GROVE Published 1-20-2017, Control# 483-02 8-19

CD5515-2/YB5515-2 SERVICE MANUAL AXLES/DRIVE SHAFTS/WHEELS AND TIRES

REAR AXLES REPAIR

Removal

1. Loosen the wheel lug nuts and raise and support the

crane on axle stands or blocks positioned under the

chassis frame. Remove the wheels.

2. Disconnect the drive shaft from the axle by removing

four bolts and lockwashers.

3. Disconnect and plug the hydraulic hoses to the steering

cylinder.

4. Disconnect, cap and plug the brake hoses from the axle.

5. Support the axle on a trolley jack.

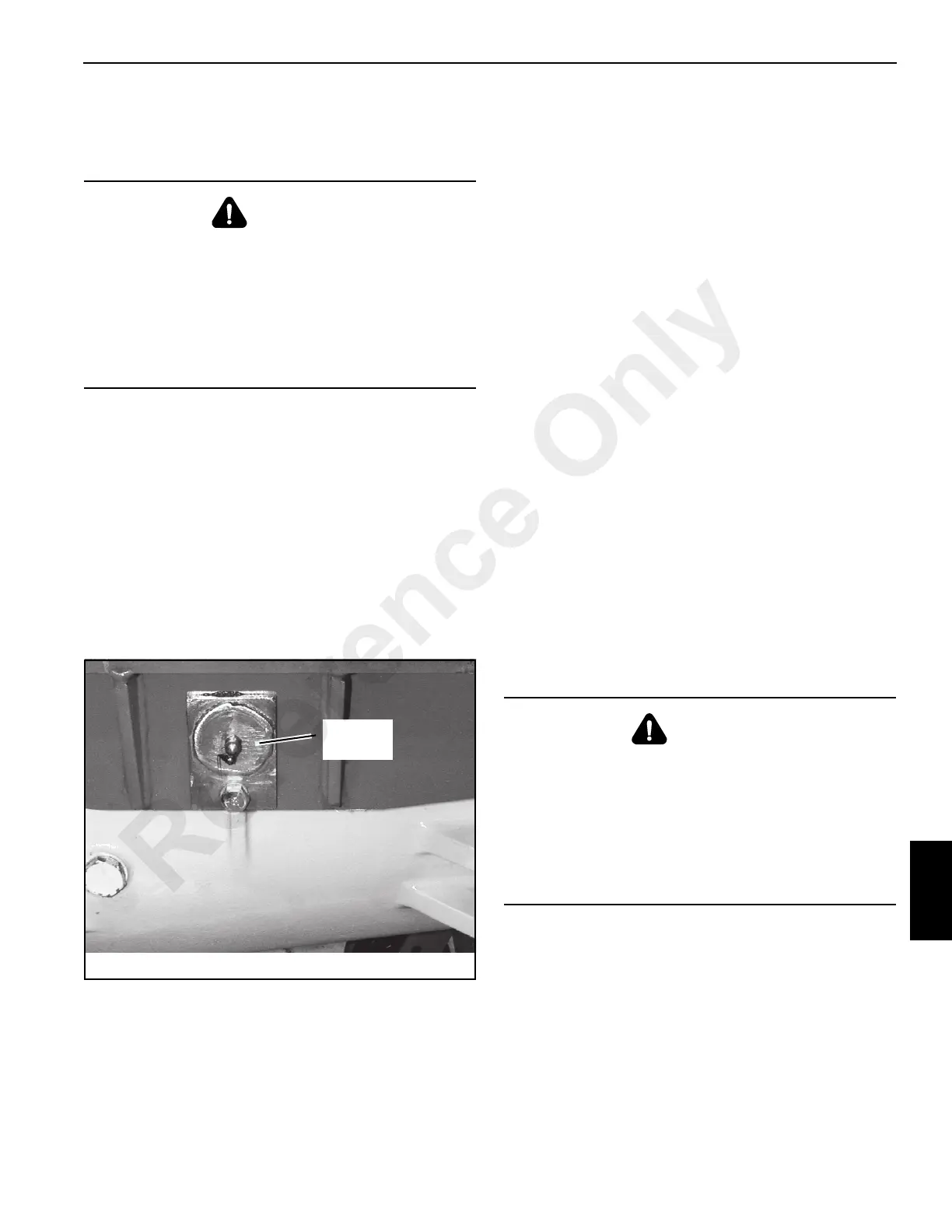

6. Remove the bolt and lockwasher Figure 8-43 securing

the axle pivot pin. Remove the axle pivot pin.

7. Lower the axle clear of the mounting bracket and

remove it from the crane.

Installation

1. Place the axle on a trolley jack and position it under the

crane frame.

2. Raise axle and position it in the mounting frame.

3. Install the axle pivot pin.

4. Coat the threads of the pin retaining bolt with Loctite®

243 and then secure the axle pivot pin with the bolt and

lockwasher.

5. Grease the axle pivot pin through two grease fittings.

6. Connect the brake lines and the steering lines to the

axle.

7. Bleed the air from the brake system. See Section 9.

8. Bleed the air from the steering circuit. See Section 10.

Service Tools

To completely disassemble and assemble the rear axle,

special tools are required. Unless you have the tools

illustrated Figure 8-3, DO NOT service the axle.

Replacing the Pinion Oil Seal

The procedure for replacing the pinion or seal on the rear

drive axle is the same as the front drive axle. Refer to

page 8-6 for replacement procedures.

Axle Hub Repair

Disassembly Figure 8-45

1. Disconnect the track rod and steering cylinders.

NOTE: If the track rod is removed completely, identify R.H.

and L.H. ends to ensure correct assembly.

2. Drain all oil from the hub.

3. Remove screws 33 Figure 8-45.

4. Pry off planet gear carrier 27 at the pry points. Remove

and discard O-ring 32.

WARNING

A raised and badly supported crane can fall on you

causing severe injury or death. Position the crane on a

firm, level surface before raising one end. Ensure that the

other end is securely chocked. Do not rely solely on the

crane hydraulics or outriggers to support the crane when

working under it.

Disconnect the battery cables while you are under the

crane, to prevent the engine from being started.

FIGURE 8-43

p0082

Axle

Pivot Pin

WARNING

A raised and badly supported crane can fall on you

causing severe injury or death. Position the crane on a

firm, level surface before raising one end. Ensure that the

other end is securely chocked. Do not rely solely on the

crane hydraulics or outriggers to support the crane when

working under it.

Disconnect the battery cables while you are under the

crane, to prevent the engine from being started.

Reference Only

Loading...

Loading...