COMPILER TECO/ATL

REG. CODE

1-5302-351

MODEL N°

50563

DATE OF ISSUE

04.90

REVISION 04

ENDORSED

DATE

15.11.99

57

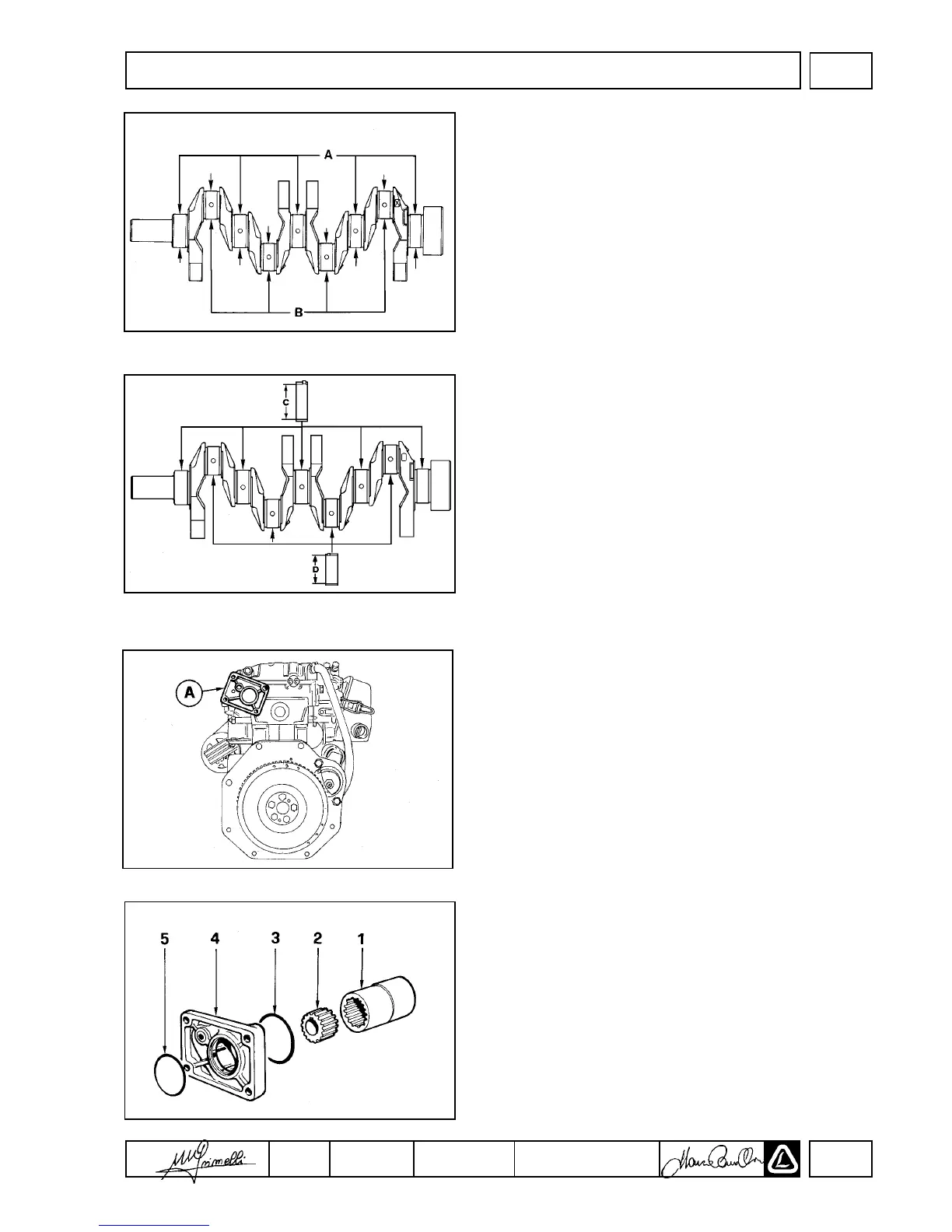

CRANKSHAFT JOURNAL SPECIFICATIONS

For LDW 502,602,903,1204,1204/T

A = Main Journals= 47.984 / 48.000mm (WEAR Limit = 47.900mm)

For LDW 702,1003,1404

A = Main Journals= 50,981 / 51.000mm (WEAR Limit = 50.900mm)

For LDW 502,602,702,903,1003,1204,1204/T,1404

B = Rod Journals = 39.984 / 40.000mm (WEAR Limit = 39.900mm)

NOTE 2: THE CRANKSHAFTS IN THE ALUMINUM AND CAST

IRON VERSIONS OF THE LDW 502 ARE NOT

INTERCHANGEABLE.

UNDERSIZED BEARINGS- ROD and MAIN

Undersized connecting rod and main bearings are available in sizes

0.25 and 0.50mm. Use of the undersized bearings will require the

nominal size of the rod/ main journals to be reduced by 0.25 or

0.50mm respectively.

MAIN and CONNECTING ROD BEARINGS

The dimensions shown reflect clean, installed and torqued bearing

inserts.

For LDW 502,602,903,1204,1204/T

C = Main Bearings =47.984 / 48.016mm (WEAR Limit = 48.055mm)

C-A = 0.022 / 0.074mm (WEAR Limit = 0.200mm)

For LDW 702,1003,1404

C = Main Bearings =51,023 / 51,059mm (WEAR Limit = 51,098mm)

C-A = 0.023 / 0.078mm (WEAR Limit = 0.200mm)

For LDW 502,602,702,903,1003,1204,1204/T,1404

D = Rod Bearings =40.021 / 40.050mm (WEAR Limit = 40.100mm)

D-B = 0.021 / 0.066mm (WEAR Limit = 0.130mm)

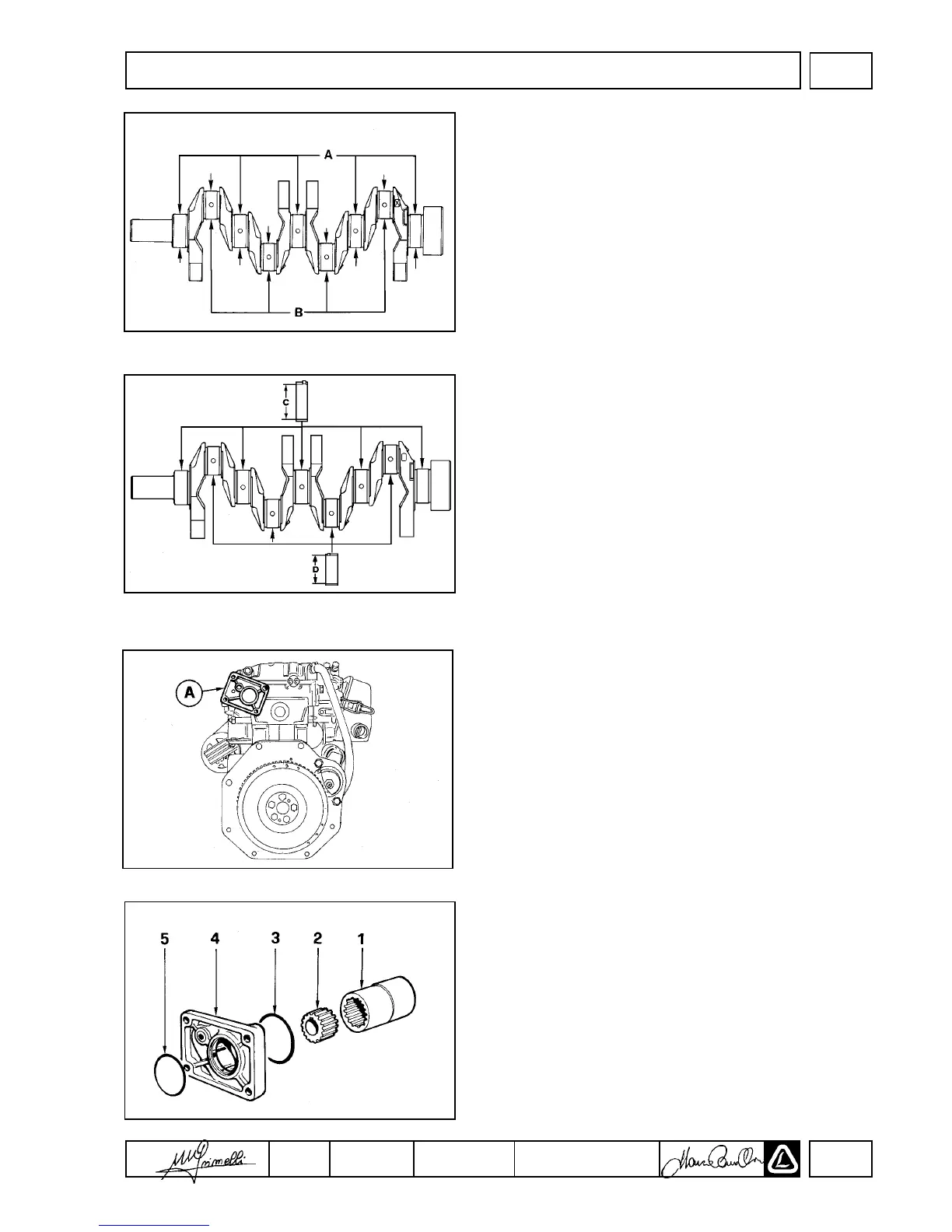

HYDRAULIC PUMP PTO- (No. 3 PTO)

All FOCS diesel engines may be fitted with a hydraulic pump

drive(A) as shown. The hydraulic drive takes power from the back of

the engine camshaft.

Hydraulic pump adaptations for DIN size 2PD, DIN size 1P and

BOSCH pumps are available.

DRIVE SPECIFICATIONS:

Speed Ratio: 1 : 2, or 1/2 engine speed.

Maximum Torque = 37 Nm, irrespective of engine speed.

NOTE: 37 Nm @ 3600 r/min corresponds to 7 kW.

HYDRAULIC DRIVE COMPONENTS- No. 3 PTO

1 Splined Drive- (Bolts to Camshaft)

2 Pump Drive Gear (Attaches to Pump Input Shaft)

3 O-Ring

4 Pump Support (Bolts to Cylinder Head)

5 O-Ring

The splined drive(1) also includes the eccentric for the fuel lift pump.

The splined drive must be bolted to the camshaft end and torqued to

80 Nm. The pump drive gear(2) must be torqued to the hydraulic

pump input shaft. Check with the pump manufacturer for torque

specifications at the input shaft.

DISASSEMBLY/REASSEMBLY

II

Loading...

Loading...