6-3

Chapter 6 COOLANT

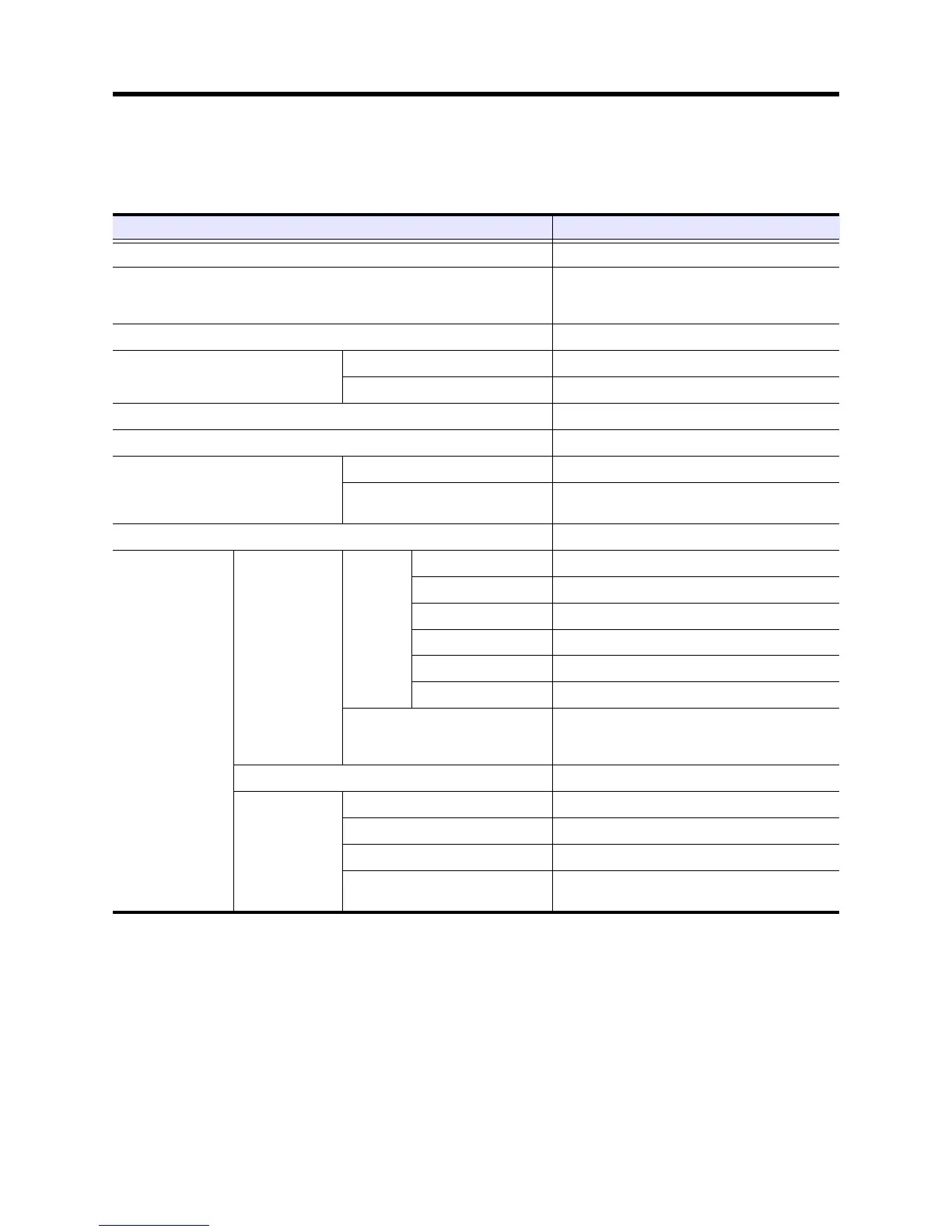

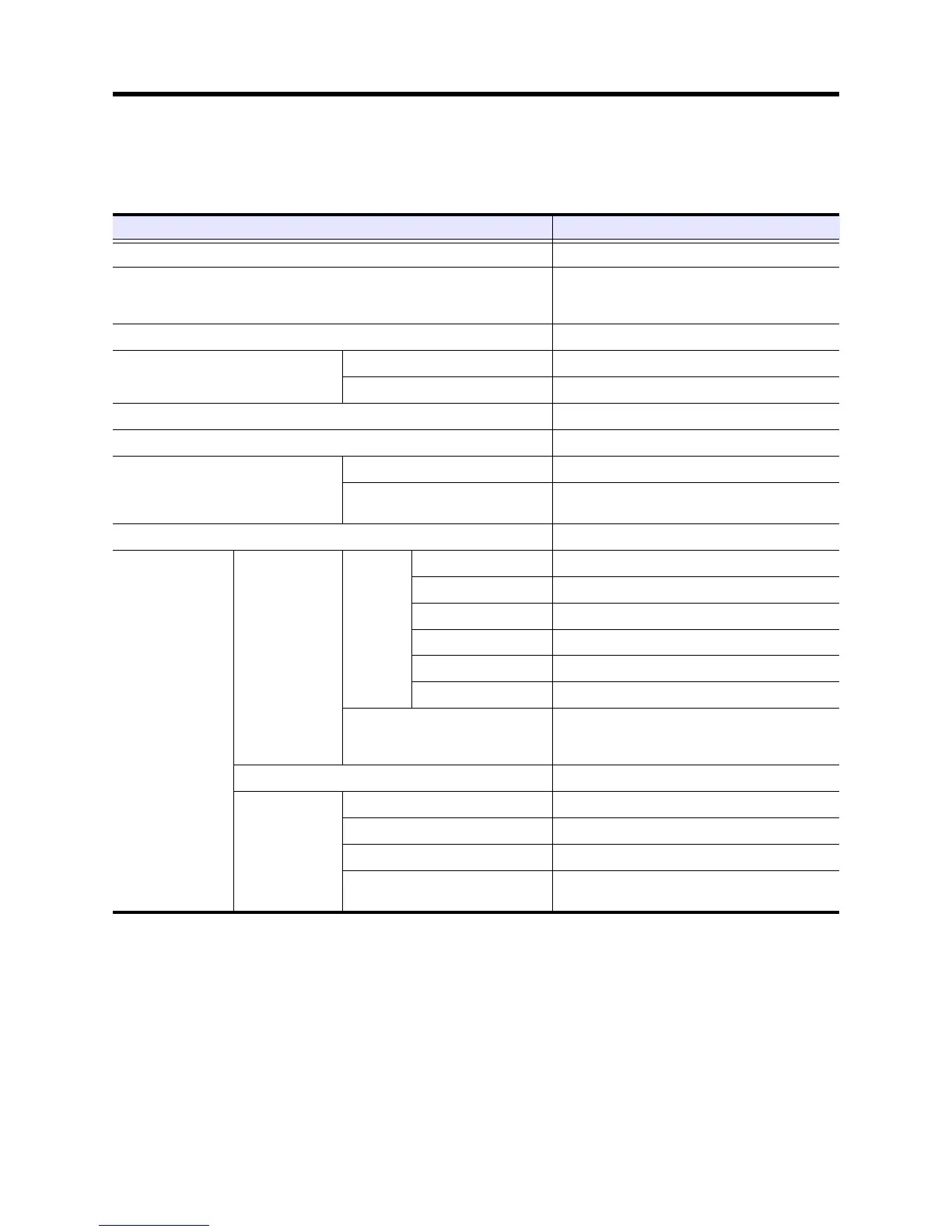

LLC Quality Requirements

LLC shall be tested according to JIS K2234, Section 7 "Test method", and satisfy the requirements. General mat-

ters and specimen sampling method shall comply with JIS K2234.

Table 6-2 LLC Quality Requirements

Property Standard

Appearance No precipitation

Density

Minimum 1.112 g/cm

3

[69.4199 lb/ft

3

] (20/20 °C) [68/68 °F]

(Stock solution)

Water content Maximum 5.0 weight % (Stock solution)

Frozen temperature

30 vol % Maximum -14.5°C [5.9°F]

50 vol % Maximum -34.0°C [-29.2°F]

Boiling temperature 155°C [311°F] or higher (Stock solution)

pH 7.0 to 11.0 (30 vol %)

Bubbling character

(ASTM D3306-01)

30 vol % 4.0 ml or less

33

1/3 vol %

150 ml [0.032 gal] or less, disappearance of

bubble within 5 seconds.

Hard water adaptability 1.0 or less (50 vol %)

Metallic causticity

(88 ± 2°C

[190 ± 3.60°F],

336 ± 2 Hr,

30 vol % (E.G),

50 vol % (P.G)

Metal speci-

men

Mass

change

Aluminum ±0.30 mg/cm

2

Cast iron ±0.15 mg/cm

2

Steel ±0.15 mg/cm

2

Brass ±0.15 mg/cm

2

Solder ±0.30 mg/cm

2

Copper ±0.15 mg/cm

2

Appearance of the specimen

after testing

No visible signs of corrosion on the surface

excluding the area contacted to the spacer.

However, discoloration is acceptable.

Bubbling during the test No bubbles overflowing

Properties of

liquid after

testing

pH 6.5 to 11.0

pH change ±1.0

Precipitation 0.5 vol % or less

Appearance of liquid

No remarkable discoloration, separation

and gel generation.

Loading...

Loading...