14

Pellerin Milnor Corporation

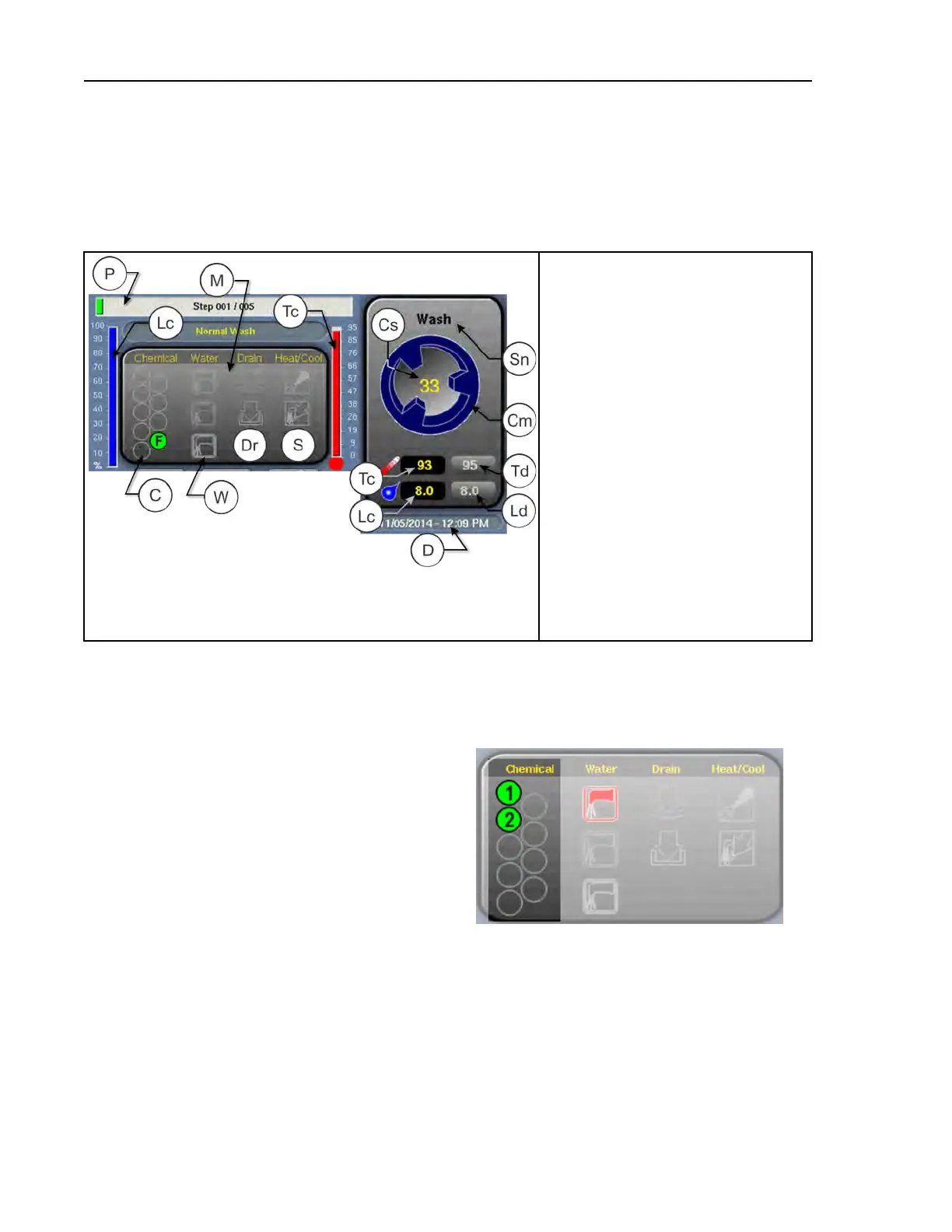

3.7.1.2 The Machine Status Area (B)

BNCLJO07.C05 0000187329 A.10 C.5 F.2 9/11/20 10:31 AM Released

This area displays the current and desired water level and temperature for the step in progress, the

current cylinder motion, and the current state of each valve.

Figure 10. The Machine Status Area

Legend

C...Chemical signals and chemical

flush valve. Numbers 1–8 indicate

a chemical is being injected. F indi-

cates a chemical flush is occurring.

Cm..Cylinder motion

Cs..Cylinder speed, in rotations per mi-

nute. Displays “RS” during Rin-

Save

®

extract deceleration.

D...Date and time

Dr..Drain indicators

Lc..Current level (percentage)

Ld..Desired level

M...Current machine status area

P...Formula progress bar

S...Steam and cooldown indicators

Sn..Step name

Tc..Current temperature

Td..Desired temperature

W...Water valve indicators

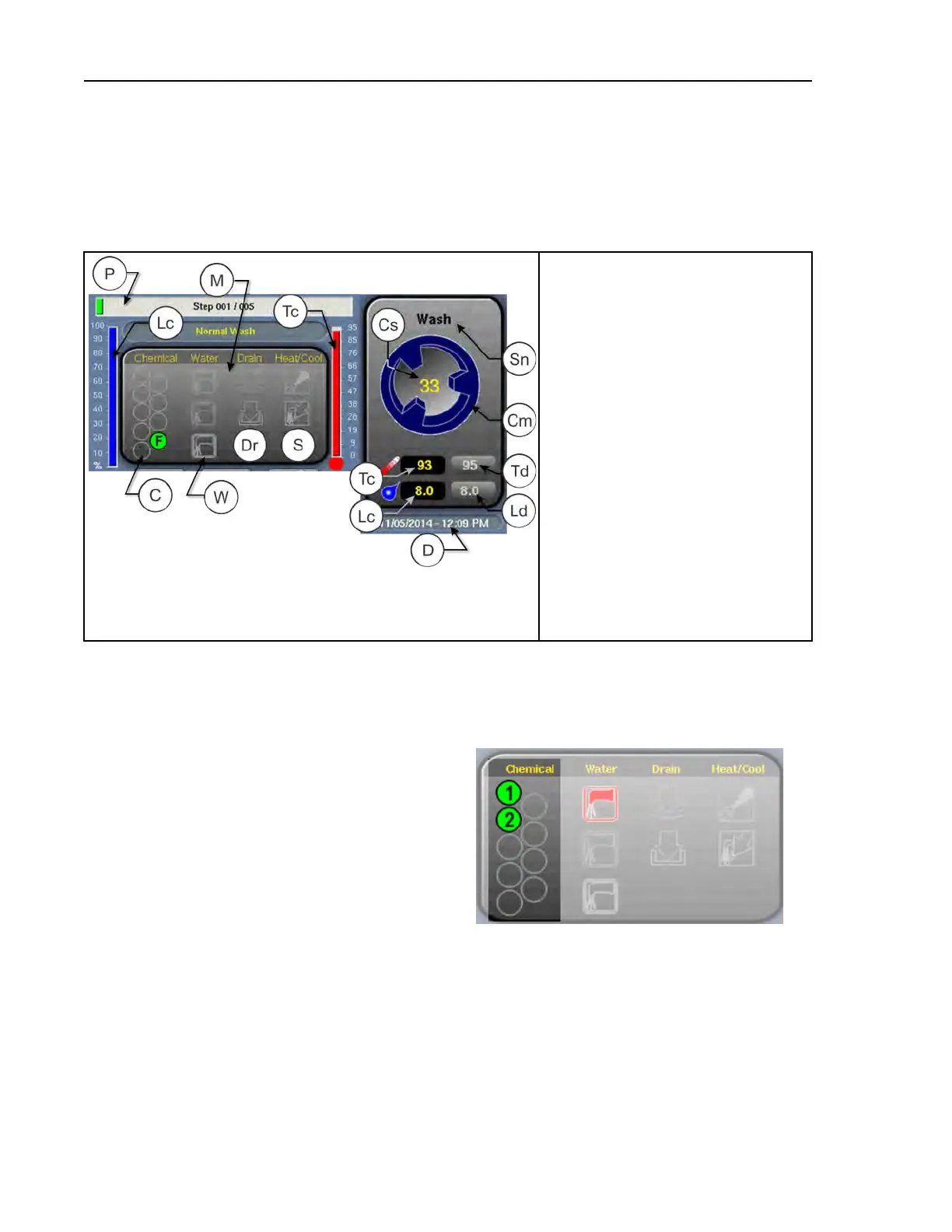

3.7.1.2.1 How to Monitor Automatic Liquid-Chemical Injections

BNCLJO11.C04 0000214843 A.10 C.5 C.2 9/11/20 10:33 AM Released

Figure 11. Chemicals from Valves 1 and 2

Injecting

If your machine controls a pumped chemical sys-

tem, the controller automatically injects chemi-

cals from the pump system while the formula

runs.

You can monitor automatic liquid-chemical in-

jections in the Machine Status area. As the con-

troller injects a chemical into the machine, the

chemical’s valve number illuminates, as shown

in Figure 11 , until the programmed injection

time expires.

3.7.1.3 Manual Control and Diagnostics Area (C)

BNCLJO11.C03 0000213316 A.10 C.5 C.3 9/11/20 10:35 AM Released

Use these buttons as explained in the following figure.

Normal Operation

17

Loading...

Loading...