- 80 -

FOCS Workshop Manual_cod. 1.5302.351_7° ed_ rev. 06

αα

α

αα

205WDL

)mm(

T/4021-4021-309-206WDL

)mm(

4041-3001-207WDL

)mm(

°81749.1763.2864.2

°71937.1511.2502.2

°61345.1678.1659.1

°51853.1156.1127.1

°41481.1044.1105.1

°31220.1242.1692.1

°21178.0950.1501.1

°11337.0198.0039.0

°01606.0737.0967.0

°9194.0795.0326.0

°8883.0274.0394.0

°7792.0263.0873.0

°6812.0662.0772.0

182

183

8

αα

α

αα

206-205

4021-309

582-09561-2729992÷0051°01÷°8

206-205

4021-309

582-09561-2720003>°41÷°21

*205703-0956+2720063÷0003°21÷°01

3001-207

4041

092-09564-5329992÷0051°01÷°8

3001-207

4041

092-09564-5320063÷0003°41÷°21

3001-207

4041

092-09564-5320063÷>°51÷°31

T/4021092-09564-5320063÷0051°8÷°6

Injection advance control and regulation

-Dismount the rocker arm cover, see page 40.

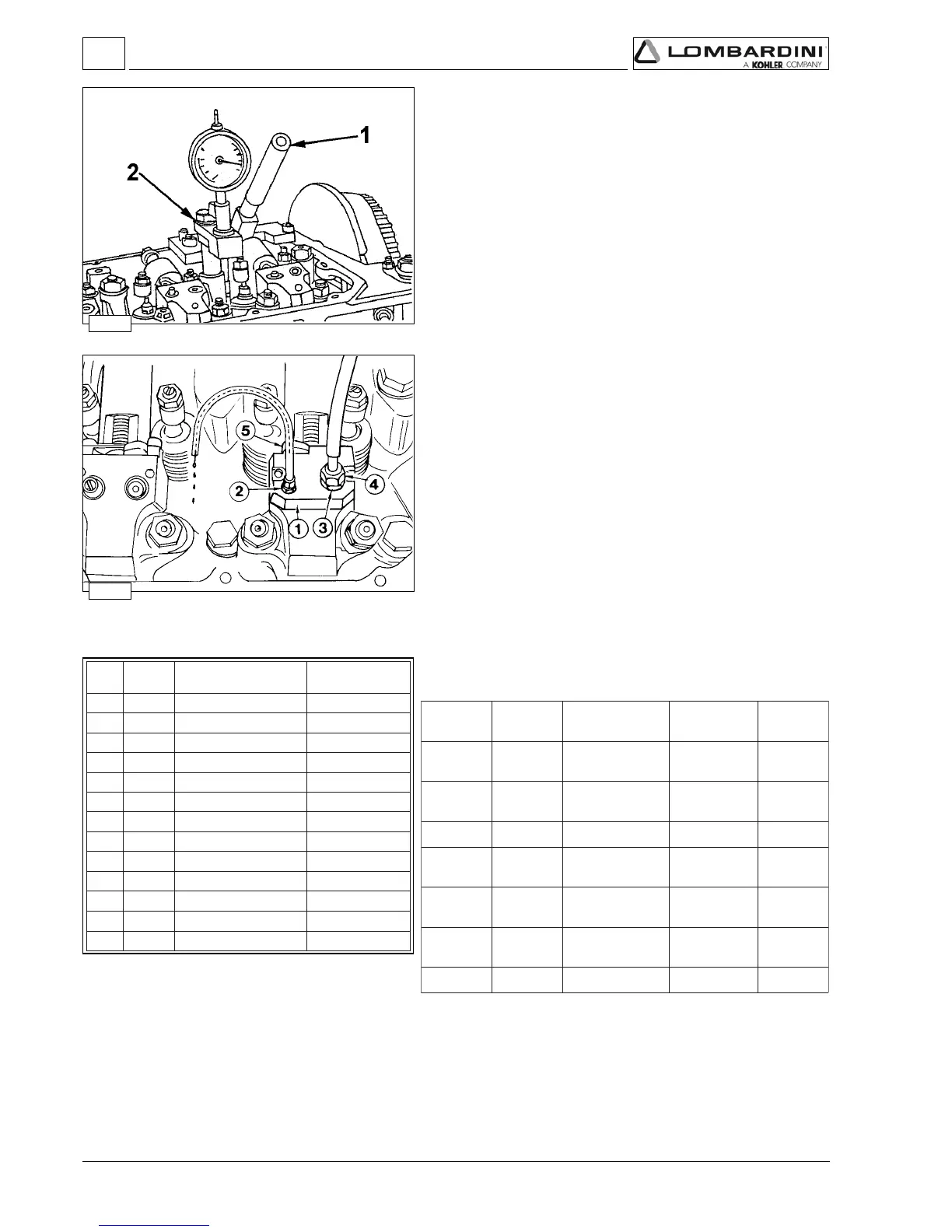

-Position the device on the head, in contact with cylinder no. 1.

-Mount the dial gauge on the valve controlled by tool ref. 1460.048.

-Via lever 1 of the tool, open the valve until it comes into contact

with the piston.

-Then rotate the crankshaft until the TDC is read in the dial gauge.

Then reset the hundredths.

-Remove the fuel pipes.

-Remove the O-ring in contact with the non-return valve and

replace it with the appropriate gasket - equipment component part

ref. 1460.074. Once the check has been completed, remove the

gasket and refit the O-ring.

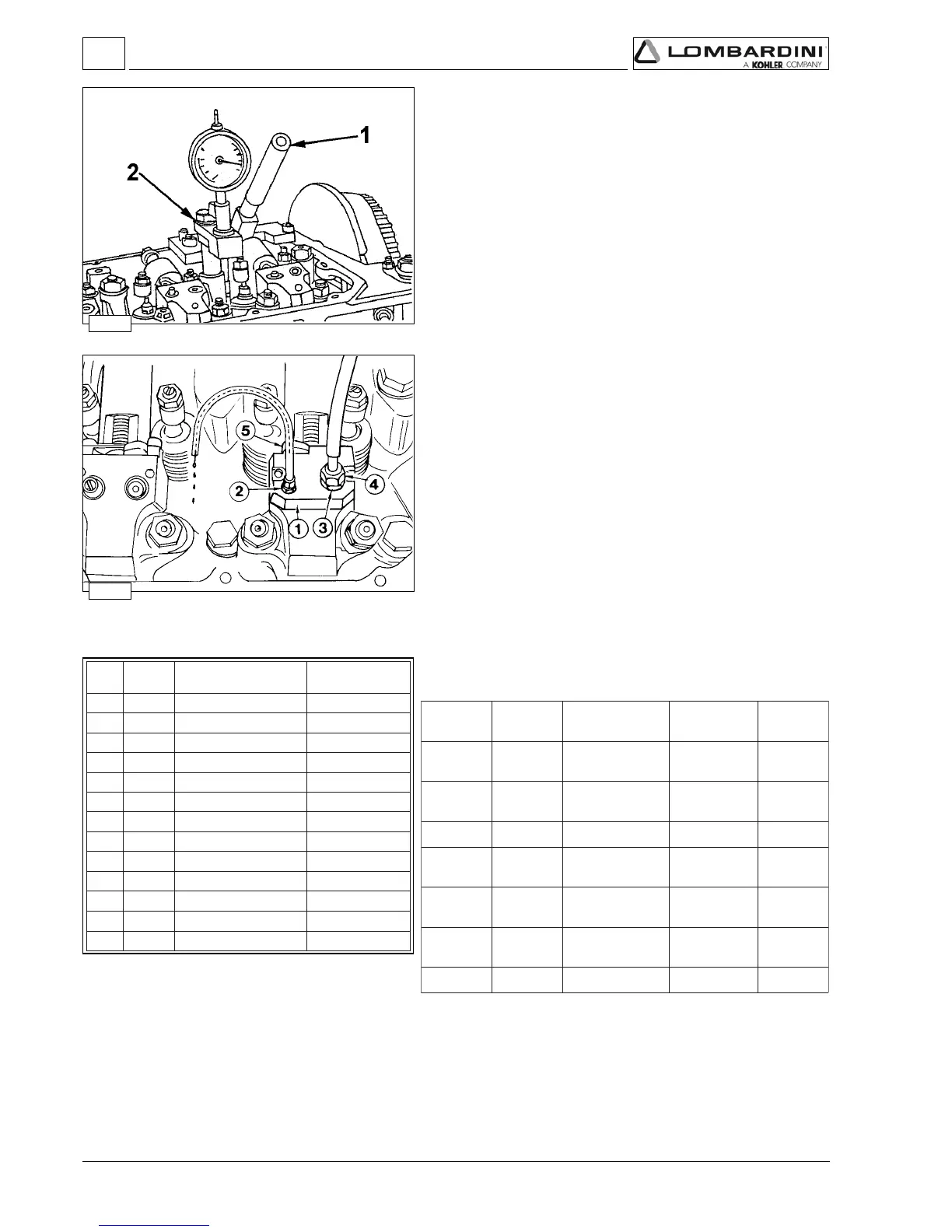

Connect tool 1460.074 on pump n° 1. This will automatically

position the control lever to the maximum delivery. The tool is

provided with 3÷4 couplings for connection to a tank that must be

not lower than 30 cm from the pumps level. Coupling 2 is

equipped with a plastic pipe with internal drip collecting wire.

-Put cylinder 1 under compression and open the tank tap. Fuel

diesel will start to flow out from coupling 2.

-Slowly rotate the engine towards TDC 1 until the diesel fuel stops

leaking out.

-At this point with lever 1 (of fig. 182) move again the valve until it

touches the piston and read on the dial gauge how many

hundredths are missing from the previously reset value (TDC).

-To convert hundredths into degrees, consult the table below.

-Repeat the operation on the other cylinders.

Injection advance for currently used pump/injector unit

* With aluminuim crankcase

Engine Code Reference n° Rpm

Fuel system

Loading...

Loading...