8-21

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES

Inlet and Exhaust Systems

Turbocharger - Inspect

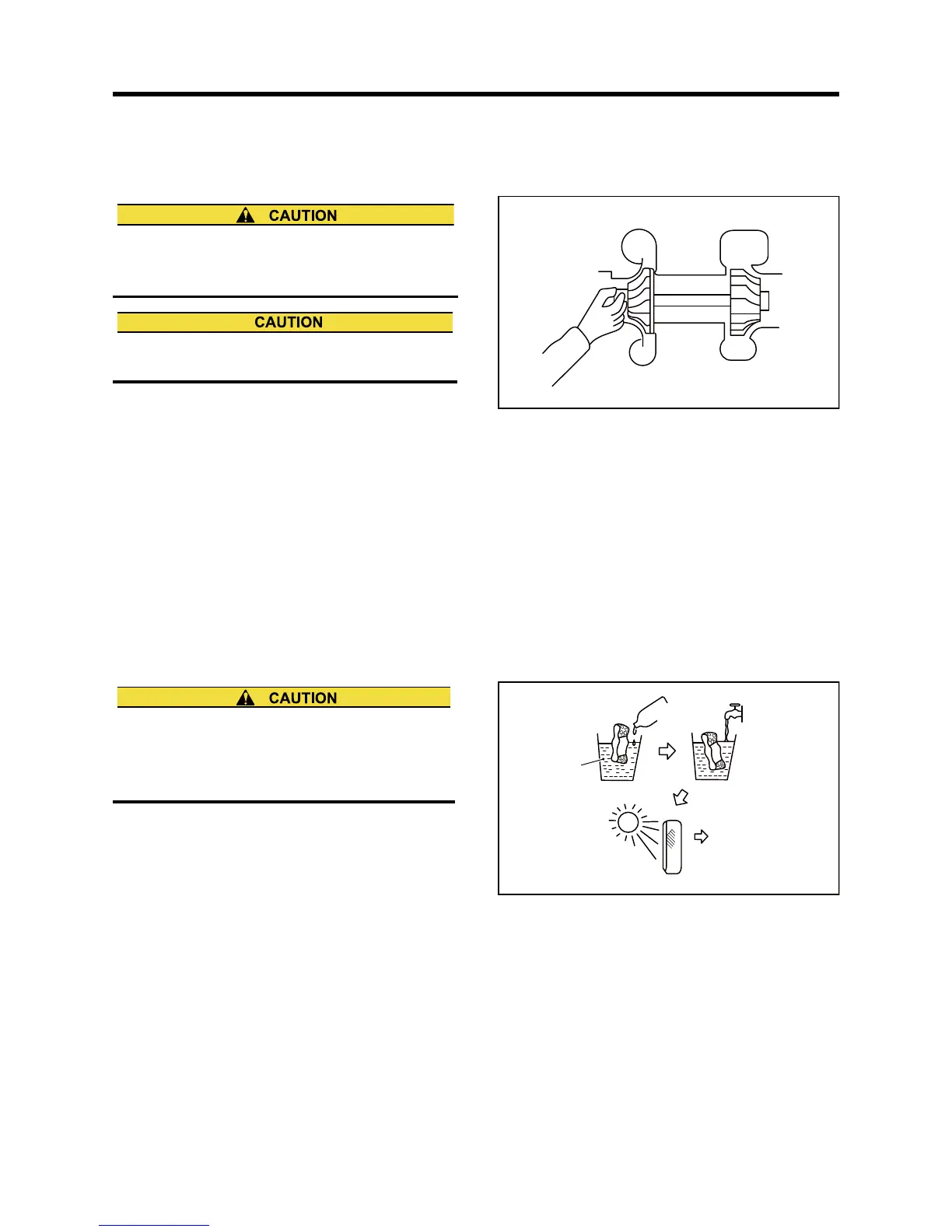

Disconnect the pipe on the inlet side. Hold the com-

pressor wheel nut by hand and move in the axis direc-

tion and from right to left and up and down to check

looseness. Turn the wheel to check if it rotates

smoothly. Replace if there is looseness or the wheel

does not rotate smoothly.

Note: When the inspection requires the removal of tur-

bocharger, contact your local dealer.

Also check the compressor wheel fins for discol-

oration and breaks, and check for rubbing be-

tween compressor wheel and housing.

Fig. 8-27 Turbocharger - Inspect

Pre-cleaner - Clean, Inspect and Replace

The pre-cleaner, which is attached to the silencer of

the turbocharger, prevents foreign materials from

entering the engine and keeps the engine clean for

optimum performance. Always keep it clean as

instructed below.

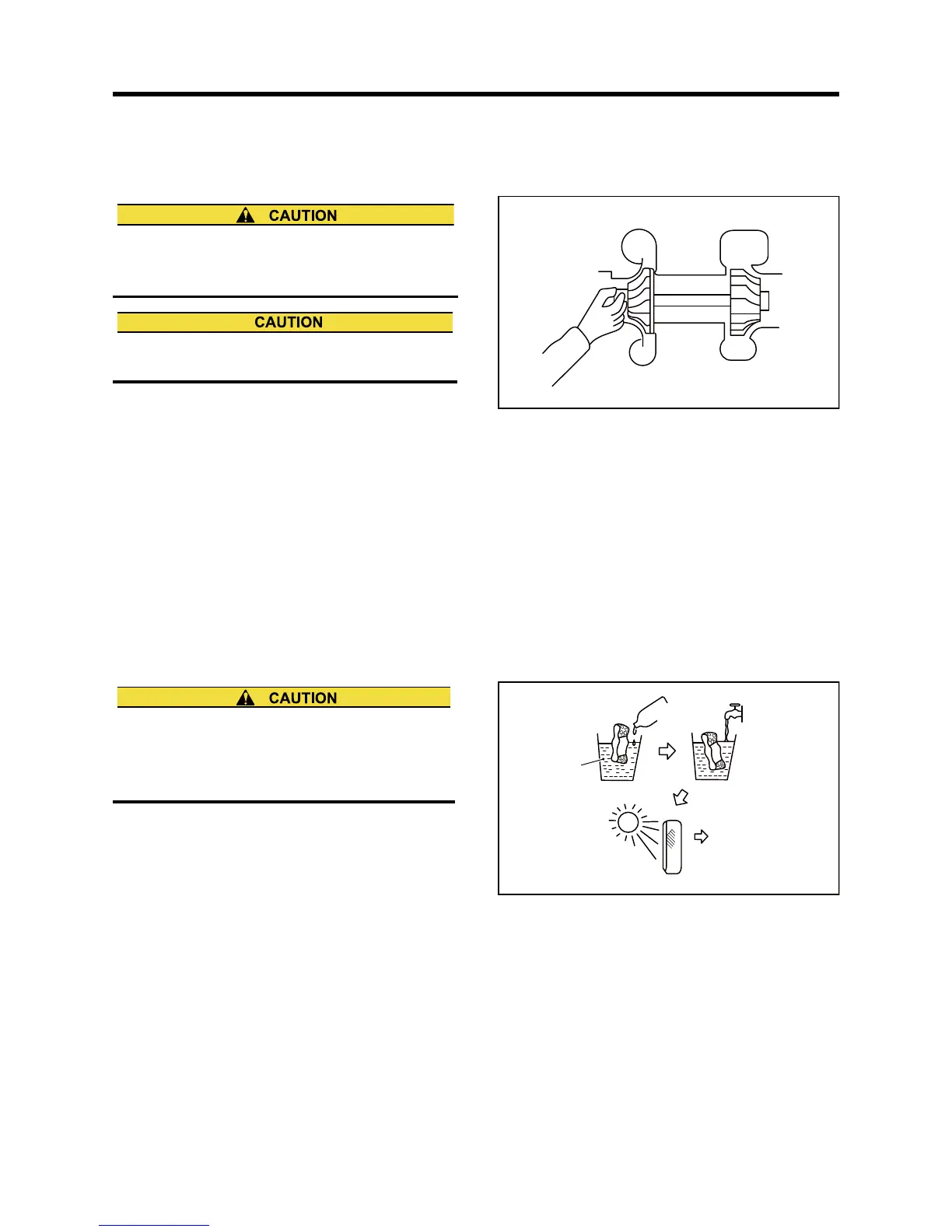

1. Remove the pre-cleaner from the silencer, and

hand-wash the pre-cleaner with a mild detergent.

2. Rinse the pre-cleaner with fresh water.

3. After drying thoroughly, inspect the pre-cleaner for

damage such as breaks. If breaks or etc. are found,

replace the pre-cleaner with a new one.

4. After cleaning, inspection or replacement, install

the pre-cleaner to the silencer.

Fig. 8-28 Pre-cleaner - Clean

Inspect the turbocharger when the engine is cold.

Also, make sure that the compressor wheel is not

rotating.

The turbocharger inspection should be also con-

ducted if the color of the exhaust gas is abnormal.

Never remove pre-cleaners during engine operation

for cleaning or overhauling. If dust and dirt enter the

engine, it will cause rapid wear of parts, shortening

the service life of the engine.

Water

(Wash)

(Dry)

Install

(Rinse)

Mild

detergent

Loading...

Loading...