DATE

30-11-2001

TECO/ATL AUTHOR

BOOK CODE

1-5302-556

MODEL No.

50839

DATE OF ISSUE

01-94

REVIEW 02

APPROVAL

7

3

DISASSEMBLY AND REASSEMBLY

Apart from disassembly and reassembly operations, this chapter

also includes checks, setting up, dimensions, repairs and running

instructions.

It is necessary to use LOMBARDINI original spare parts for a correct

repair.

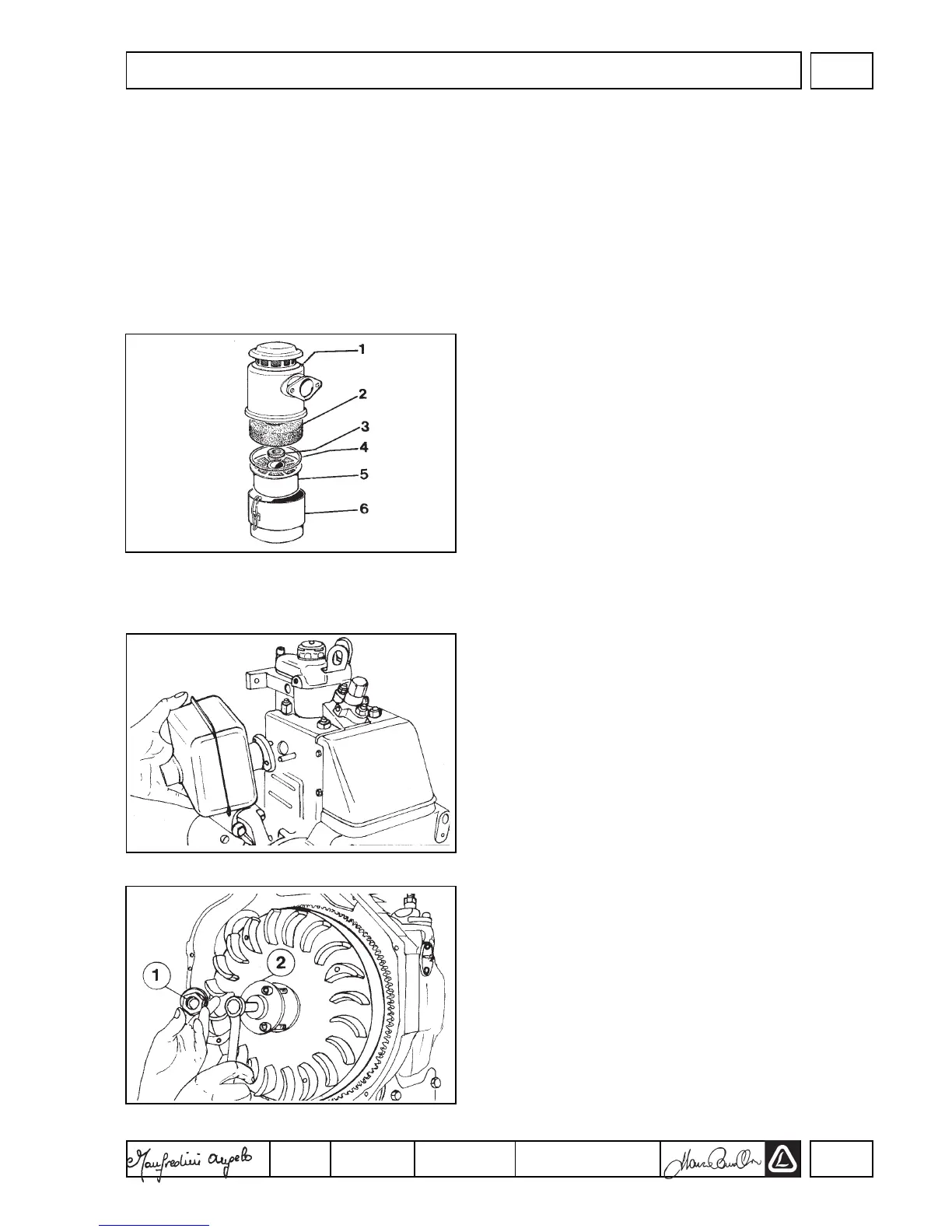

Oil-bath air filter (standard)

Oil-bath type with double filtering mass.

The lower mass is made of metal, while the upper is made of

polyurethan.

Check the gasket conditions and replace them in case they are

damaged.

Make sure that the weldings are not damaged.

Carefully clean the lower body and the filtering masses using

some gas oil, blow the lower mass with compressed air and dry

the upper mass by means of a cloth. Fill with engine oil filter to the

indicated level.

While reassembling, tighten the nuts at 25 Nm (3LD450, 3LD510,

3LD451/S, 3LD 510/S), at 30 Nm (4LD 640, 4LD 705, 4LD 820)

Details:

1 Upper body 4External sealing ring

2 Filtering mass made of polyurethan 5 Filterning mass

3 Internal sealing ring 6 Bowl

Silencer (standard)

Make sure that it is free from any carbon and oily residues, if

contaminated, replace it. While reassembling it, replace the gaskets

and tighten the brass nuts at 25 Nm.

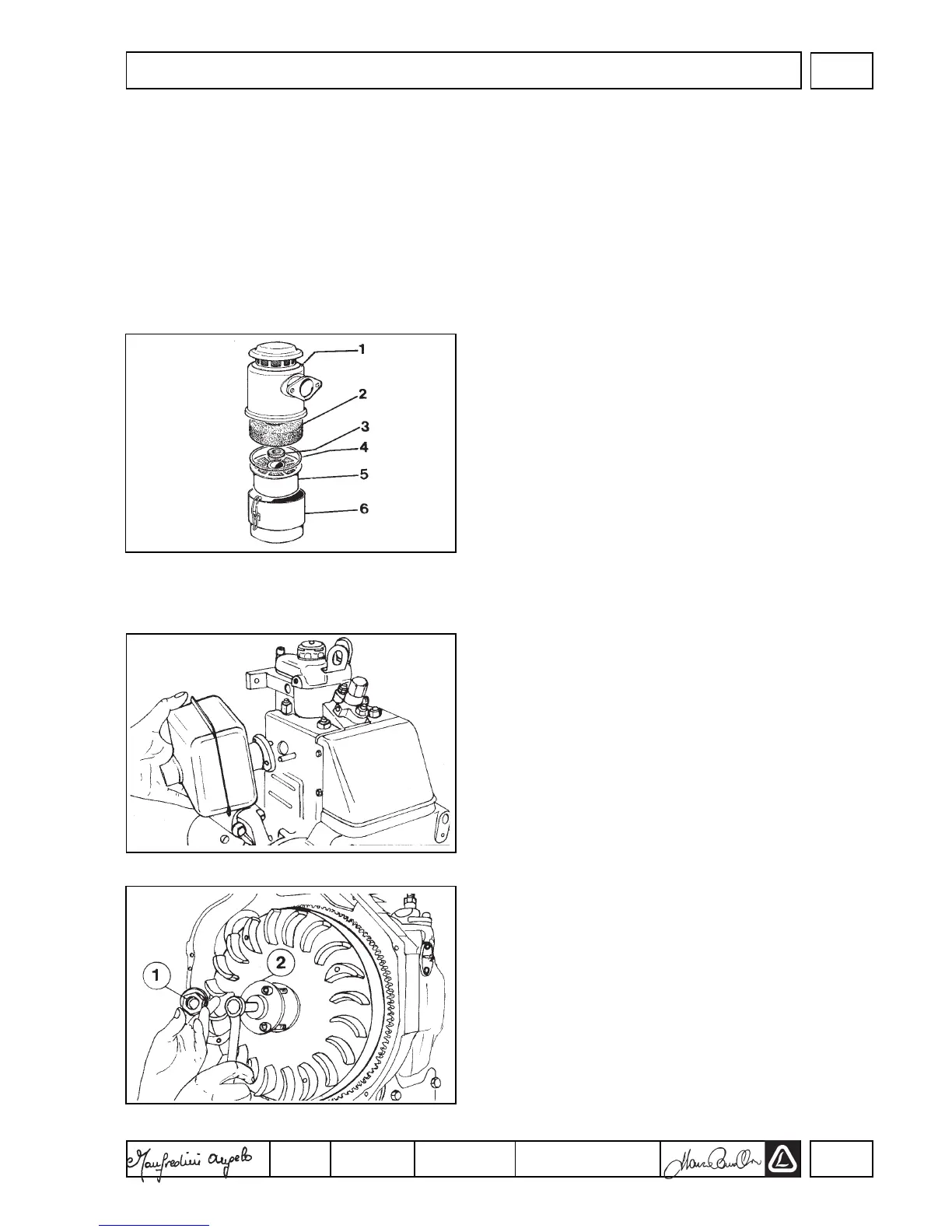

Flywheel

Clockwise unscrew nut 1 and remove the flywheel using the puller

2 Part. no. 7271-3595-050 for 3LD 450, 3LD 451/S, 3LD510, 3LD510/S,

while for 4LD 640, 4 LD 705, 4LD 820 use puller with Part. no. 7271-

3595-048.

Check that the starter ring gear, when it is present, and the conic

surface of the driving shaft coupling hole are intact.

While reassembling, tighten the screws 1 at 170 Nm for 3LD 450,

3LD 451/S, 3LD510, 3LD 510/s and at 350 Nm for 4LD 640, 4LD

705, 4LD 820.

Note: The flywheels of the left-hand engines (3LD 451/S, 3LD 510/

S) have a blading turned in the opposite direction and the nut

1 shall be anticlockwise unscrewed.

2

1

DISASSEMBLY/REASSEMBLY

V

Loading...

Loading...