Grove Published 1-20-2017, Control# 483-02 11-23

CD5515-2/YB5515-2 SERVICE MANUAL STRUCTURALS

Planetary Set

NOTE: See Figure 11-16 for item number identification.

1. Remove the spiral retaining rings from the planet pins.

2. Remove the pins from the carrier by carefully tapping

them out.

3. Remove the planet gears, thrust washers and bearings

from the carriers.

4. Inspect the pins, bearings, and gear bores for evidence

of wear and replace if necessary.

5. On output planet sets, note that two bearings with a

spacer between them are used.

6. Before reassembly, be sure to insert the round plates

into the carriers.

7. To re-assemble, be careful to line up the planet pins with

the thrust washers and bearings and then press the

knurled part of the pin into the carrier.

Motor

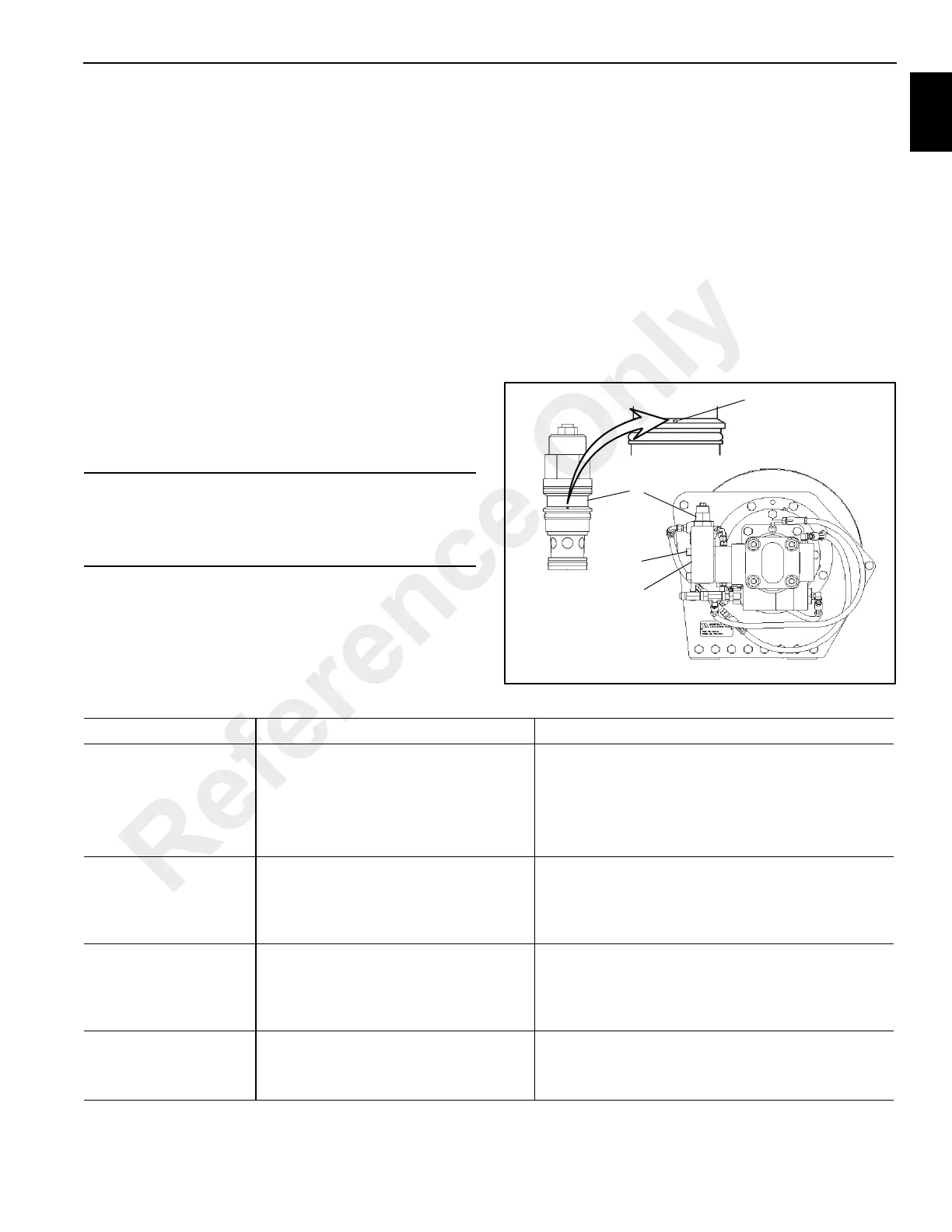

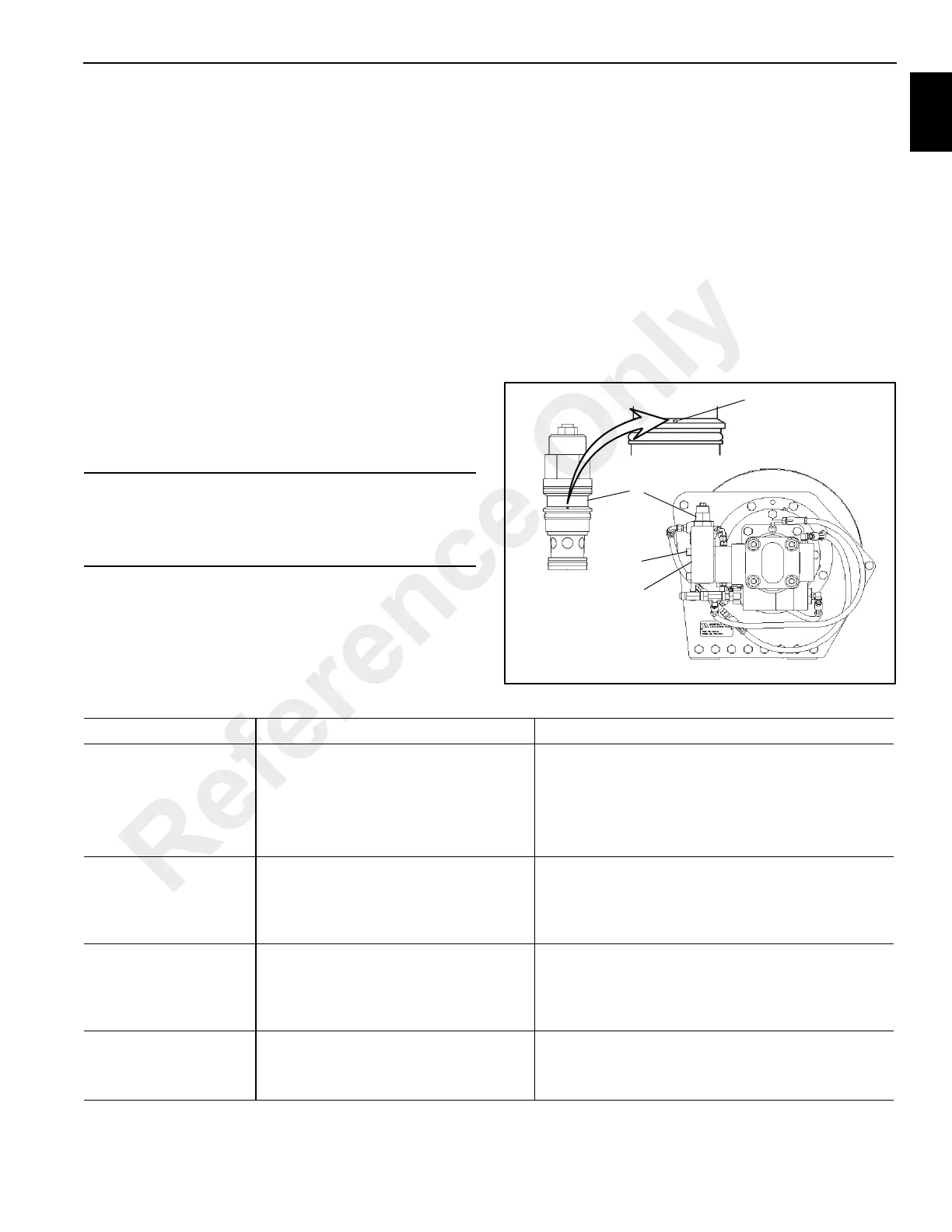

1. Remove the hose and the counterbalance block (42)

from the motor assembly.

2. To remove the counterbalance block (42), loosen and

remove the 4 capscrews (55).

3. Remove the counterbalance valve (58) from the

counterbalance block and inspect the small metering

hole located on the side of the cartridge valve to make

sure it is not obstructed (Figure 11-17). Also inspect the

O-rings to insure that they are not cut or flattened.

4. Motors and cartridge valves are not serviceable in the

field. Return them to an authorized distributor for

service.

CAUTION

Possible Equipment Damage!

If the pins are not lined up properly, the thrust washers

can be shattered during the pressing operation.

FIGURE 11-17

2

3

1

Metering Hole

7148

7147

TROUBLESHOOTING

Problem Cause Solution

Hoist does not hold

load

Excessive back pressure in the system.

Check the system for restrictions and reduce the

back pressure.

Brake discs are worn out. Replace brake discs.

Hoist clutch is slipping.

Inspect the clutch and driver for wear and replace

worn parts.

The hoist does not

raise the load it should.

Relief valve setting may be too low to

allow proper lifting.

Increase relief valve pressure setting.

Load being lifted may be more than the

hoist's rating.

Reduce the load or re-rig to increase mechanical

advantage.

The hoist does not

lower the load.

The brake valve was connected

improperly after being disconnected.

Check plumbing and connect lines properly.

The cartridge in the brake valve may

have a plugged metering hole.

Remove the cartridge and clean it if necessary.

Oil leaks from the vent

on the motor side of the

hoist.

The motor shaft seal may have failed.

Replace this seal and reduce back pressure if high

pressure caused the shaft seal to fail.

Brake piston seals may have failed. Service the brake section and replace worn parts.

Reference Only

Loading...

Loading...