy must be consumed or dissipated. Target of the DC bus is to use the

excessive energy for other axes.

Check for all operating situations that may occur in the DC−bus interconnetion whether the

brake power provided by the brake choppers is high enough for the maximum regenerative

power that may occur. If necessary, several power supply modules with an integrated brake

chopper can be integrated into the drive system to increase the brake power (parallel

connection).

If several brake choppers are used, the following conditions must be met:

ƒ The limiting monitoring functionalities must be considered when dimensioning the

continuous brake power for the DC bus:

– Brake chopper monitoring

– Brake resistor monitoring

ƒ The temperature monitoring of the brake resistors must lead to power−off, otherwise

the brake resistors or devices may be destroyed.

ƒ The brake choppers are protected by changing the duty cycle or switching them off

temporarily. They are automatically switched on again.

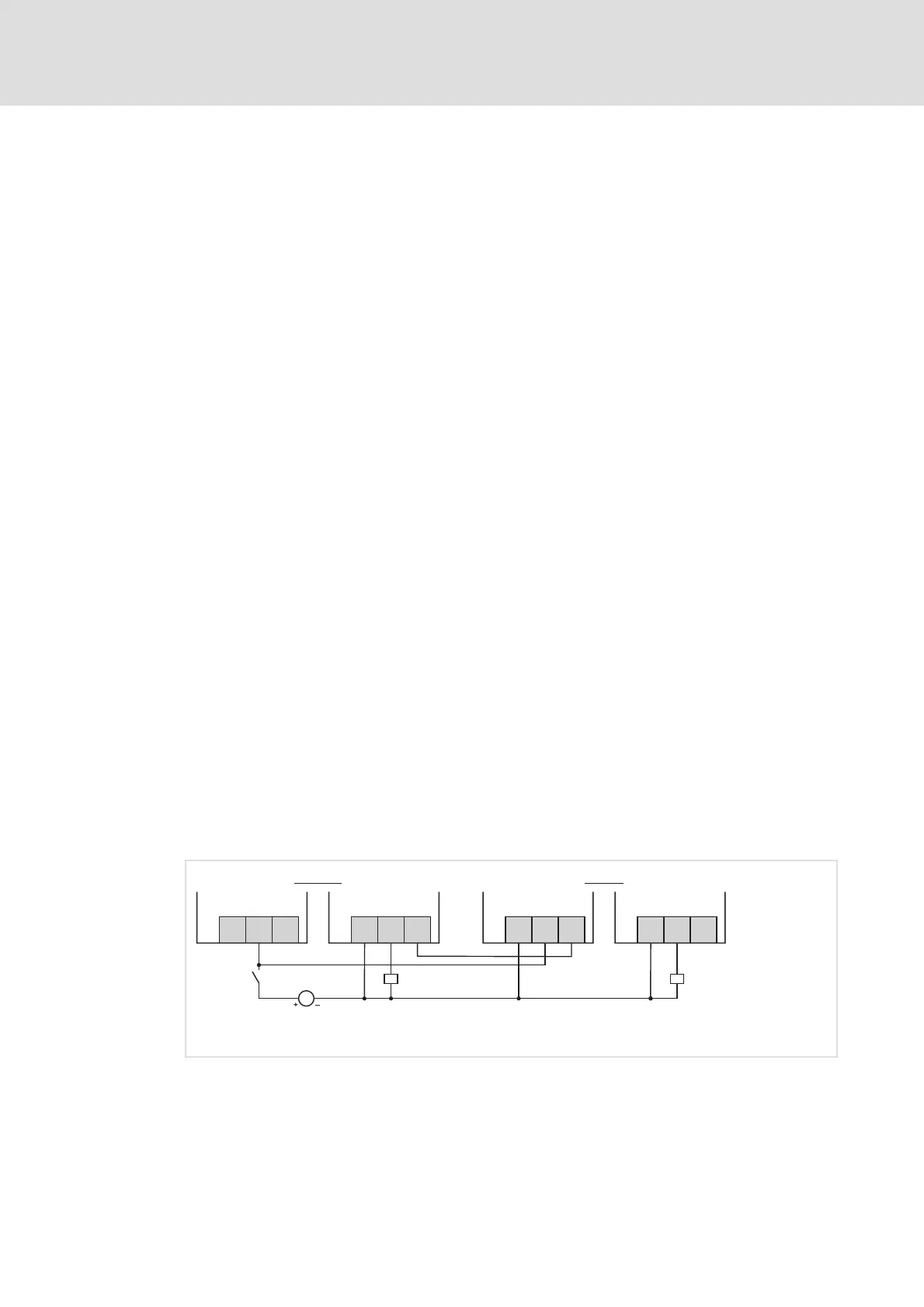

ƒ One device must be defined as "master", and the other devices must be defined as

"slaves", in order to provide for the simultaneous switching of all brake choppers,

irrespective of tolerances. How to proceed:

– For "Slave activation", apply digital input DI3 of each slave to GND potential

(GD/0 V). By this, the device−internal brake chopper switching threshold of the

slave is set to a value above the tolerance zone (790 V).

– For control by the master, interconnect digital output DO1 of the master with DI1

of the slaves. Like this, the slaves will chop on request by the master, isochronously

with the master (at 765 V).

X20.2

DO1

DO2

GD

X20.1

DI1

DI2

DI3

Master

Slave

|

X20.2

DO1

DO2

GD

X20.1

DI1

DI2

DI3

DC 24 V

(+19.2...+28.8 V)

i700S010 3

Fig. 13 Wiring of X20

X20 Connection of digital inputs and outputs at the power supply module

.1 Connector on the left−hand side

.2 Connector on the right−hand side

DIx Digital input

DOx Digital output (e.g. for controlling relays)

GD Reference potential GND