DATE

30-11-2001

TECO/ATL AUTHOR

BOOK CODE

1-5302-556

MODEL No.

50839

DATE OF ISSUE

01-94

REVIEW 02

APPROVAL

13

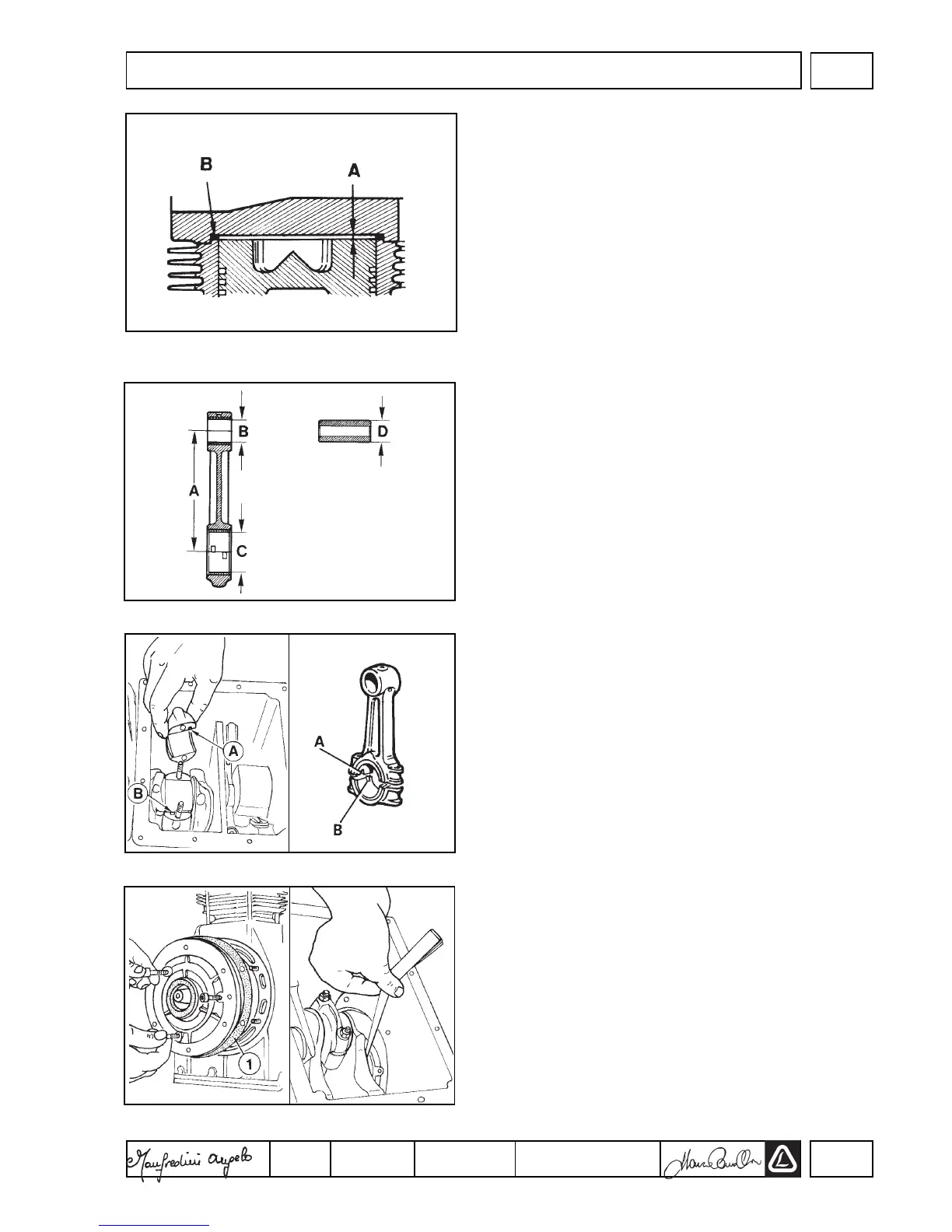

Clearance volume

A = Clearance volume

B = Head gasket

The thickness B head gasket determines the clearance volume A

which shall be 0.75 ÷ 0.90 mm for 3LD 450, 3LD 451/S, 3LD 510,

3LD 510/S and 0.80 ÷ 1.00 mm for 4LD 640, 4LD 705, 4LD 820.

Measure the piston crown position as to the cylinder surface and

chose a gasket having a suitable thickness.

Always consider that the piston at the top dead centre could be at the

same level, either under or over the cylinder.

Connecting rod equipped with bearings and piston pin

For 3LD 450, 3LD 451/S, 3LD 510, 3LD 510/S

Dimensions (mm)

A = 144.05 ÷ 145.05

B = 23.02 ÷ 23.03 (with driven and machined bearing)

C = 42.028 ÷ 42.052 (with bearing tightening at 3 Nm)

D = 27.995 ÷ 23.000

For 4LD 640, 4LD 705, 4LD 820

Dimensions (mm)

A = 162.95 ÷ 163.05

B = 28.02 ÷ 28.03

C = 55.40 ÷ 55.43

D = 27.995 ÷ 28.000

The connecting rod big end bearings are supplied either at nominal

value and diminished to 0.25 and 0.50 mm.

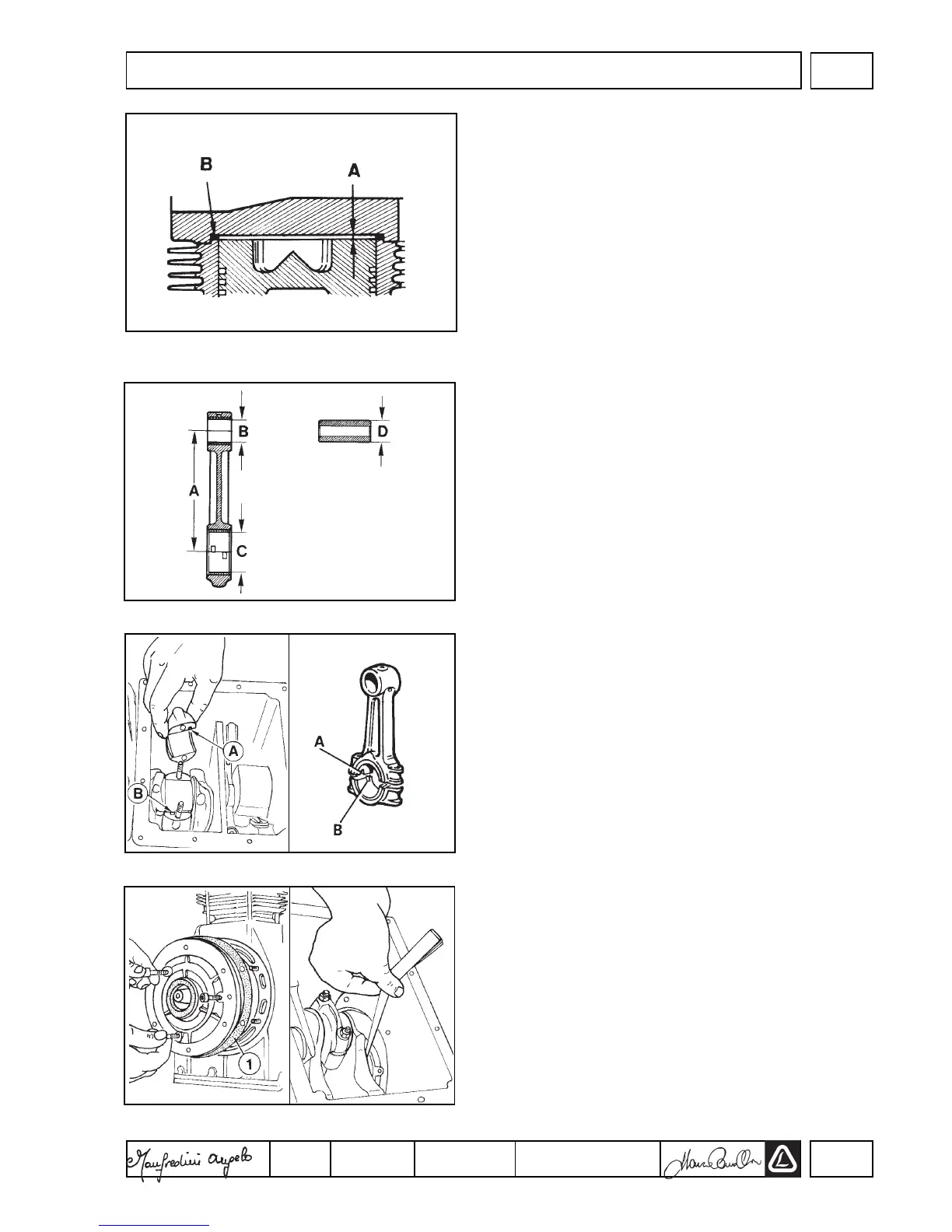

Connecting rod, big end bearings

While reassembling, the A and B centering marks should not be on the

same side.

Tighten the screws at 30 Nm for 3LD 450, 3LD 451/S, 3LD 510,

3LD 510/S and at 45 Nm for 4LD 640, 4LD 705, 4LD 820.

Main bearing on flywheel side

Extract the bearing using three screws, as per picture 38.

While reassembling, replace gasket 1. Check that the oil seal ring

is intact. Tighten the screws at 25 Nm.

Drive shaft axial clearance

After having screwed the main bearing on the flywheel, check drive

shaft axial clearance. Its value is 0.10 ÷ 0.40 mm for 3LD 450, 3LD

451/S, 3LD 510, 3LD 510/S and 0.10 ÷ 0.30 mm for 4LD 640, 4LD

705, 4Ld 820.

The adjustment is carried out by changing the gasket 1 thickness.

38

34

35

39

37

36

DISASSEMBLY/REASSEMBLY

V

Loading...

Loading...