Lewmar V1-6 Windlass ref 65001201 iss.8 | 37

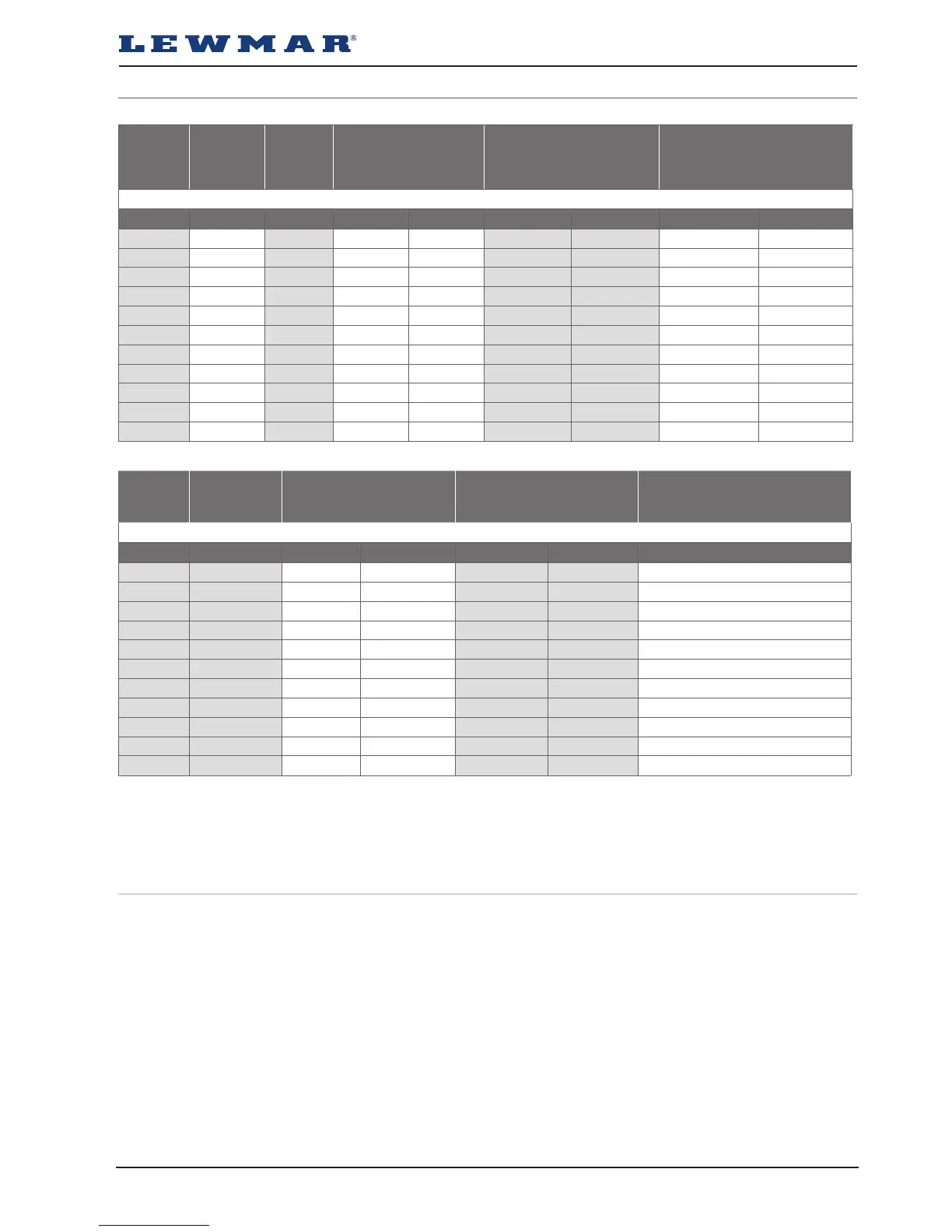

MODEL

NORMAL

CURRENT

DRAW

TOTAL WEIGHT

GYPSY ONLY

TOTAL WEIGHT

GYPSY/DRUM

CIRCUIT BREAKER

A KG LB KG LB A

V1

112 19 42 - - 90

V1 MO

112 19 42 22 48.5 90

V2

121 19 42 22 48.5 90

V2

60 19 42 24.5 54 50

V3

131 21.5 47 24.5 54 110

V3

74 21.5 47 36 79 90

V4

125 29 64 36 79 150

V4

70 29 64 38 84 110

V5

120 31 68 38 84 150

V5

60 31 68 63 139 110

V6

60 60 132 - - 150

9.6 Electric specifications

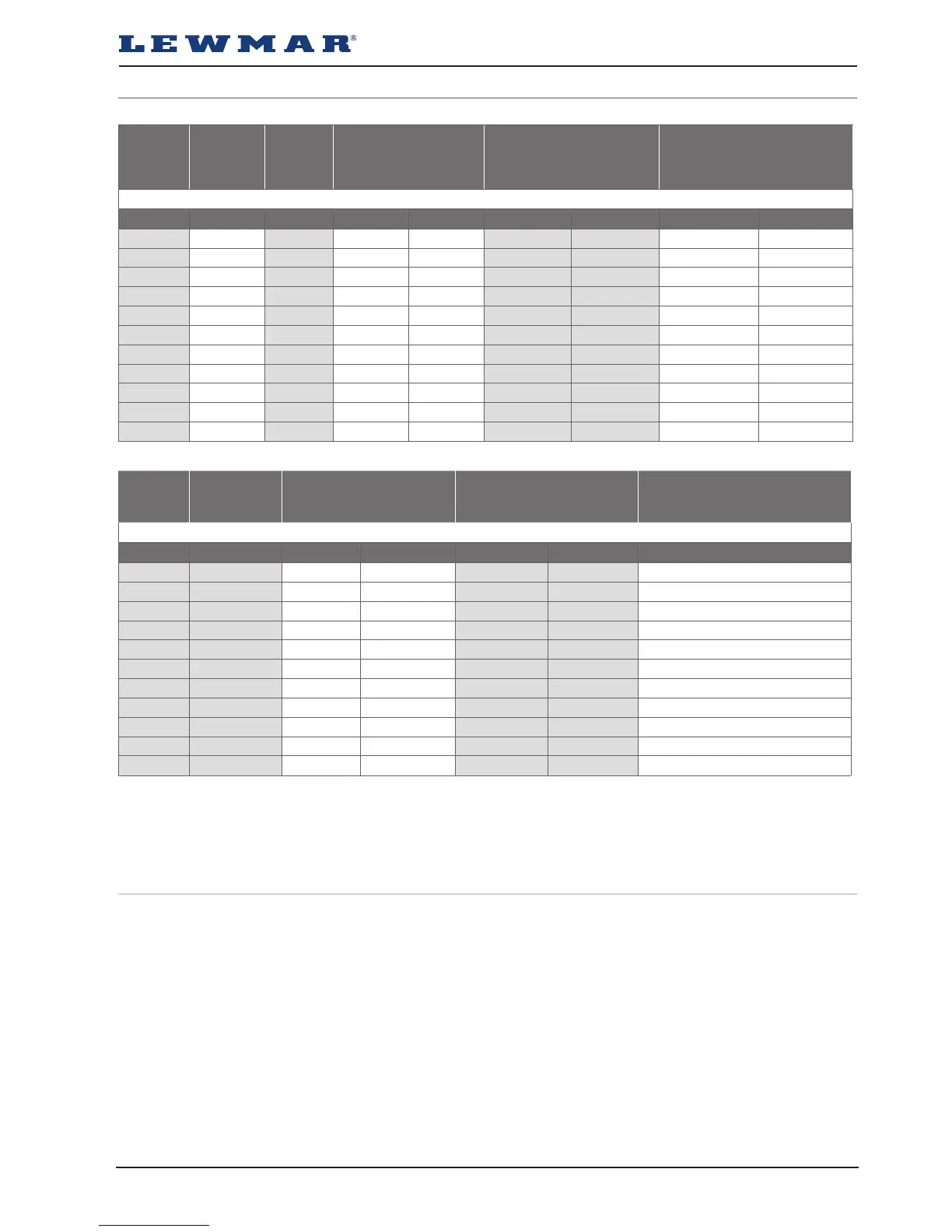

MODEL

POWER

OPTION

MOTOR TYPICAL MAX. PULL MAXIMUM LINE SPEED TYPICAL WORKING LOAD

V W KG LB M/MIN FT/MIN KG LB

V1

12 700 750 1653 28 92 188 414

V1 MO

12 700 750 1653 28 92 188 414

V2

12 700 850 1874 29 95 213 470

V2

24 900 850 1874 29 95 213 470

V3

12 1000 1025 2260 39 128 257 567

V3

24 1000 1025 2260 39 128 257 567

V4

12 1600 1360 2998 25 82 136 300

V4

24 2000 1600 3528 27 90 136 300

V5

12 2000 1860 4100 27 90 136 300

V5

24 2000 2000 4410 29 97 136 300

V6

24 2000 1800 3960 16 52 450 990

10. Trouble shooting

1. Anchor rode pays out independently while windlass is not in use.

This problem is a result of not securing the anchor rode combined with the gypsy drive cap being slack.

Tighten the gypsy drive cap using the winch handle and always secure the anchor rode independently of the

windlass when not in use.

2. Failure to operate or sluggish operation.

The majority of these problems are electrical in nature. It is essential that the proper voltage be maintained.

The proper voltage on a 12 Volt system is 13.5 Volts (24 Volt system is 26.5 Volts), constant low voltage will

damage motor.

Ensure electrical cable size is large enough to handle the current draw and keep voltage drop within

acceptable limits.

Check control switches, connections, battery condition, isolator switch, fuse and motor for operation failure.

10.1 Electric windlass

Loading...

Loading...