Operating manual X9 Series metering pumps

File: UT-4336 – Rev.0 Copyright © - OBL Metering pumps - All rights reserved Page 25

GB

7.3.6

Verification of thermal protections

Make sure that motor thermal overload protection is not excluded and is correctly set. Proper selection

and setting of overload protection for ATEX pump motors is essential to ensure the temperature class and safety

against explosion dangers.

7.3.7

Painting check (if foreseen)

In a corrosive environment, and every time it is needed, it is necessary check periodically that painting does not show deterioration

signs which can jeopardize the equipment protection degree.

Repaint the pump every time it is needed in order to protect the external surface from corrosion.

7.3.8

Lubricant oil check

X9 pumps are always supplied with lubricant oil on the mechanism.

Check daily that oil level is at the halfway of the oil level indicator and that there are no leaks from dynamic seals or from plugs on the

mechanism. Verify there is no oil contamination which may compromise the correct lubrication. Replace if necessary (see “Lubricant oil

change”).

7.3.9

Hydraulic oil system check

All hydraulic diaphragm pumps are always supplied with the hydraulic circuit filled with oil and ready for operation.

Make sure the tank cover is mounted and is always tightly closed.

Check weekly that oil level is at the halfway of the oil level indicator located on the tank, making sure there is no sludge or

contamination. Replace if necessary (see "Hydraulic oil system change").

7.4 RECOMMENDED SPARE PARTS

The most common faults can be solved by having the recommended spare parts in stock, thus avoiding unpleasant wastes of time.

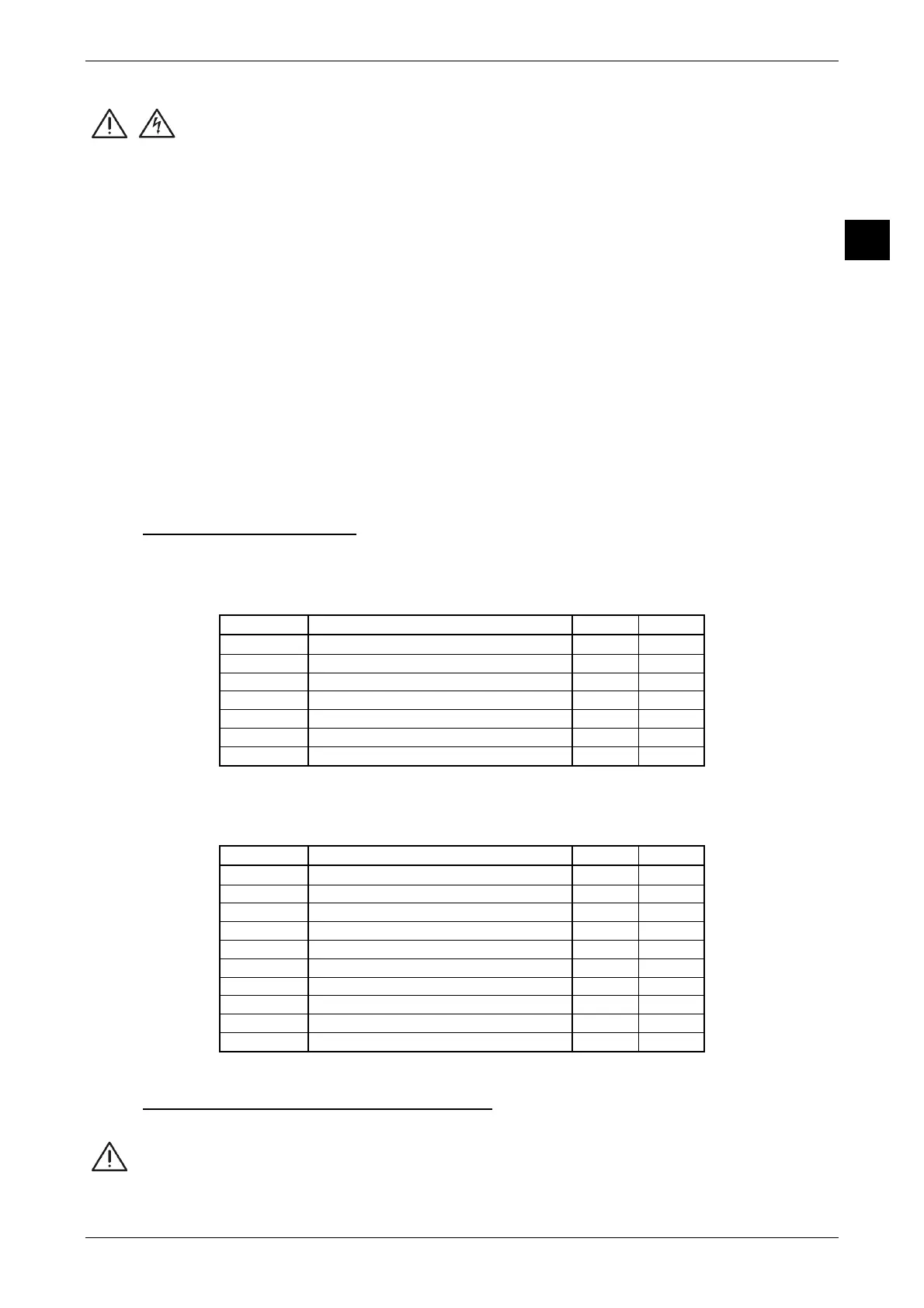

7.4.1

Pumps with PLASTIC material pumphead

This list is indicative; we suggest proceeding as detailed in "Instructions for requesting spare parts".

Position Component description SV * DV *

4 Plunger seal 2 2

5 Valve seat (Single Valve "SV") 2 2

6 Valve guide 2 4

8 Valve seat O-ring 2 4

9 Valve housing O-ring 2 2

15 Valve (sphere) 2 4

48 Diaphragm 1 1

NOTE * Suggested quantity: SV= Single Valve pumphead (standard OBL); DV= Double Valve pumphead

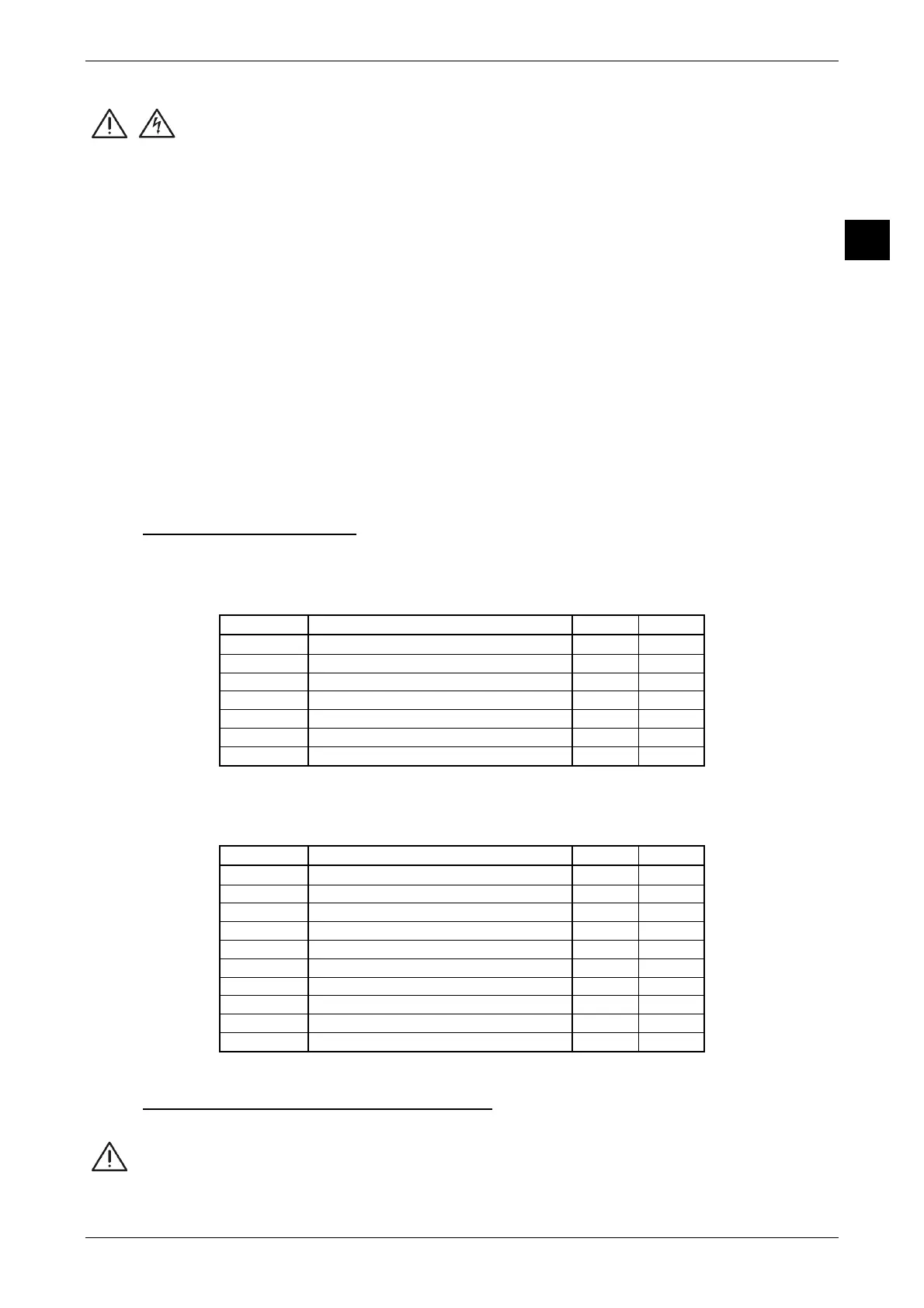

7.4.2

Pumps with METALLIC material pumphead

This list is indicative; we suggest proceeding as detailed in "Instructions for requesting spare parts".

Position Component description SV * DV *

4 Plunger seal 2 2

5 Valve seat (Single Valve "SV") 2 2

6 Valve guide 2 4

7 Valve seal 6 10

8 Valve seat O-ring 2 4

9 Valve housing O-ring 2 2

13 Valve seat (Double Valve "DV") 0 2

15 Valve (sphere) 2 4

48 Diaphragm 1 1

77 Valve guide O-ring 0 4

NOTE * Suggested quantity: SV= Single Valve pumphead (standard OBL); DV= Double Valve pumphead

7.5 DISMANTLING, REPLACEMENT AND REASSEMBLY

The most common fault is caused by the directional valve of a dirty, clogged, worn, or even worse incorrectly mounted.

ATTENTION: In the case of dosing anomalies, BEFORE dismantling the hydraulic system (pumphead), verify

the actual conditions of pumphead directional valves (see "Valve verify and/or replacement").

Loading...

Loading...