Loading...

Loading...

Do you have a question about the Lombardini LDW 502 and is the answer not in the manual?

| Engine Type | Diesel, 4-stroke |

|---|---|

| Number of Cylinders | 2 |

| Fuel System | Indirect injection |

| Starting System | Electric start |

| Lubrication System | Forced lubrication with gear pump |

| Bore x Stroke | 72 mm x 62 mm |

| Cooling System | Air-cooled |

| Displacement | 505 cm³ (30.8 cu in) |

Explains the meaning of symbols used for safety warnings.

Lists critical safety rules for engine operation and general precautions.

Outlines safety procedures to follow during engine operation.

Guides users through diagnosing and resolving engine issues.

Provides detailed technical data and specifications for various engine models.

Outlines the schedule for regular engine servicing and checks.

Specifies the exact types and capacities of lubricants required for the engine.

Details required fuel quality and coolant types, mixtures, and handling.

Illustrates the timing belt and pulley system for correct engine timing.

Details the procedure for safely removing the cylinder head from the engine block.

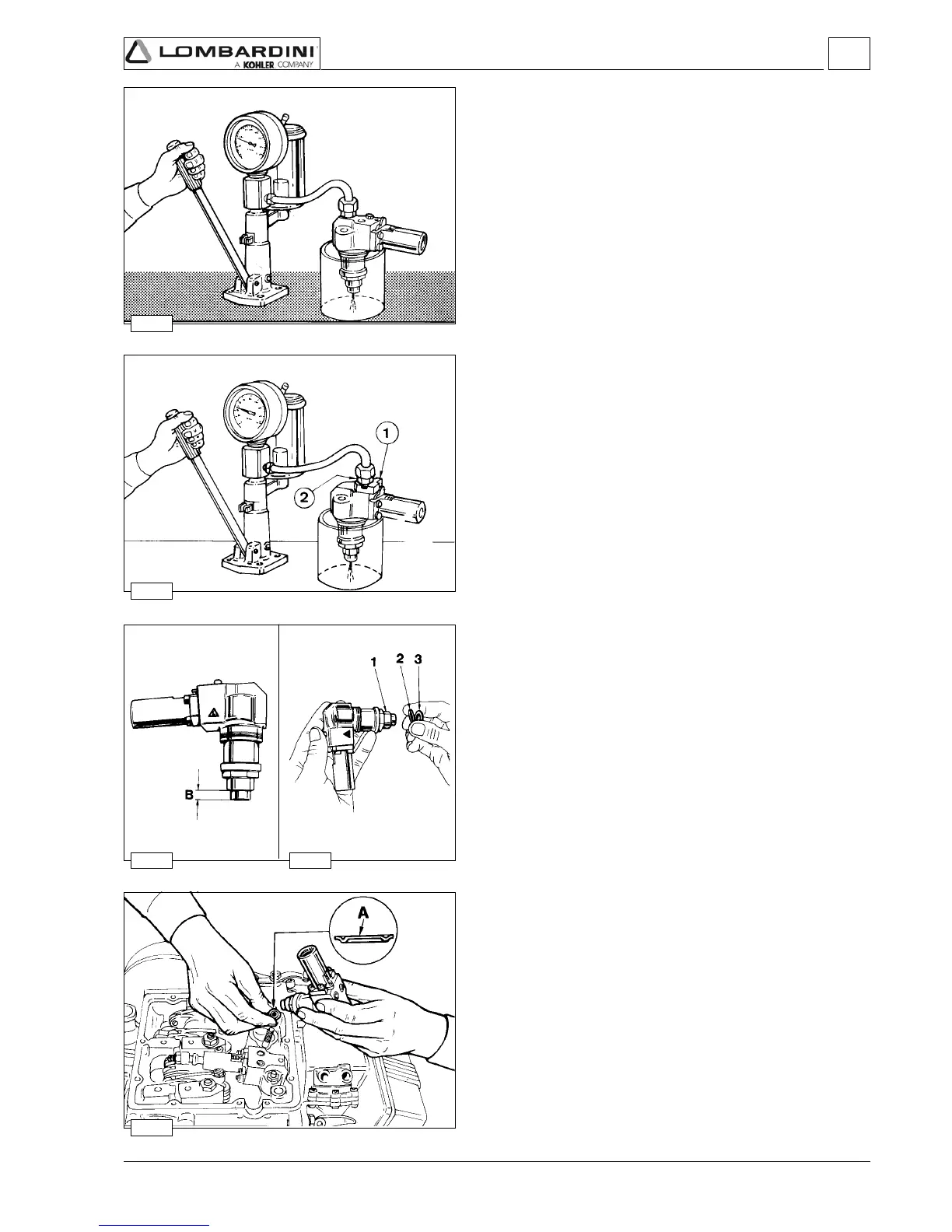

Details the procedure for testing turbocharger pressure for proper function.

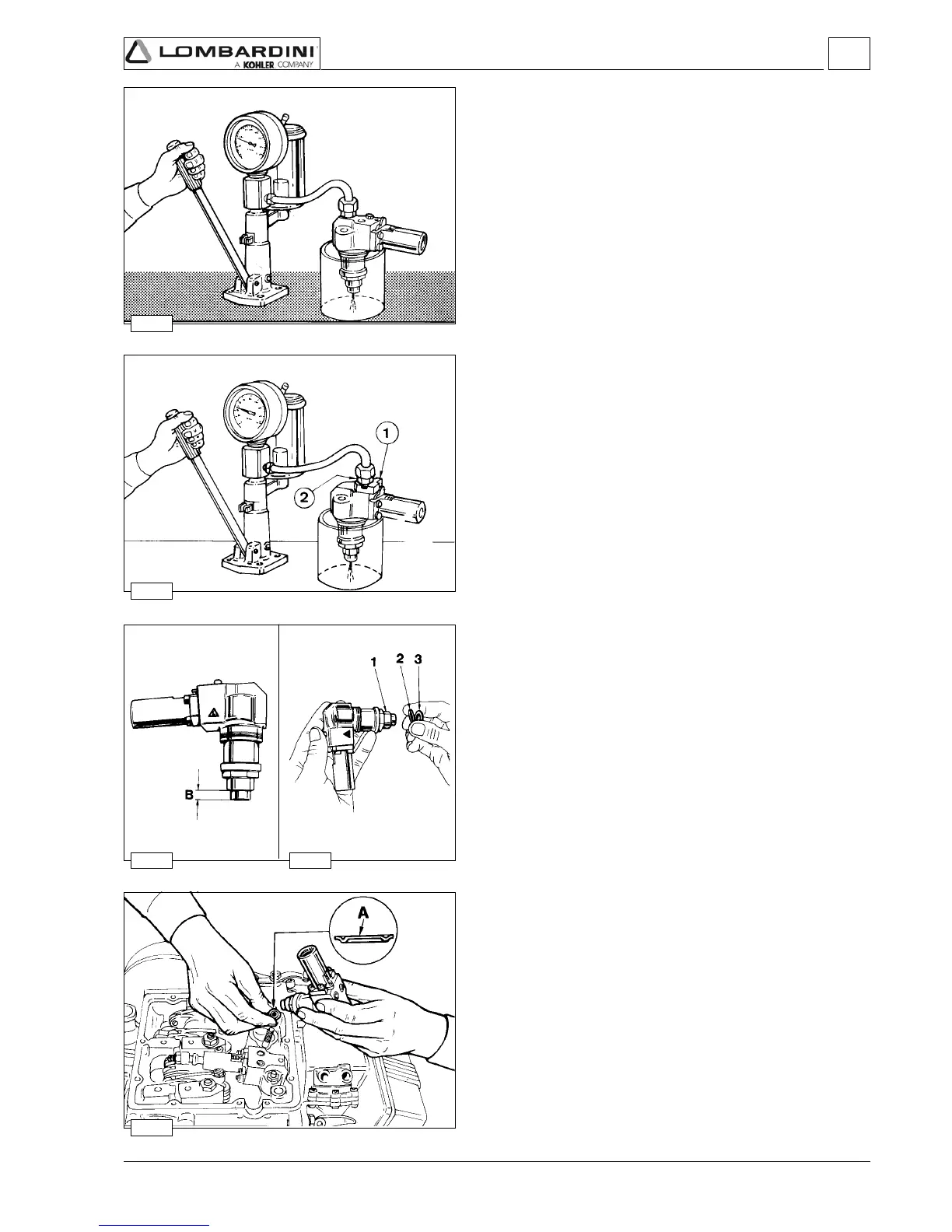

Explains how to adjust the turbocharger's waste gate for optimal performance.

Describes the function and components of the engine's oil pump.