28 ENGLISH

7. Gently lower the handle to the fully lowered posi-

tion while applying pressure in parallel with the circular

saw blade and push the carriage toward the guide

fences to cut the workpiece.

8.

wait until

the circular saw blade has come to a complete stop before

returning the circular saw blade to its fully elevated position.

Fig.48

Compound cutting

Compound cutting is the process in which a bevel

angle is made at the same time in which a miter angle

is being cut on a workpiece. Compound cutting can be

performed at the angle shown in the table.

Miter angle Bevel angle

Left and Right 0° - 45° Left and Right 0° - 45°

When performing compound cutting, refer to the section for

press cutting, slide (push) cutting, miter cutting, and bevel cut.

Cutting crown and cove moldings

Crown and cove moldings can be cut on a compound

There are two common types of crown moldings and one type

of cove moldings; 52/38° wall angle crown molding, 45° wall

angle crown molding and 45° wall angle cove molding.

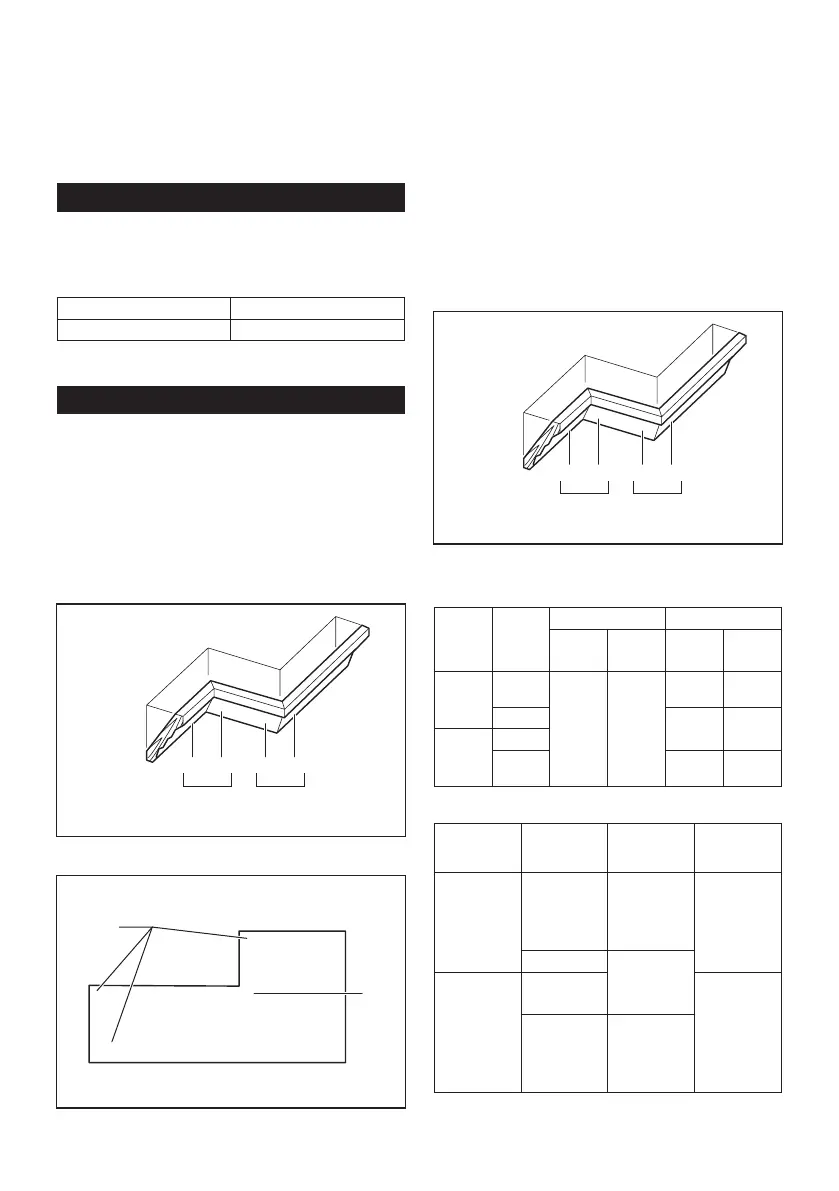

Fig.49: 1. 52/38° type crown molding 2. 45° type

crown molding 3. 45° type cove molding

(a) (b) (c) (d)

12

1. Inside corner 2. Outside corner

2

(a)

(b)

(a)

(b)

(b)

(a)

(b)

(a)

(a)

(b)

(c)

(d)

1

1. Inside corner 2. Outside corner

Measuring

workpiece according to it. Always make sure that width

of the workpiece's wall contact edge is the same as wall

length.

Fig.50: 1. Workpiece 2. Wall width 3. Width of the

workpiece 4. Wall contact edge

Always use several pieces for test cuts to check the

saw angles.

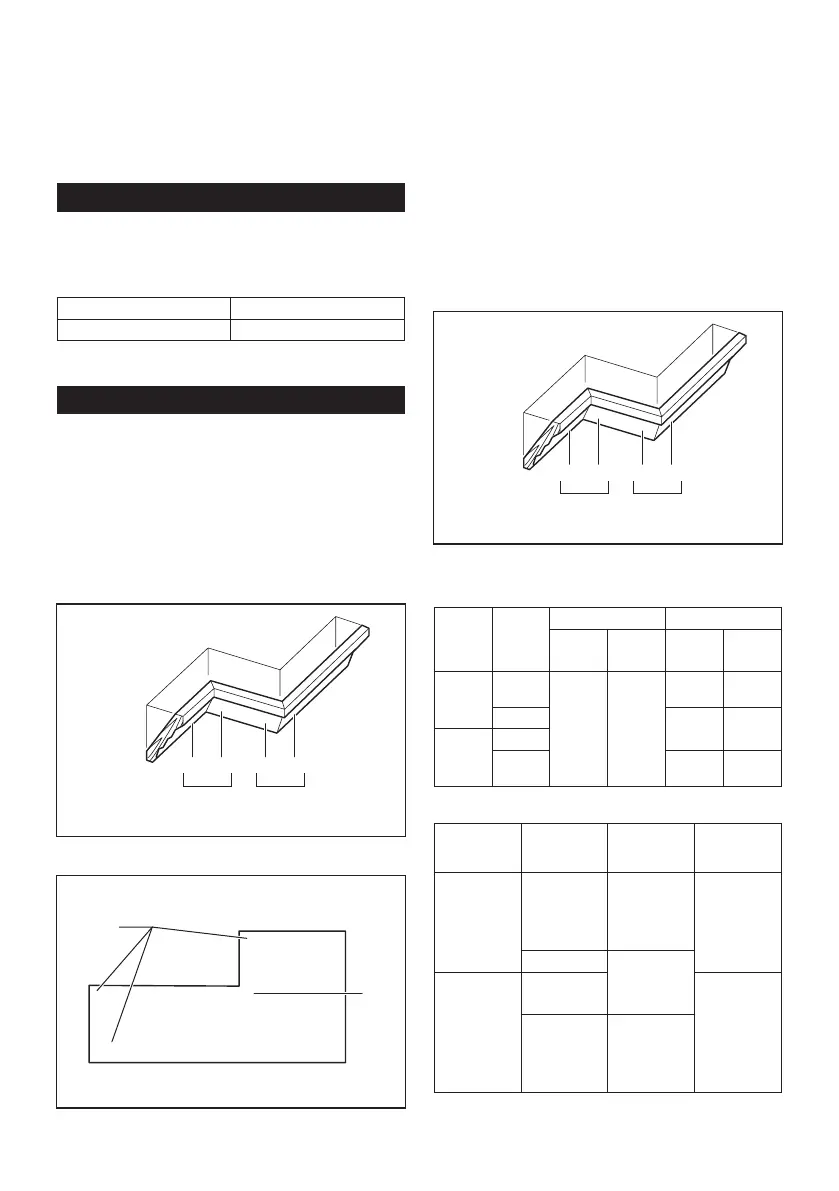

When cutting crown and cove moldings, set the bevel

angle and miter angle as indicated in the table (A) and

position the moldings on the top surface of the saw

base as indicated in the table (B).

In the case of left bevel cut

(a) (b) (c) (d)

12

1. Inside corner 2. Outside corner

Table (A)

– Molding

position

in the

Bevel angle Miter angle

52/38°

type

45° type 52/38°

type

45° type

For

inside

corner

(a) Left

33.9°

Left 30° Right

31.6°

Right

35.3°

(b) Left

31.6°

Left

35.3°

For

outside

corner

(c)

(d) Right

31.6°

Right

35.3°

Table (B)

– Molding

position in

Molding

edge against

guide fence

Finished

piece

For inside

corner

(a) Ceiling

contact edge

should be

against guide

fence.

Finished

piece will be

on the Left

side of blade.

(b) Wall contact

edge should

be against

guide fence.

For outside

corner

(c) Finished

piece will be

on the Right

side of blade.(d) Ceiling

contact edge

should be

against guide

fence.

Loading...

Loading...