REG. CODE

1-5302-351

MODEL N°

50563

DATE OF ISSUE

04.90

REVISION 04

DATE

15.11.99

ENDORSED

COMPILER TECO/ATI

64

COOLING SYSTEM

V

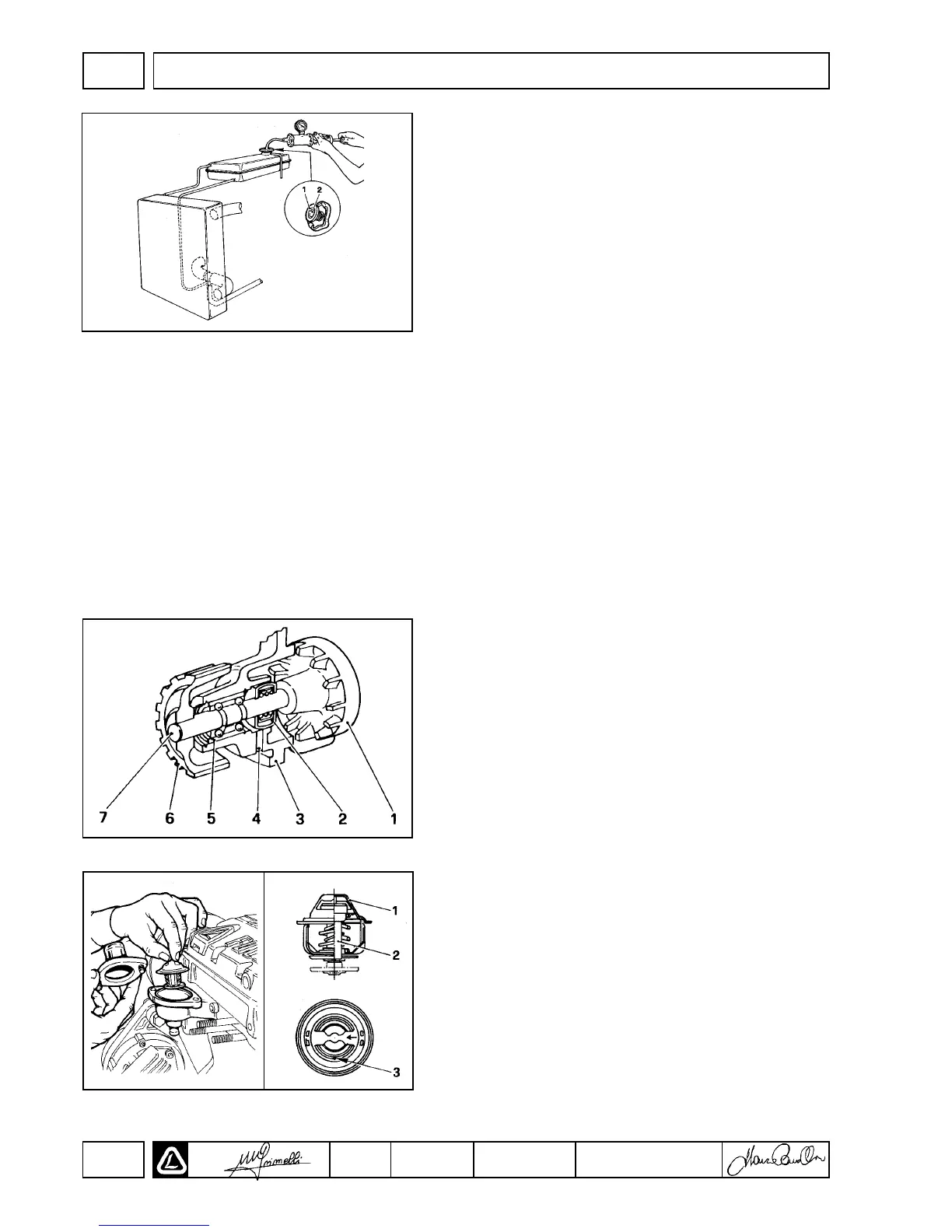

COOLING SYSTEM PRESSURE CHECK / RADIATOR CAP

INSPECTION

Pressure checking the cooling system is the only reliable method of

determining the source of coolant leaks and the condition of the

radiator, hoses and coolant pump seals. The radiator cap controls

operating cooling system pressure and thus must be inspected

regularly. The illustration shown depicts a cross flow type radiator

with a remote expansion tank. The proceedures / inspection criterion

below is applicable to both cross flow and top tank radiators.

Radiator Cap: Inspect the vacuum valve (1) and the relief valve (2).

Fit the radiator cap onto a suitable radiator cap testing fixture.

Pressurize to 0.7 bar to insure the radiator cap holds rated pressure.

Replace the cap if 0.7 bar cannot be reached before pressure relief.

Replace the radiator cap if any degradation is seen on the vacuum

valve seal or the pressure relief seal or if the cap is bent, deformed or

damaged.

Radiator Seat: The sealing ability of the radiator cap is a function of

the radiator or expansion tank seat. Inspect the radiator cap seat and

replace/ repair as needed.

Cooling System Pressure Test: Fill the cooling system completely

with a 50/50% solution- water/ ethylene glycol. Fit a cooling system

pressurizing device to the cooling system fill port. Pressurize the

cooling system to 0.7 bar. The pressure should hold steady. If the

pressure does not hold steady at 0.7 bar, a malfunction in the

pressure device exists or a leak in the cooling system exists. Inspect

the cooling system for signs of liquid at all joints, hoses and at the

coolant pump. Tighten, repair or replace as required.

NOTE: Lombardini recommends a radiator cap pressure relief setting

of 0.7 bar. Do not operate the engine with a pressure cap of higher or

lower setting installed.

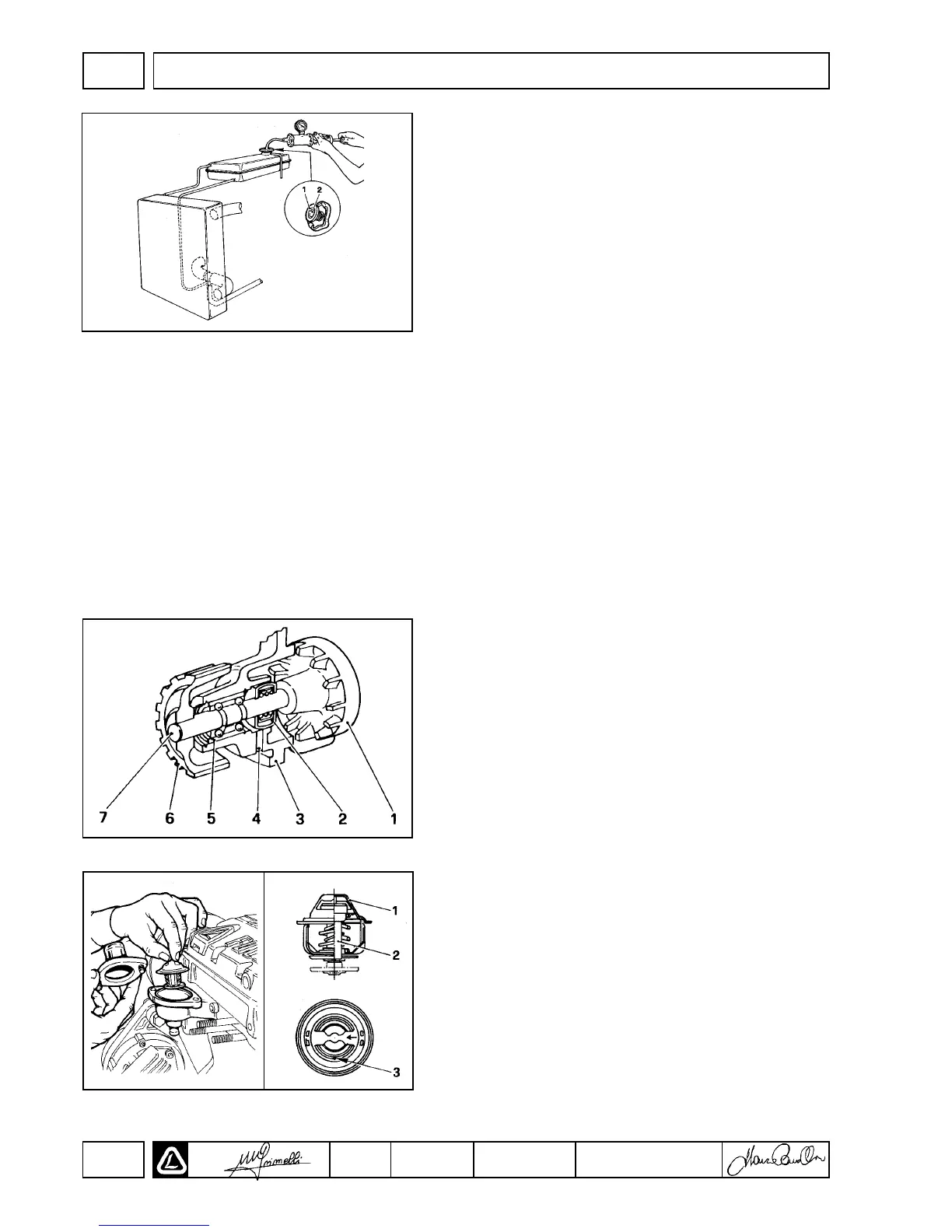

COOLANT PUMP DETAILS

The design of all LDW-FOCS coolant pumps is similiar. However, the

impeller(1) size and seal assembly (2) are larger for the LDW 1204

,LDW 1204/T and 1404, allowing for greater coolant flow.

Components:

1 Impeller

2 Seal assembly

3 Pump body

4 Weep hole

5 Bearing

6 Pulley

7 Shaft

THERMOSTAT

Removal: Drain the engine coolant in a suitable container. Remove

the two(2) capcrews retaining the coolant outlet to the thermostat

housing. Remove the thermostat from the thermostat housing.

Inspection: Inspect the the thermostat for deposits, corrosion and

deformation. Clean or replace as required.

Components:

1 Thermostat body- stainless steel, brass or thermoplastic.

2 Expansion bulb

3 Bleed vent

NOTE: Metalic thermostats require a O-ring gasket- replace as

required.

Loading...

Loading...