- 100 -

FOCS Workshop Manual_cod. 1.5302.351_7° ed_ rev. 06

1,1

40

12

20

15

10

9

60

10

10

5

24

40

8

20*

40

80

12

**

50

15

7

360

80

25

40

***

4

80

M 3 spec.

8x1

8x1,25

12x1,25

20X1,5

6

6x1

M 10

M 6

M 6

5x0,8

8x1,5

M 10

8x1,25

M 8

M 10

10x1,25

M 6

30x1,5

10x1,25

10

12x1,5

6x1

16x1,5 sin.

10x1,25

12x1,5

12x1,5

18

TCEI 4x1,5

10x1,5

62÷63 - p. 44

116 - p. 58

131÷132 - p. 61

210÷211 - p. 92

55 - p. 43

126÷130 - p. 60

97÷98 - p. 52

50 - p. 41

167 - p. 74

39 - p. 38

181 - p. 79

68 - p. 45

146 - p. 65

90÷96 - p. 51

13÷14 - p. 32

22÷24 - p. 34

34 - p. 37

215 - p. 93

152÷153 - p. 69

113÷115 - p. 57

64- p. 44

21 - p. 34

270

270

638

Silicon

7091

270

242

242

12

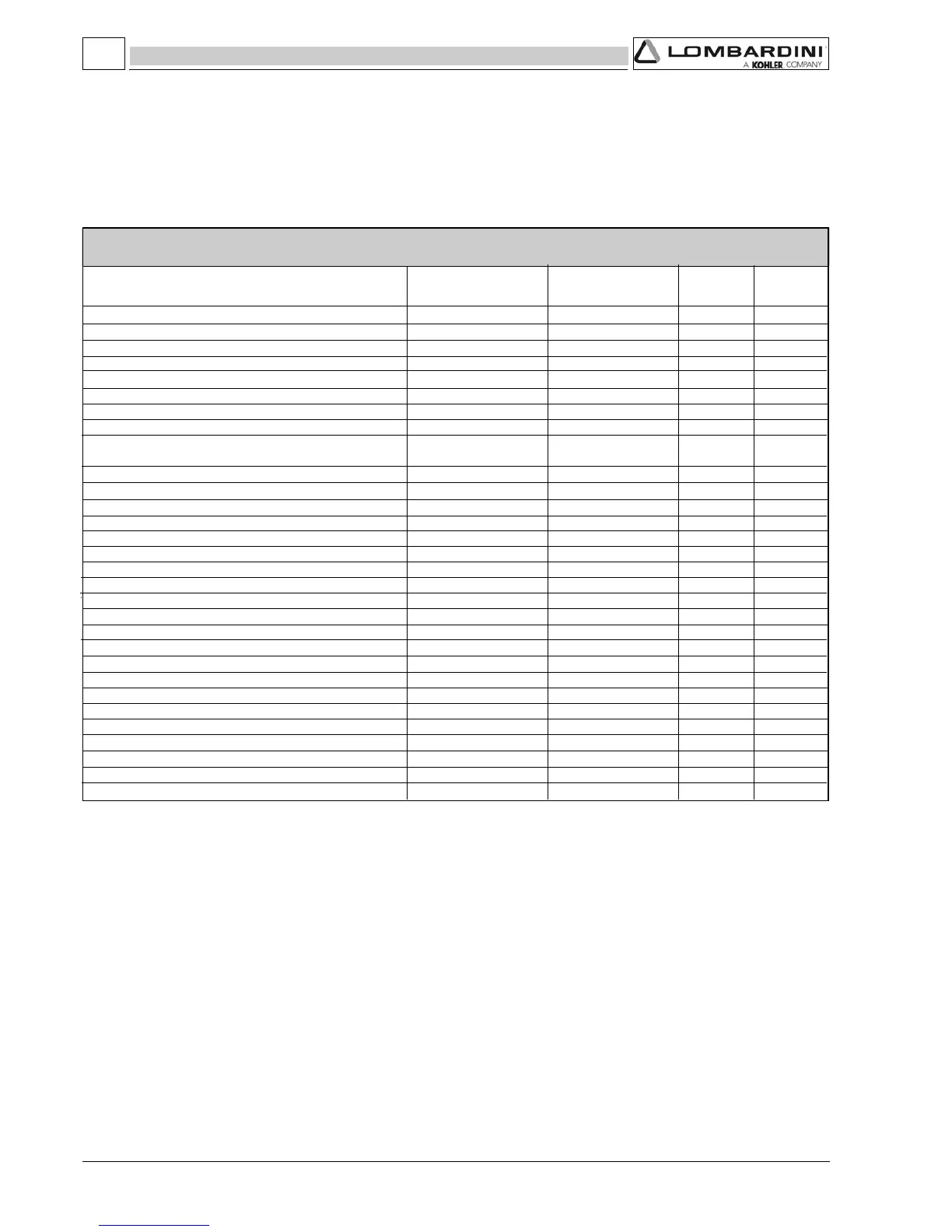

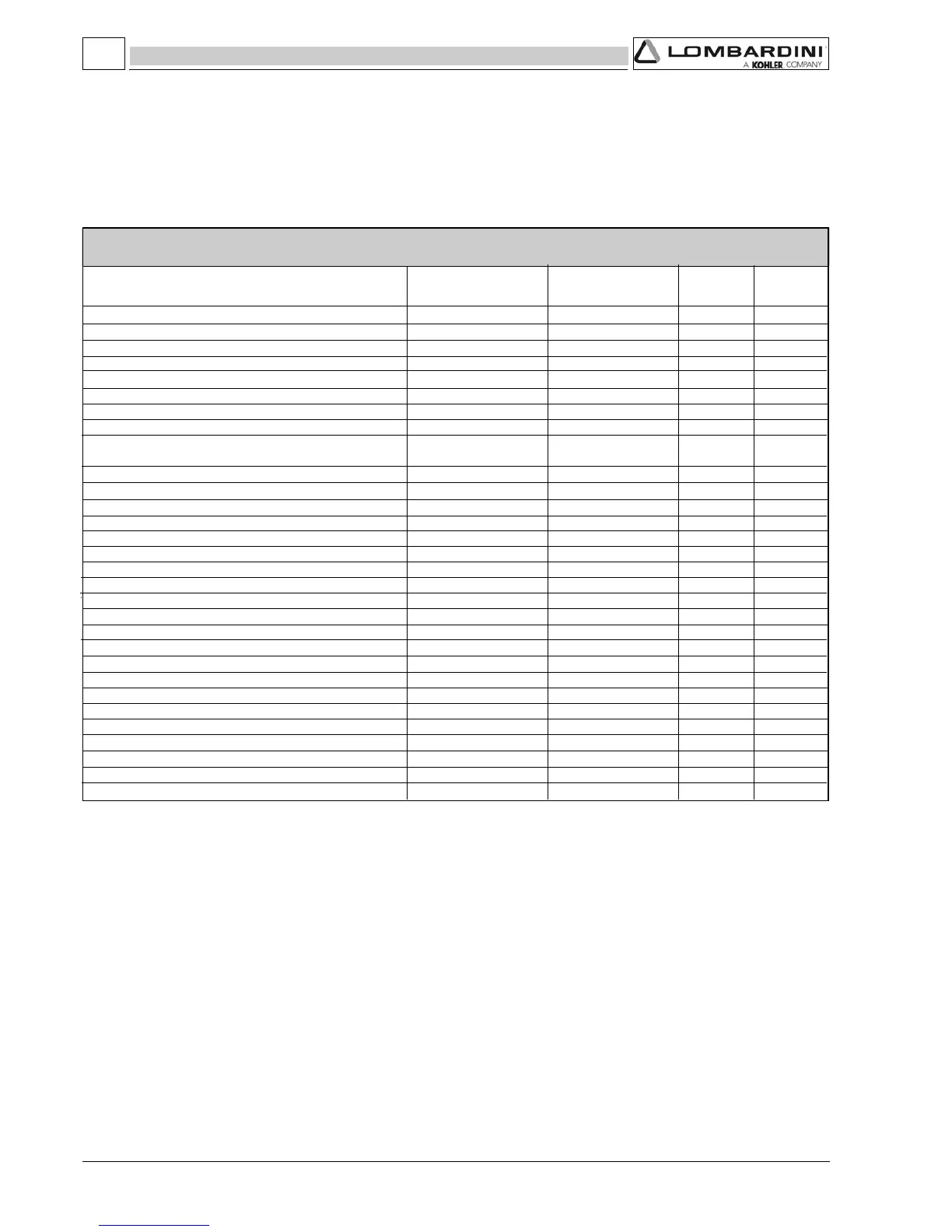

TORQUE SPECIFICATIONS AND USE OF SEALANT

Table of tightening torques for the main components

POSITION

Torque

( Nm )

Diam. & pitch

( mm )

Riference

(figure and page n°)

Sealant

Injection pump control rod

Connecting rod ****

Union for the nozzle (LDW 1204/T)

Glow-plugs

Oil filter cartridge (M 20x1,5 union)

Camshaft bearing (M 6 screws)

Rocker arm cover

Main bearing caps

Oil pan

Camshaft bearing support screw

Glow-plug cable nuts

Fuel lift pump nuts

Belt tensioner nut

External Stop control lever nut

Pump/injector unit fixing nut

Rocker arm assembly support nut

Fuel pump cam

Flywheel side oil seal ring flange

Pre-combustion chamber ring nut

Vacuum pump fixing screws

Belt tensioner

Crankcase

Speed governor lever screw

Driving pulley

Camshaft timing pulley

Oil pressure switch

Oil drain plug

Cylinder headù

Injection pipe

Flywheel

*Tighten the two nuts that fasten each pump/injector unit at the same time. For engines with the injectors fixed with self-

locking nuts, tighten the nuts at 23 Nm.

** Tighten these in two phases: the first phase at 100 Nm, the second phase at 180 Nm. See page 51, figures 95-96.

*** See page 57

**** Aluminium connecting rod with 35 Nm tightening torque.

Loading...

Loading...