X9 Series metering pumps Operating manual

Page 28 Copyright © - OBL Metering pumps - All rights reserved File: UT-4336 – Rev.0

GB

In multiple pumps each pump body has its own lubrication, independent from the others. Operate individually

on each pump body to change all multiple pump lubricating oil.

FIRST lubricant oil change after 1.000 hours of operation. For standard pump version replace oil after every

15.000 operating hours and every 10.000 hours for ATEX pumps. In any case every 5 years.

NOTE: Chemically contaminated lubricants can cause wear, corrosion and leaking seals.

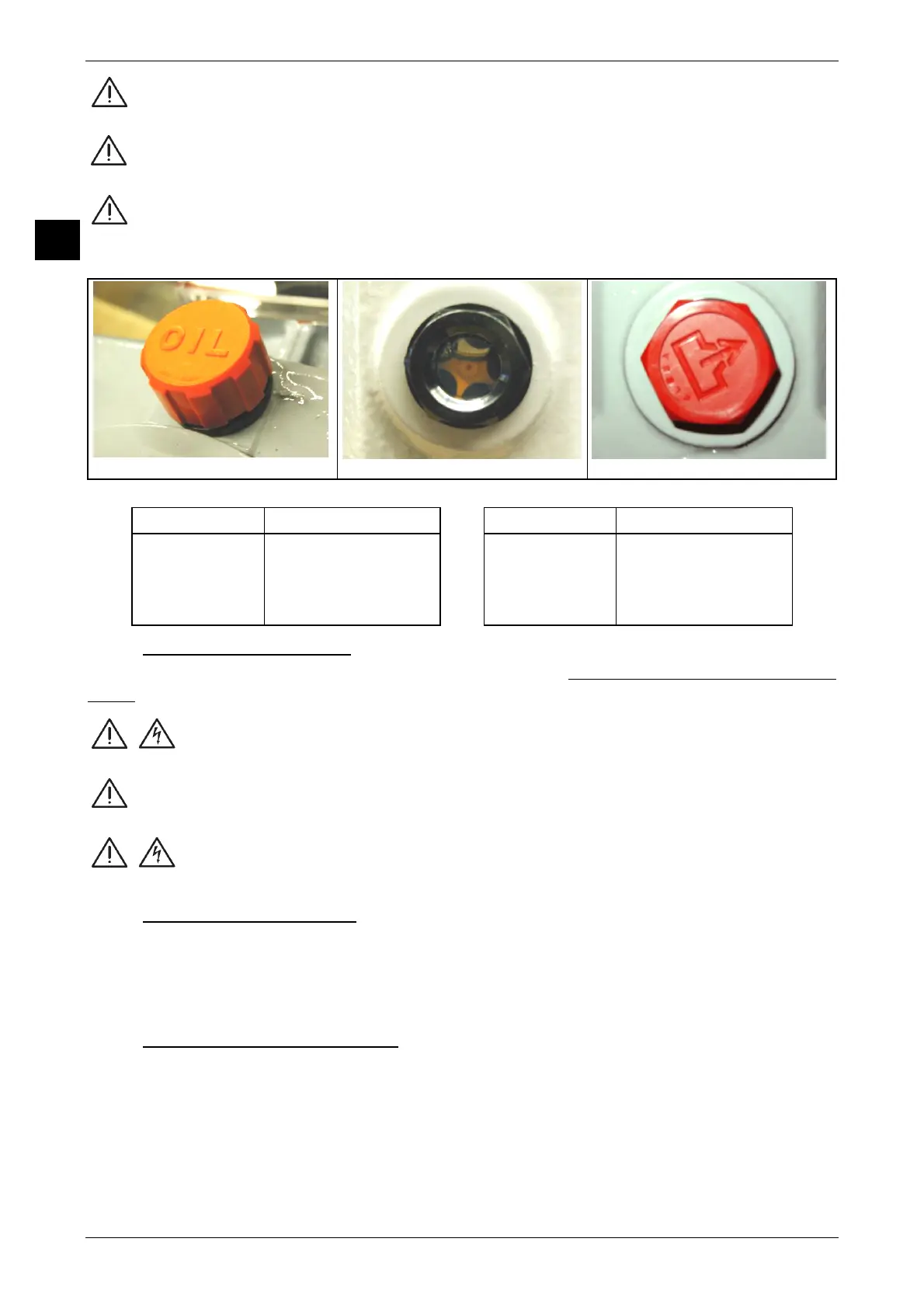

The oil filling plug (pos.119), the oil level plug (pos.120) and the oil drain plug (pos.121) are all placed on the reduction gear body.

The following images allow easy identification of the different plugs.

The oil filling plug (pos.119) The oil level plug (pos.120) The oil drain plug (pos.121)

Following table shown quantity and type of lubricant oils suggested:

OIL MAKE OIL TYPE/NAME PUMP TYPE QUANTITY (litres)

SHELL OMALA OIL 320 LY 0,85

ESSO SPARTAN EP 320 LYH 2,490

MOBIL MOBILGEAR 632 LK 3,25

IP MELLANA OIL 320 LN 4,75

AGIP BLASIA 320 LP 5,5

8. SPECIAL MAINTENANCE

The following guidelines cover the most common “special maintenance” operations that only an expert and trained technician can

perform. Avoid impromptu operations or attempts, contact OBL customer service for specific information.

These maintenance suggestions are not intended as "do-it-yourself" repairs. To perform such works,

specialised technical knowledge is required and operations are to be performed by qualified personnel.

ATTENTION: In the case of dosing anomalies, BEFORE start to dismantling the hydraulic system (pumphead),

verify the actual conditions of pumphead directional valves (see "Valve verify and/or replacement").

Appropriate individual safety devices must always be used to ensure and safeguard the personal safety

of personnel, who must also be properly trained and professionally qualified.

8.1 TECHNICAL DOCUMENTATION

For "special maintenance" not expected, contact OBL customer care (Tel. +39-02-26919.1, info@obl.it) to receive:

- detailed and focused informations

- specific instructions copy (if available)

- sectional drawing updated copy

8.2 HYDRAULIC SYSTEM MAINTENANCE

X9 pump hydraulic system is equipped with an air-bleed valve, a mechanically actuated oil replenishing valve and a safety valve.

The three valves ensure that the pump has:

- perfect hydraulic balance, allowing operation without any air bubbles (air-bleed);

- impossibility of oil overloading due to clogging or shut-off of the suction pipeline, preventing the danger of impact of the

diaphragm against the front wall of the pumphead (mechanical replenishing);

- displacement recirculation in the event of overpressure or shut-off of the discharge pipeline (safety).

Loading...

Loading...