STRUCTURALS 5540F/YB5515 SERVICE MANUAL

11-56

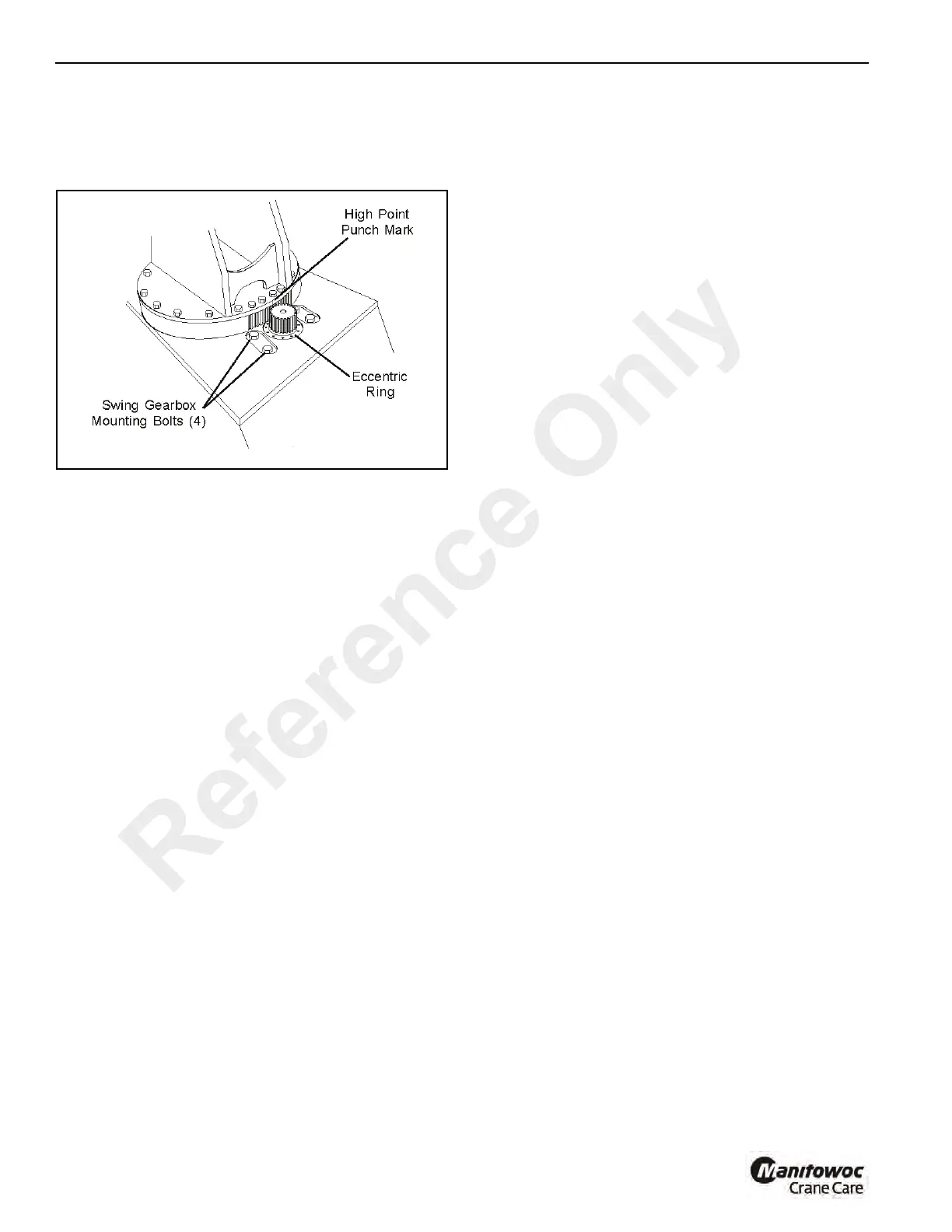

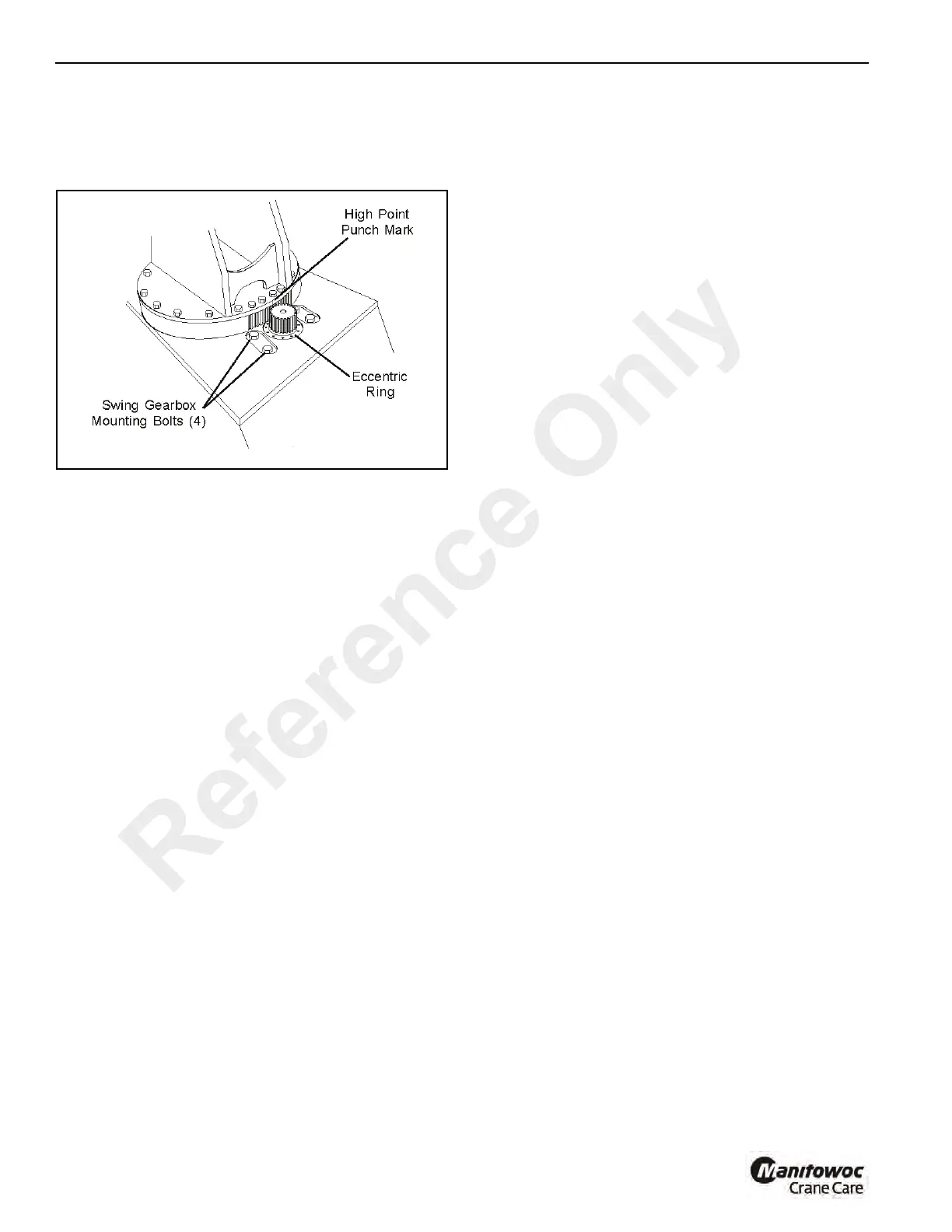

2. With a spanner wrench, turn the eccentric ring to move the pinion until it contacts the swing gear tooth (zero backlash).

3. Tighten the four bolts to appropriate torque.

4. Install the swing pinion cover.

Swing Gearbox Repair (Tulsa Gearbox)

Removal

1. Use a hoist and blocks to hold the boom in position and prevent the mast from rotating

2. Remove the swing motor from the gearbox.

NOTE: Do not rotate the mast after the hydraulic motor has been removed from the gearbox. Internal bearings will become

dislodged. Make note of the position of the swing motor for installation.

3. Provide support for the gearbox and remove the four bolts which fasten the gearbox to the frame. Remove the gear box

and eccentric ring from beneath the machine.

Disassembly

1. Clean the outside of the gearbox before disassembly.

2. Loosen bolts (23, Figure 11-127) from cover 22). Remove the cover from the gear housing 25.

3. 3.Clean as much grease out of the housing as possible. Properly dispose of the grease.

NOTE: Tie the shim sets together to inhibit any shim from being lost.

4. Remove shims 19 through 21 from the gear case. Be careful not to damage or lose any of the shims.

5. Remove o-ring 18 and cover 22.

6. Remove socket head capscrews 13. Remove end motor cap 12.

7. If shims 9 though 11 are located between cover 12 and housing 25 remove the shims. Be sure not damage of lose any of

the shims.

8. Remove and discard o-ring 7 and seal 8.

9. Remove capscrews 28 and remove end cap 27.

10. If shims 9 through 11 are located between cover 27 and housing 25 remove the shims.Be sure not damage of lose any of

the shims.

11. Remove and discard o-ring 7 from end cap 27.

12. Using a suitable puller, remove bearing cup 5 from end cap 27. Remove and discard seal 8.

Reference Only

Loading...

Loading...