REG. CODE

1-5302-351

MODEL N°

50563

DATE OF ISSUE

04.90

REVISION 04

DATE

15.11.99

ENDORSED

COMPILER TECO/ATI

44

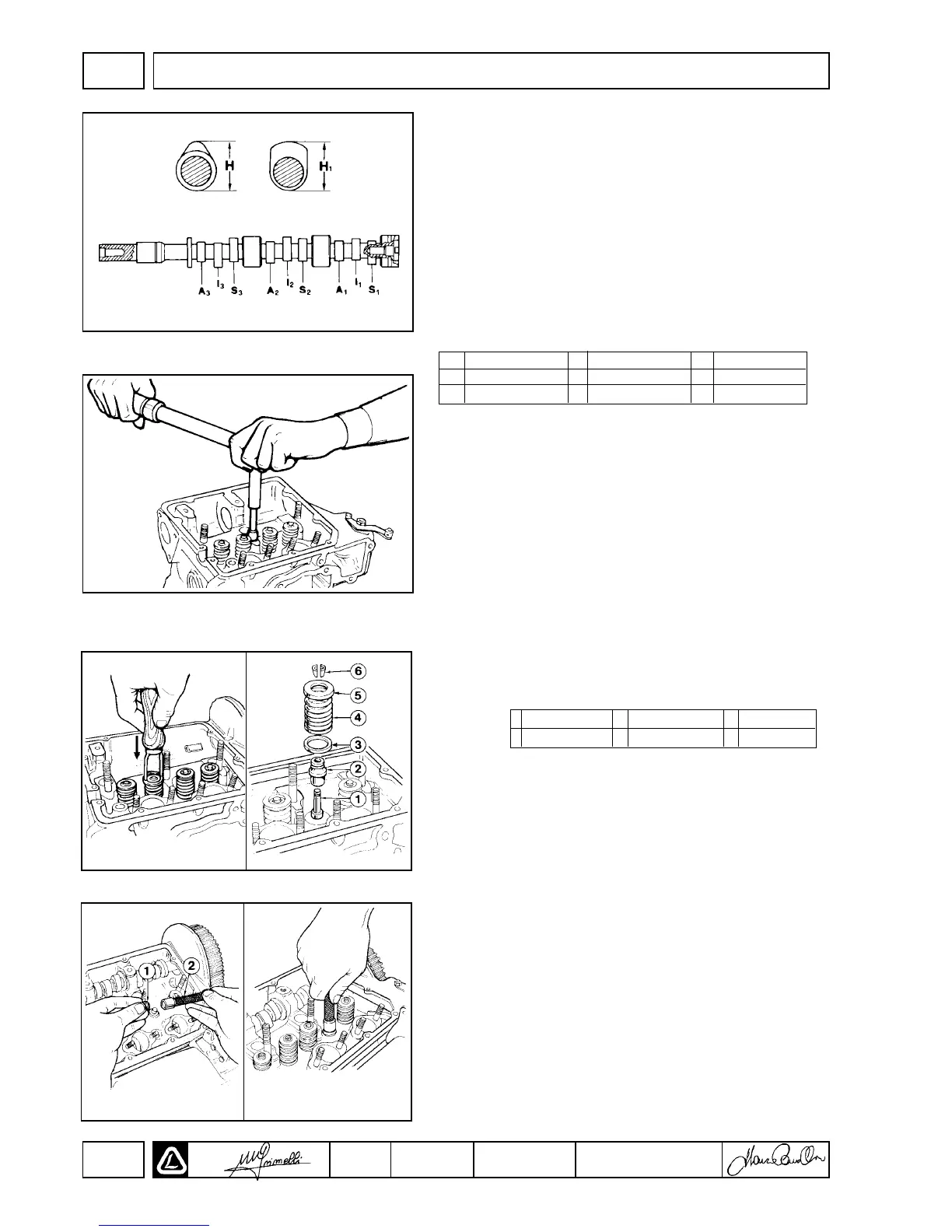

CAMSHAFT LOBE SPECIFICATIONS

NOTE: The camshaft shown in the figure is reflective of a LDW 903.

However, the cam lobes are identical for the LDW 502, LDW 602,

LDW 903 and LDW 1204 diesel engines. The cam lobes are slightly

different for the LDW 1204/T as is shown in the data below.

H- (502, 602, 903, 1204)= Valve Lobe (intake/ exhaust)= 29.598/

29.650mm

H- 1204/T, Intake Lobe= 29.438/29.490mm

H- 1204/T, Exhaust Lobe= 29.778/29.830mm

H- USEABLE Limit (All Models)= Minimum Value minus(-) 0.1mm

H

1

- Injection Lobe (All Models)= 28.948/29.00mm

H

1

- Injection Lobe USEABLE Limit= 28.848mm

LOBE IDENTIFICATION:

CYLINDER HEAD REMOVAL

Remove all cylinder head bolts, then lift the cylinder head from the

crankcase. Do not pry excessively, lever or strike the cylinder head

with a hammer in attempts to break the cylinder head loose from the

head gasket. Do not damage the pre-combustion chambers during

the handling process.

INSPECTION: Thoroughly clean the cylinder head in a non-caustic

solvent. Dry with compressed air. Inspect for cracks and warpage.

Check cylinder head warpage using a high quality straight edge and

precision feeler gauges. Hold the straight edge on the cylinder head

deck and check corner-to-corner and side to side in at least four(4)

equidistant zones. The maximum allowable warpage is 0.10mm. If

warpage exceeds 0.10mm, the cylinder head may be planed a

maximum of 0.20mm. NOTE: Remove pre-combustion chambers

before planing.

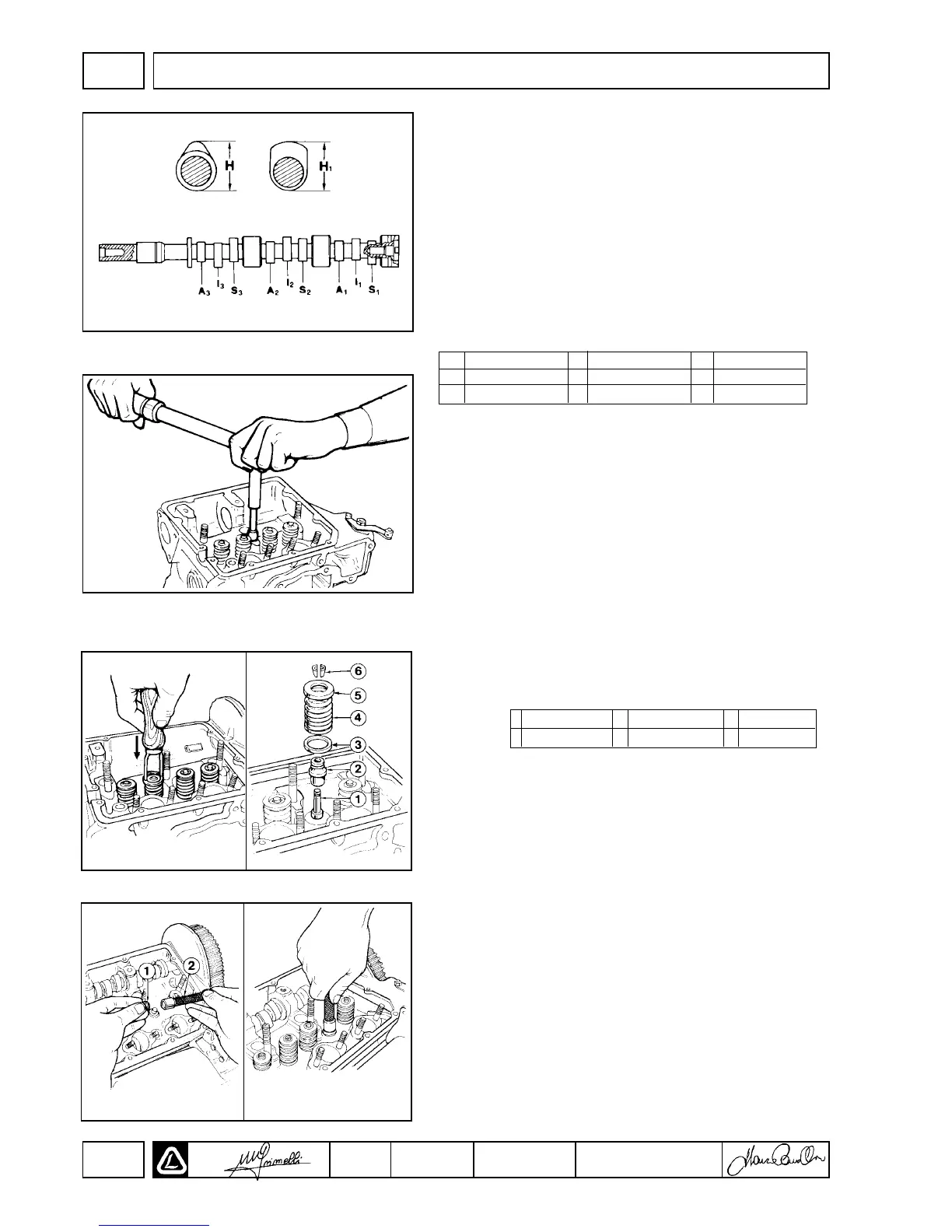

VALVE REMOVAL

Components:

Place the cylinder head on suitable wood spacers so that the pre-

chambers do not touch the top of the work bench when the cylinder

head is oriented as shown. Using a suitable valve spring

compression tool and acting on the spring cap(5), compress the

valve springs so that the collets(6) can be removed while the spring

is being held in the compressed state. WARNING: Valve springs can

store a considerable amount of energy while under compression.

Compress and hold valve springs under compression with care- wear

suitable eye protection. After the collets are removed from all valves,

turn the cylinder head 90° so that the cylinder head is resting on the

intake or exhaust planes. Remove the valves. If valves are to be

reused, label each valve according to cylinder number so that the

valves can be reinstalled in the identical position as removed.

VALVE STEM SEAL INSTALLATION

Following cleaning of the cylinder head and machining or lapping of

the valves/ valve seats, install the valves into the cylinder head.

Using wooden spacers to prevent pre-chamber damage, orient the

cylinder head as shown. Soak new valve stem seals in clean engine

oil for five(5) minutes. Liberally lubricate the valve stems with clean

engine oil. Using special tool 1460-047, place the valve stem seals in

the end of the 1460-047 tool. Carefully push the valve stem onto the

valve stem and over the valve guide. Do not force the seal or use a

hammer to drive the seals into place. The hand force applied must be

parallel to the valve

A1 No. 1 Intake A2 No. 2 Intake A3 No. 3 Intake

S1 No. 1 Exhaust S2 No. 2 Exhaust S3 No. 3 Exhaust

I1 No. 1 Injection I2 No. 2 Injection I3 No. 3 Injection

1 Valve Stem 3 Spring Seat 5 Spring Cap

2 Valve Seal 4 Spring 6 Collets

DISASSEMBLY/REASSEMBLY

II

Loading...

Loading...