1 - 3 1 - 3

MELSEC-Q

1 GENERAL DESCRIPTION

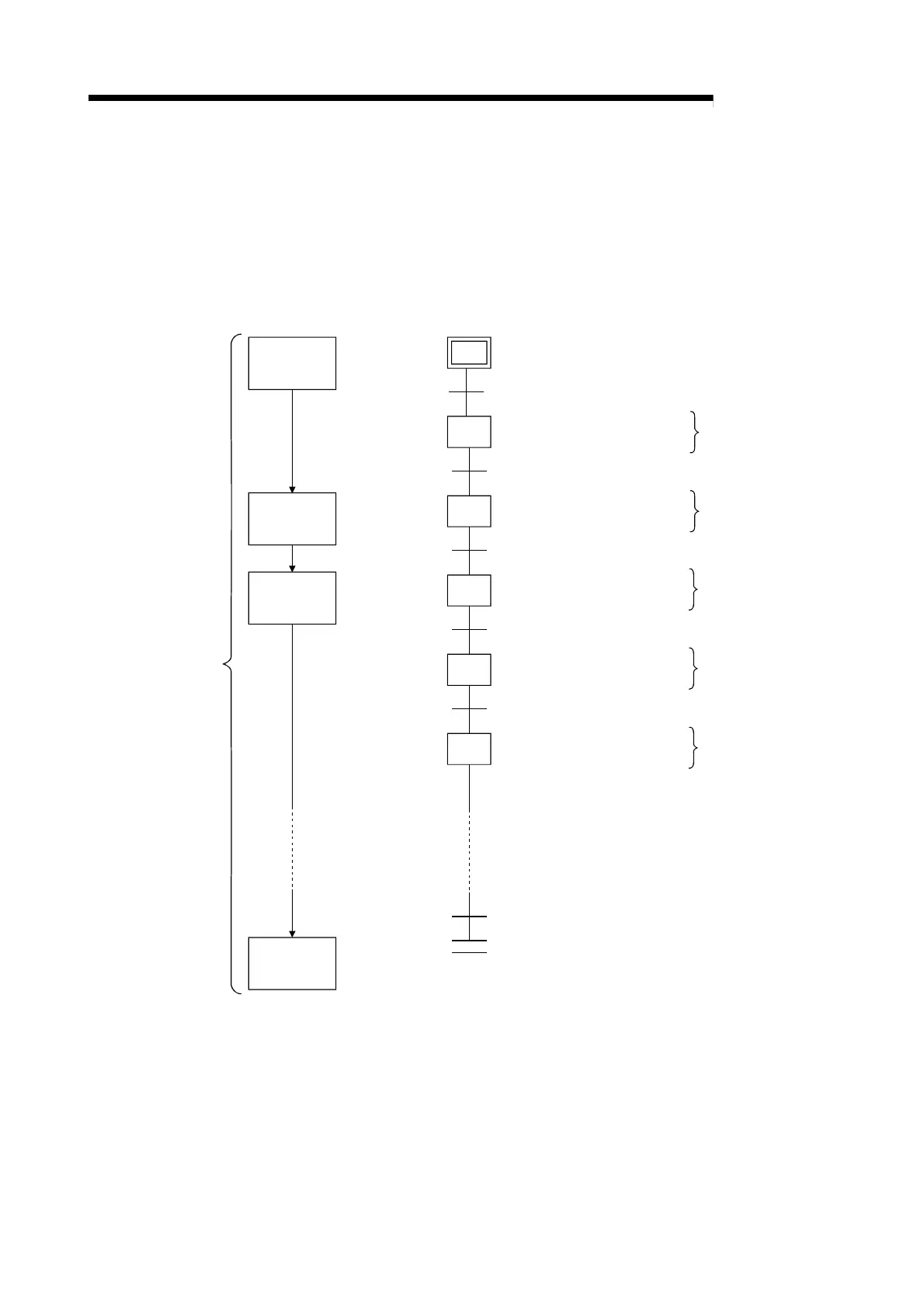

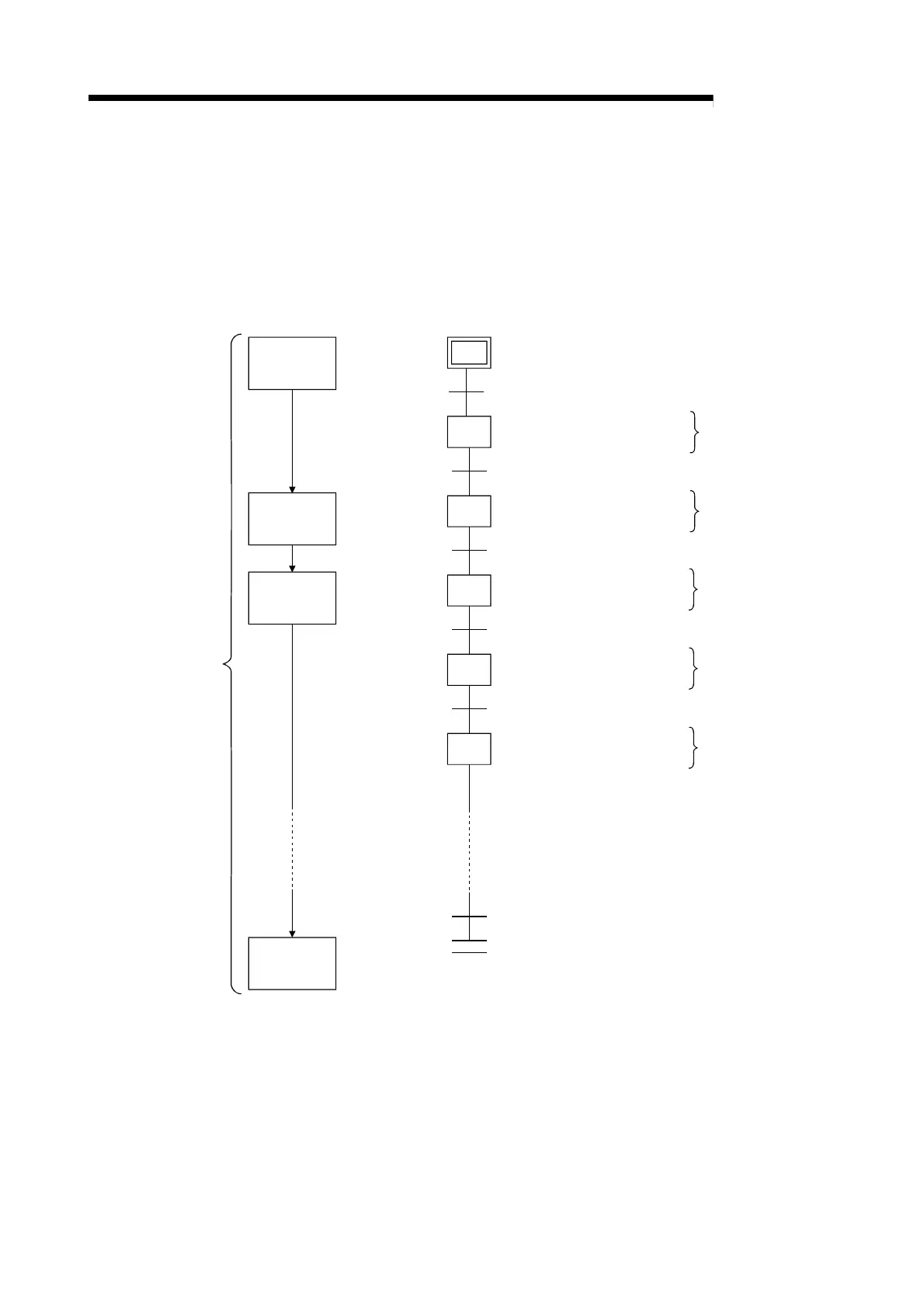

1.1 SFC Program

The SFC program consists of steps that represent units of operations in a series of machine

operations.

In each step, the actual detailed control is programmed by using a ladder circuit.

Grouping steps into one block in process units allows to create an SFC program that is capable of

tracking all the processes as well as structuring the operation flow in each process.

Workpiece

detection

Workpiece

loading

Drilling

operation

Machining

completed

Whole process

Workpiece unloaded confirmation

aX0 & aX1

oY20

aX2

oY21

aX3

oY22 ,PLS M0

pM0

rY23, oT0 K20

aX7

sY23

aX4

END step

Initial step

Transition

condition 0

step 1

Transition

condition 1

step 2

Transition

condition 2

step 3

Transition

condition 3

step 4

step 5

Transition

condition n

START switch, Workpiece detection

Conveyor START

Clamp confirmation

Pallet clamp

Drill rotation

Drill DOWN

Drill Down stop

Pallet detection

Drill DOWN endpoint

1 operation unit

1 operation unit

1 operation unit

1 operation unit

1 operation unit

[Process flow chart] [SFC diagram]

[Operation output/transition condition]

Transition

condition 4

The SFC program performs a sequence of operations, beginning from the “initial” step,

proceeding to each subsequent step as the transition conditions are satisfied, and ending at the

“END” step.

(1) When the SFC program is started, the “initial” step is executed first.

(2) Execution of the initial step continues until transition condition 0 is satisfied. When this

transition condition is satisfied, execution of the initial step is stopped, and processing

proceeds to the step which follows the initial step.

Processing of the SFC program continues from step to step in this manner until the END step has

been executed.

Loading...

Loading...