COMPILER TECO/ATL

REG. CODE

1-5302-351

MODEL N°

50563

DATE OF ISSUE

04.90

REVISION 04

ENDORSED

DATE

15.11.99

73

FUEL SYSTEM

VI

UNIT INJECTOR DELIVERY EQUALIZATION- PREPARATION

Due to the fact that unit injectors are both injection pump and injector, all unit

injectors within a FOCS diesel engine must be equalized to facilitate the

identical delivery of fuel within individual cylinders. The equalization procedure

is a operational test with the valve cover removed. Therefore, proper eye

protection must be worn and great care must be taken to insure no body or

clothing contact with rotating engine components.

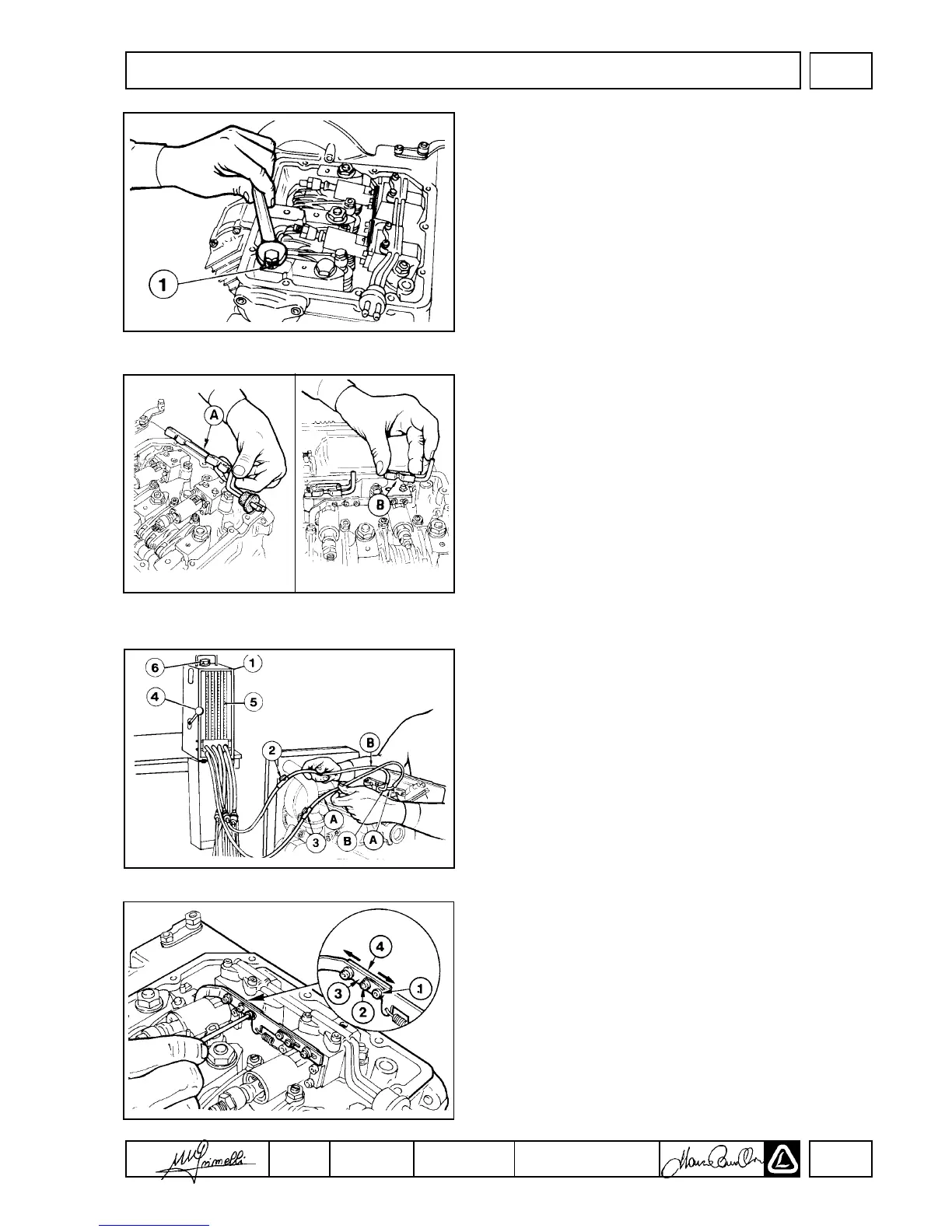

After carefully removing the engine valve cover, install a M8x1.25x10mm

capscrew and 8mm copper gasket at position(1) as shown. Failure to install

the bolt as shown will result in a large scale oil spill and loss of oil pressure to

the engine during the operational procedure presented below.

NOTE: SEE PAGE 74 FOR INITIAL INJECTOR CONTROL RACK AND

GOVERNOR ADJUSTMENT PROCEDURES.

UNIT INJECTOR DELIVERY EQUALIZATION- PREPARATION (cont.)

Remove the fuel manifold assembly(A). In place of the fuel manifold, install

on each unit injector a test head(B). The test heads are supplied as part of

the equalization tool package. Please note that early versions of the unit

injector and late versions of the unit injector require different test heads.

Please refer to page 56 for further details.

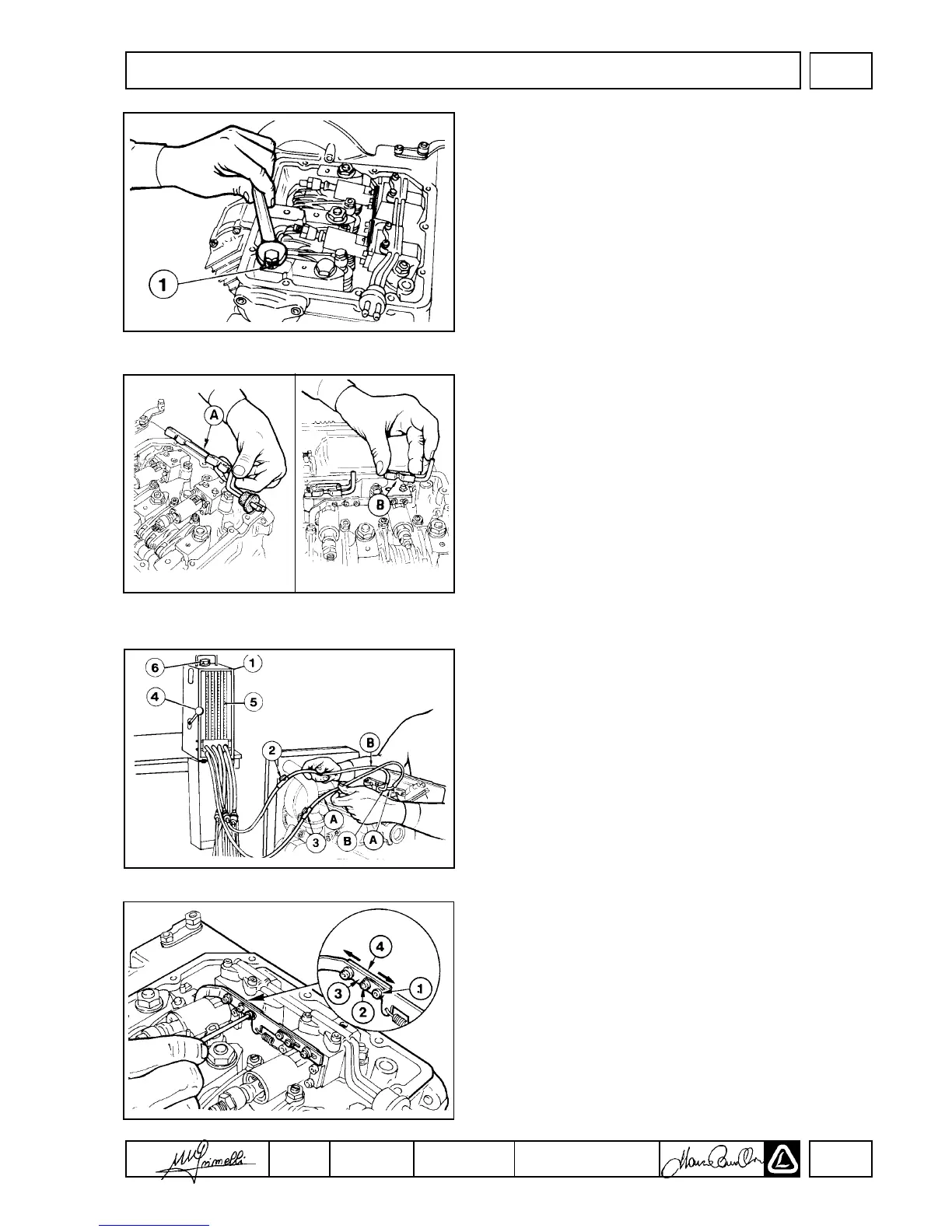

EQUALIZATION TOOL INSTALLATION, PLUMBING

Place the equalization tool on a stable surface , with the base of the

equalization tool at least 20cm higher than the level of the unit injectors.

Close all valves(2,3). Remove fuel cap(6) and fill the reservoir with clean

diesel fuel. With reference to the diagram, connect the lower hoses

(A)coming from the equalization fixture to the test head position(A). The

hoses should be connected to the test heads in a logical manner. That is, the

left most hose should be connected to No. 1 unit injector (flywheel side), then

subsequent hoses from left to right, connected to cylinders 2, 3, 4 as

required. Connect the upper hoses(B) to the test head position (B). Make

sure that the control lever(4) is in the upper position.

After completion of the hose routing/ plumbing, open the valves (2,3). Start

the engine and allow to idle. Increase and lock the engine speed to 1500 rpm.

Once the engine operates smoothly and the 1500rpm is reconfirmed, pull the

control lever(4) downward for approximately one(1) minute. While closely

watching the fuel level in the cylinder tubes(5), note the rate at which fuel is

consumed. NOTE:, the control lever(4) must be returned to the upper

position prior to fuel depletion in the tubes(5).

During operation with the control lever down, determine the cylinder(s) which

are consuming more fuel as indicated by the speed at which the fuel is

depleted from each individual tube(5). Delivery rates in each cylinder should

be within 2 cm

3

during one(1) minute of operation. Reduce the fuel delivery

rate to the cylinder(s) consuming the most fuel. Delivery may be adjusted as

follows:

FUEL RATE ADJUSTMENT DETAILS

To increase the fuel delivery of an individual unit injector, the injector rack

must be moved slightly toward the flywheel end of the engine. With reference

to the figure on the left, loosen screws (1) and (2) 1/2 turn. Increase the

cylinder fuel delivery by moving plate (4) slightly towards the flywheel, thus

changing the relative position of control rod (3). Reductions in fuel delivery

can be facilitated by moving the plate away from the flywheel. After

adjustment, torque screws (1) and (2) to 1.1 Nm.

Repeat the equalization test until the individual cylinder fuel consumptions are

within 2 cm

3

during a one(1) minute period.

NOTE: The equalization procedure should be performed following an injector

re

Loading...

Loading...