15. USING A LINEAR SERVO MOTOR

15 - 21

(3) Program operation

Positioning operation can be performed in two or more operation patterns combined, without using a

controller. Use this operation with the forced stop reset. This operation may be used independently of

whether servo-on, servo-off, or whether a controller is connected or not.

Exercise control on the program operation screen of MR Configurator2. For full information, refer to the

MR Configurator2 Installation Guide.

Operation Screen control

Start Click the "Operation start" button.

Pause Click the "Pause" button.

Stop Click the "Stop" button.

Forced stop Click the "Forced Stop" button.

15.3.5 Function

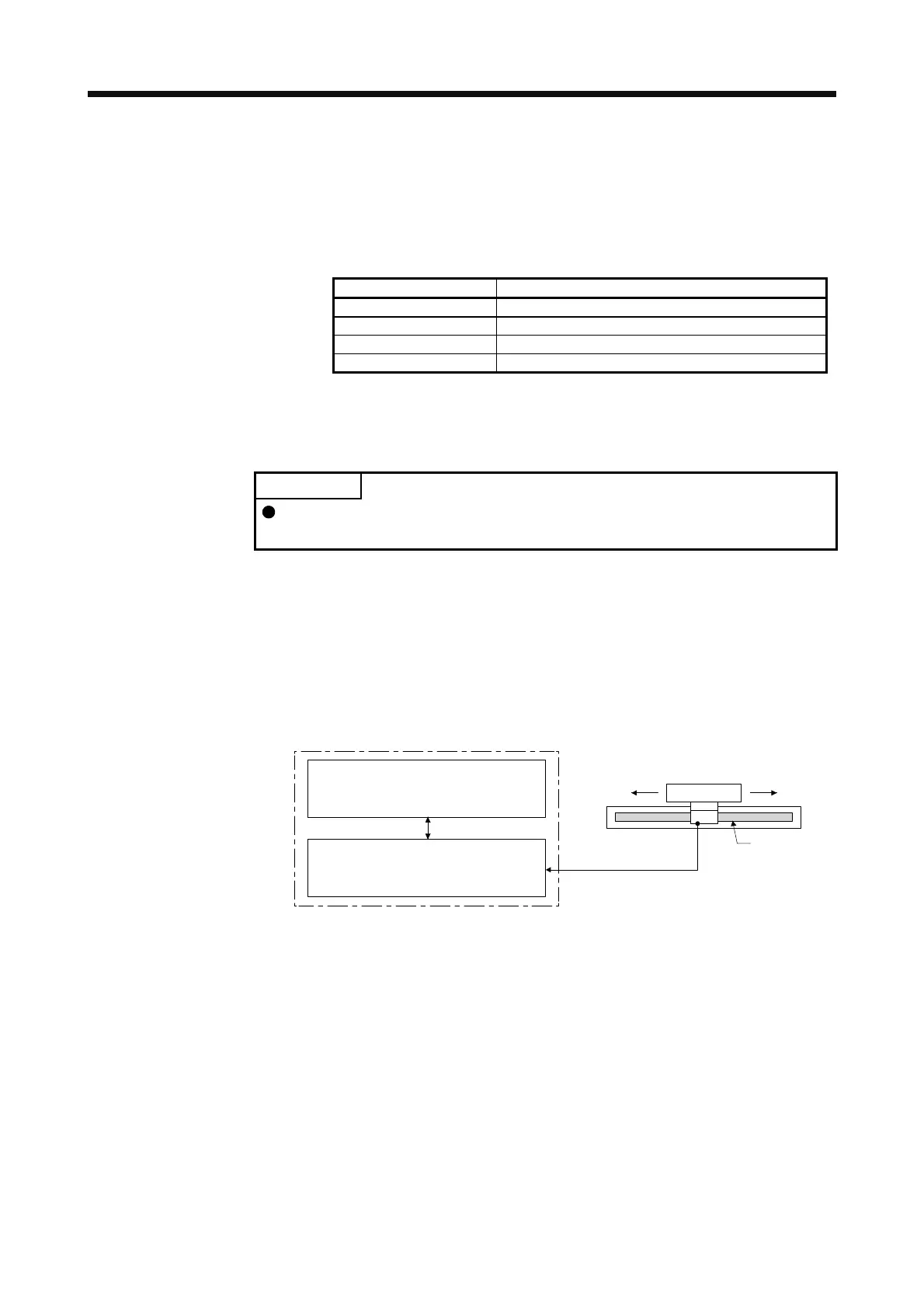

(1) Linear servo control error detection function

POINT

For the linear servo control error detection function, the position and speed

deviation error detections are enabled by default. ([Pr. PL04]: _ _ _ 3)

If the linear servo control gets unstable for some reasons, the linear servo motor may not operate

properly. To detect this state and to stop operation, the linear servo control error detection function is

used as a protective function.

The linear servo control error detection function has three different detection methods: the position

deviation, speed deviation, and thrust deviation. An error is detected when each method is enabled with

[Pr. PL04 Linear servo motor/DD motor function selection 2]. The detection level can be changed with

[Pr. PL05], [Pr. PL06], and [Pr. PL07].

Servo amplifier internal value

1) Model feedback position [mm]

3) Model feedback speed [mm/s]

5) Command thrust [%]

Linear encoder

2) Feedback position [mm]

4) Feedback speed [mm/s]

6) Feedback thrust [%]

Servo amplifie

Linear servo motor

Linear encoder

Figure 15.1 Outline of linear servo control error detection function

Loading...

Loading...