Valve actuating gear

Drive of the push rod for the inlet and exhaust

valves is from the camshaft via inlet and exhaust

rocking levers supported on a joint pillow, with the

cam movements being transmitted via a follower.

The push rod movement is in the cylinder head

transmitted to short rockers, and from these to a

guided, spring-loaded yoke. This yoke operates two

equal valves each.

The pillow supporting the rocking levers (the rocking

lever casing) is bolted to the cylinder head.

Bearing bushes, ball pans and yokes are lubricated

by means of a fitting in the pillow.

Fuel injection system

The engine is provided with one fuel injection pump

unit, an injection valve, and a high pressure pipe for

each cylinder.

The injection pump unit is mounted on the engine

frame. The pump unit consists of a pump housing

embracing a roller guide, a centrally placed pump

barrel and a plunger. The pump is activated by the

fuel cam, and the volume injected is controlled by

turning the plunger.

The fuel injection valve is located in a valve sleeve in

the centre of the cylinder head. The opening of the

valve is controlled by the fuel oil pressure, and the

valve is closed by a spring.

The high pressure pipe which is led through a bore

in the cylinder head is surrounded by a shielding

tube.

The shielding tube also acts as a drain channel in

order to ensure any leakage from the fuel valve and

the high pressure pipe will be drained off.

The complete injection equipment including injec-

tion pumps and high pressure pipes is well

enclosed behind removable covers.

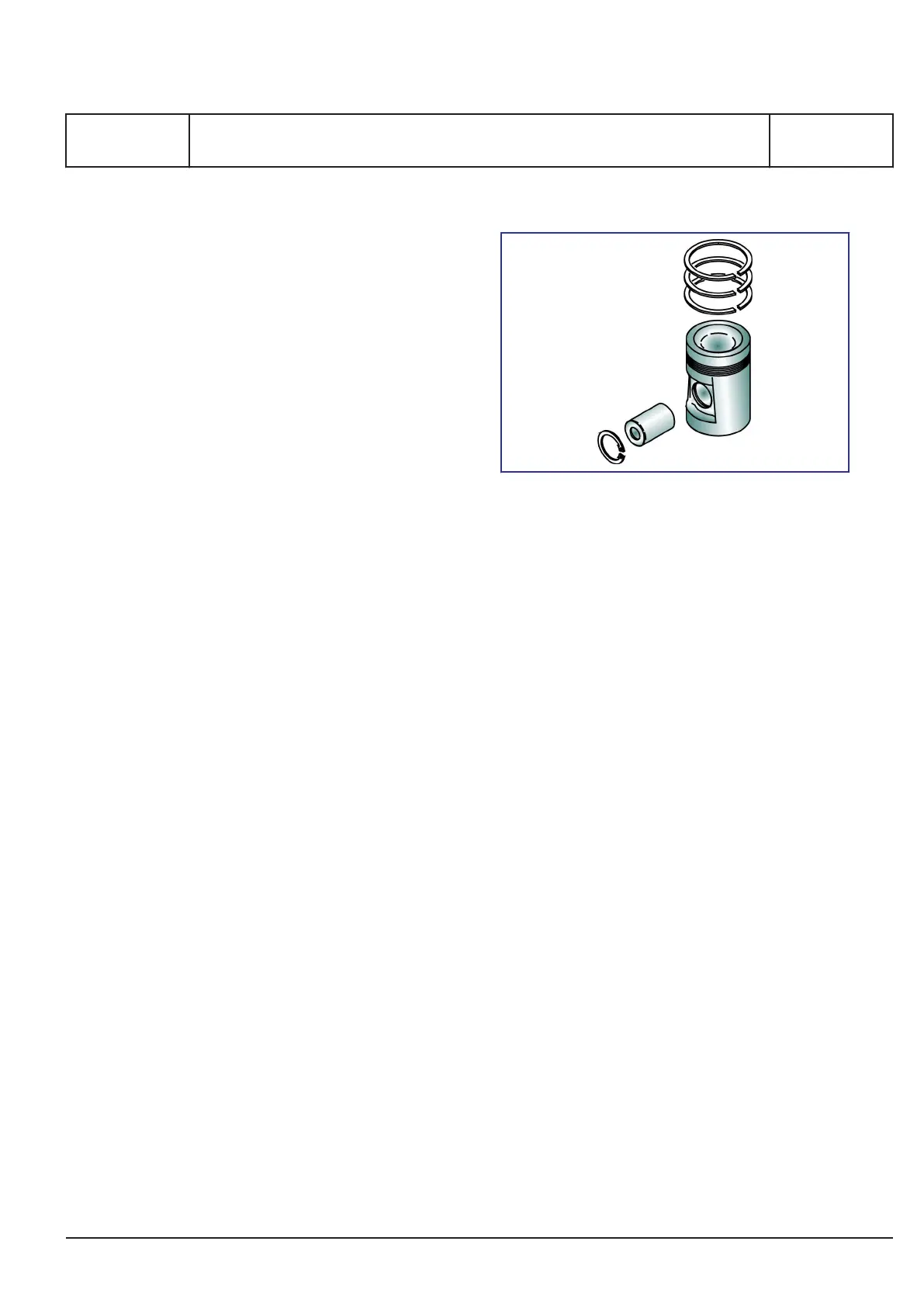

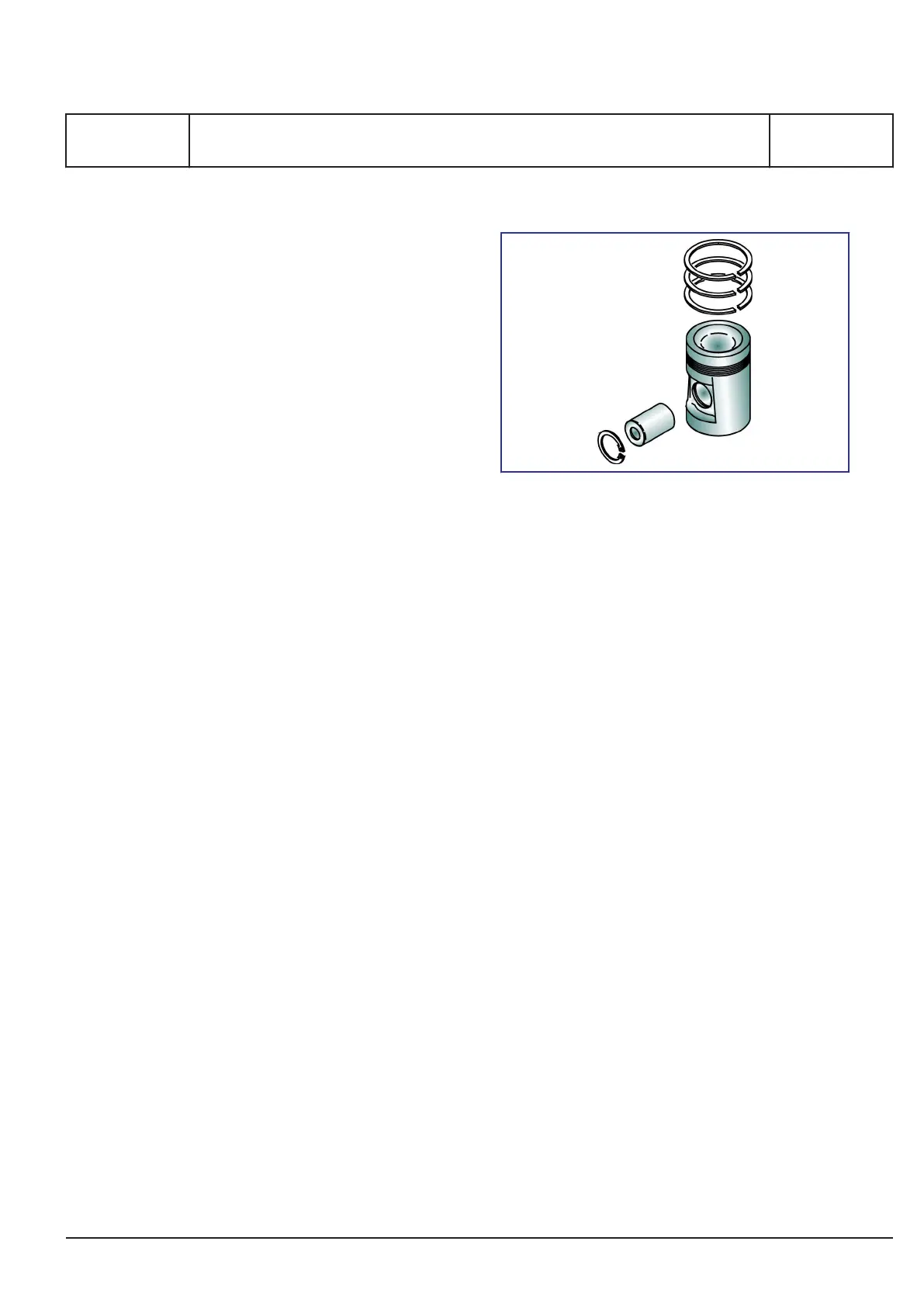

Piston

The piston, which is oil-cooled and of the compo-

site type, has a body made of nodular cast iron and

a crown made of forged deformation resistant steel.

It is fitted with 2 compression rings and 1 oil scraper

ring in hardened ring grooves.

Figure 4: Piston

By the use of compression rings with different bar-

relshaped profiles and chrome-plated running surfa-

ces, the piston ring pack is optimized for maximum

sealing effect and minimum wear rate.

The piston has a cooling oil space close to the pis-

ton crown and the piston ring zone. The heat trans-

fer, and thus the cooling effect, is based on the

shaker effect arising during the piston movement.

The cooling medium is oil from the engine's lubri-

cating oil system.

Oil is supplied to the cooling oil space through

channels from the oil grooves in the piston pin

bosses. Oil is drained from the cooling oil space

through ducts situated diametrically to the inlet

channels.

The piston pin is fully floating and kept in position in

the axial direction by two circlips.

Connecting rod

The connecting rod is of the marine head type.

The joint is above the connecting rod bearing. This

means that the big-end bearing must not be

opened when pulling the piston. This is of advant-

age for the operational safety (no positional

changes/no new adaption), and this solution also

reduces the height dimension required for piston

assembly / removal.

Connecting rod and bearing body consist of CrMo

steel. They are die-forged products.

The bearing shells are identical to those of the

crankshaft bearing. Thin-walled bearing shells hav-

ing an AISn running layer are used.

MAN Diesel & Turbo

1689477-8.1

Page 3 (7)

General description

B 10 01 1

L27/38S, L27/38

2015.11.26

Loading...

Loading...