COMPILER TECO/ATL

REG. CODE

1-5302-351

MODEL N°

50563

DATE OF ISSUE

04.90

REVISION 04

ENDORSED

DATE

15.11.99

31

DISASSEMBLY/REASSEMBLY

II

WARNING: Always exercise extreme care when performing engine service work. Refer to and understand the

safety guidelines presented on page 3. Additionally, some engine components have sharp edges which could

cause cuts if not handled properly. Wear hand protection. Further, some engine components are heavy. As such,

wear foot protection to protect from accidental drops of engine components. Always use proper form and

procedures when lifting engine components. Ask for help or assistance if in doubt concerning the lifting or

manipulation of the engine or engine components. The use of compressed air is required for some operations.

Compressed air can be dangerous. Do not direct compressed air towards yourself or others. Do not allow bearings

to spin while drying with compressed air. The use of cleaning solvents is also required for certain service

operations. When “SOLVENT” is recommended, a commercially available, low-toxicity, degreasing solvent such

as “SAFETY-KLEEN” should be used. Wear hand and eye protection and avoid direct contact with solvents.

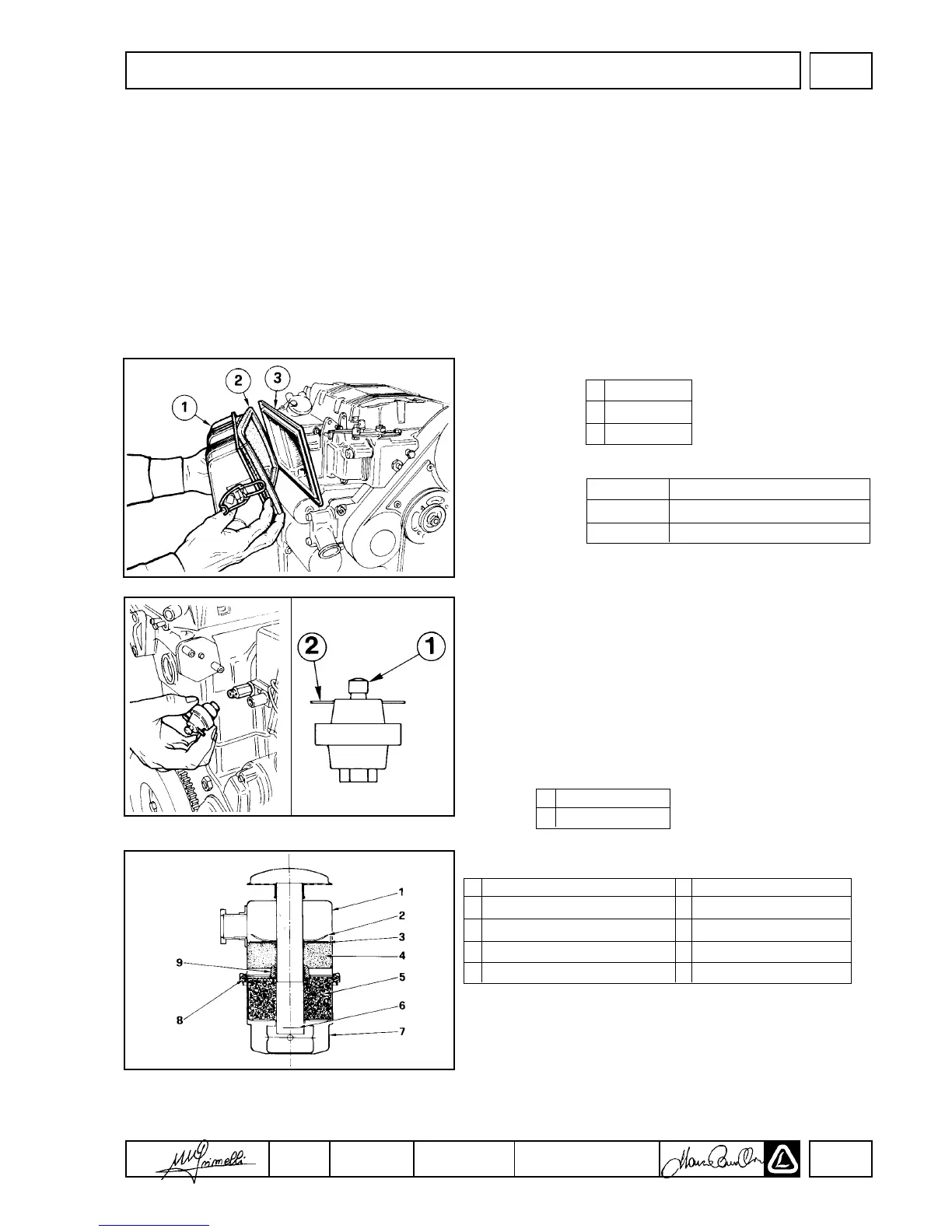

DRY TYPE AIR FILTER- STANDARD ENGINE MOUNTED

Components:

Air Filter Specifications:

INSPECTION: Inspect the air filter cover for cracks, heat damage or warpage.

Replace as required.

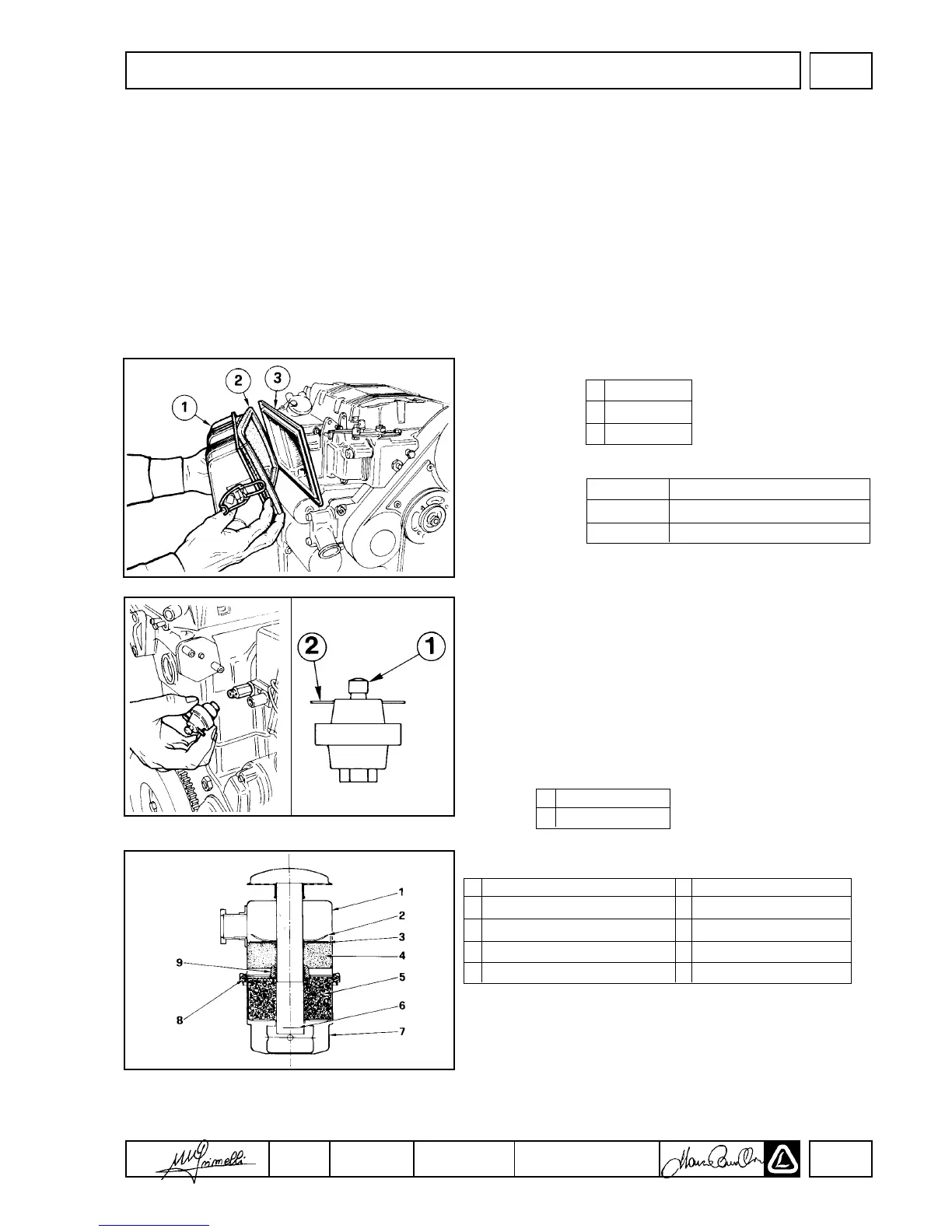

AIR RESTRICTION SWITCH

LDW FOCS diesel engines that are supplied with engine mounted, panel type air

filters as shown above, are fitted with an air filter restriction switch. The purpose of

the air restriction switch is to signal the engine operator, via a lamp or otherwise, of

a high air filter restriction condition. The electrical connections for the signal is

provided at (2) as shown. Following a signal from the restriction switch, the switch

must be reset. Reset the switch by pushing button (1) until the button latches. The

restriction switch is set to 600/650 mm-H

2

O.

After the restriction signal, the air filter should be replaced at once. Do not clean

the air filter element. Operation in a high restriction condition could cause

excessive oil consumption, low power output, engine overheating and potentially

engine damage.

Components:

OIL BATH AIR FILTER

Service Instructions: Check the sealing rings regularly. Replace the sealing rings if

hardening or damage is noted. Inspect the air filter housing and bowl- replace if

damaged. Carefully clean the reservoir bowl and both elements with clean diesel

fuel. Blow the lower element dry with compressed air. Dry the upper element by

squeezing out excess diesel fuel, then drying with suitable cloths. Fill the reservoir

with clean engine oil to the reference mark. DO NOT OVERFILL.

Filtration Level 13-14 micron

Filtration Area 4470 cm

2

- 502, 602, 702, 903, 1003

Filtration Area 7150 cm

2

- 1204, 1404

1 Cover

2 Filter Element

3 Support

1 Reset Button

2 .25” Tab Connection

1 Upper Housing 6 Oil level reference mark (on 7)

2 Diaphragm Seat 7 Reservoir bowl

3 Diaphragm 8 Outer seal ring

4 Polyurethane upper element 9 Inner seal ring

5 Metal wool lower element

Loading...

Loading...