Operating manual X9 Series metering pumps

File: UT-4336 – Rev.0 Copyright © - OBL Metering pumps - All rights reserved Page 19

GB

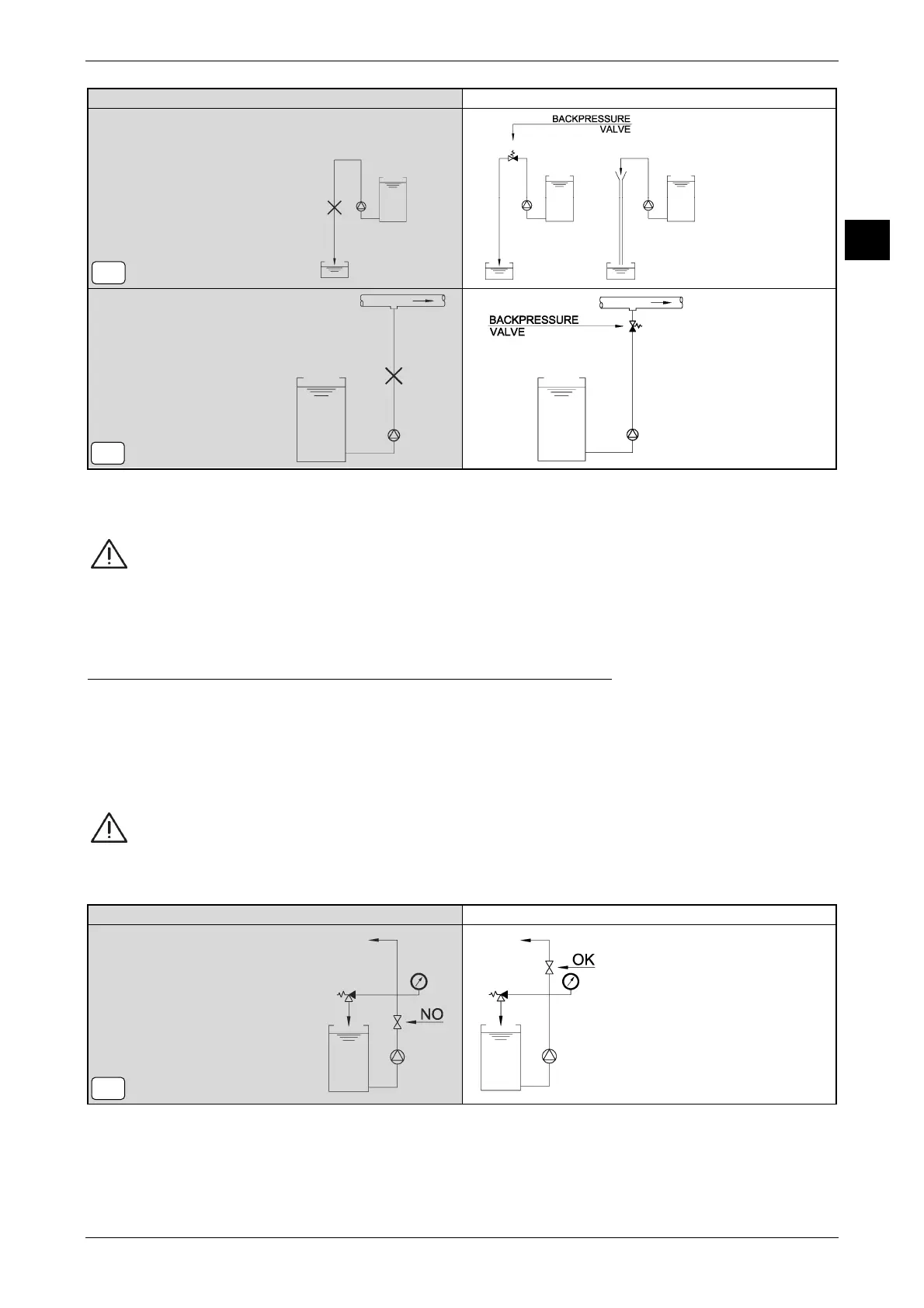

Figure 8 INCORRECT INSTALLATION CORRECT INSTALLATION

6.3.1

External safety valve

As a general rule, it is always suggested to install an external safety valve on the discharge pipeline, near the pump and before any

accessories. This allows to increase the "intrinsic" safety level of the plant.

The EXTERNAL safety valve on the discharge pipeline is essential when plant pressure can rise quickly,

unexpectedly and uncontrollably, regardless of pump operation.

The external safety valve must be installed immediately after pump discharge connection and, in any case, before the ON-OFF valve

(see figure 9). The discharge of safety valve must be visible, inspectable and directed back to the suction tank or into a drainage.

Avoid to connect the discharge to the pump suction pipeline (recirculation), especially on small flow rate pumps.

Consider the use of an external safety also when dosing in a "free discharge / open flow" plant.

Doing so prevents accident caused by the following risks:

- freezing or solidification of fluid in the pipeline

- obstruction or accidentally squashing of the discharge pipeline (flexible pipes)

- variation of fluid viscosity in relation to the temperature

- when dosing the fluid through the injection nozzles

- other unforeseen risks that may cause quick, uncontrolled rise in pressure

ATTENTION: X9 pumps are protected by an internal safety valve. To protect the plant we recommend installing

an external safety valve on the discharge pipeline.

The external safety valve pressure opening (calibration) must be lower than the internal of the pump (see nameplate).

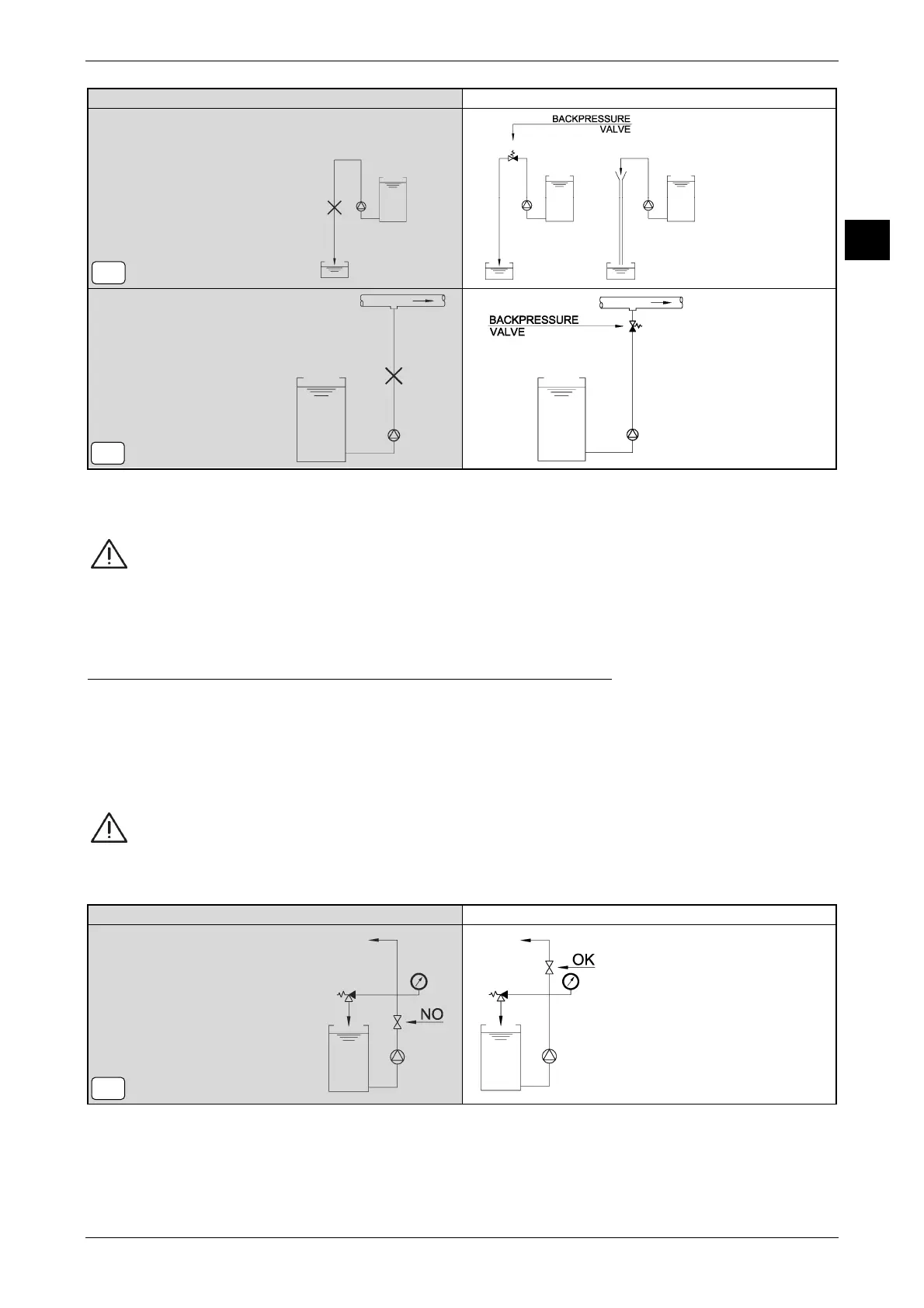

Figure 9 INCORRECT INSTALLATION CORRECT INSTALLATION

Siphon effect and uncontrollable

flow rate

8-A

The flow in the discharge

pipe

line uncontrollably draws the

fluid present in the tank

8-B

Safety Valve must be installed BEFORE

(upstream) the ON-OFF valve

9-A

Loading...

Loading...