X9 Series metering pumps Operating manual

Page 36 Copyright © - OBL Metering pumps - All rights reserved File: UT-4336 – Rev.0

GB

- the new set pressure value required

9. OTHER INFORMATION

9.1 FAULTS AND OPERATING PROBLEMS

The tables below are not exhaustive. They contain possible causes and suggested remedy for the most common and recurring faults.

9.1.1

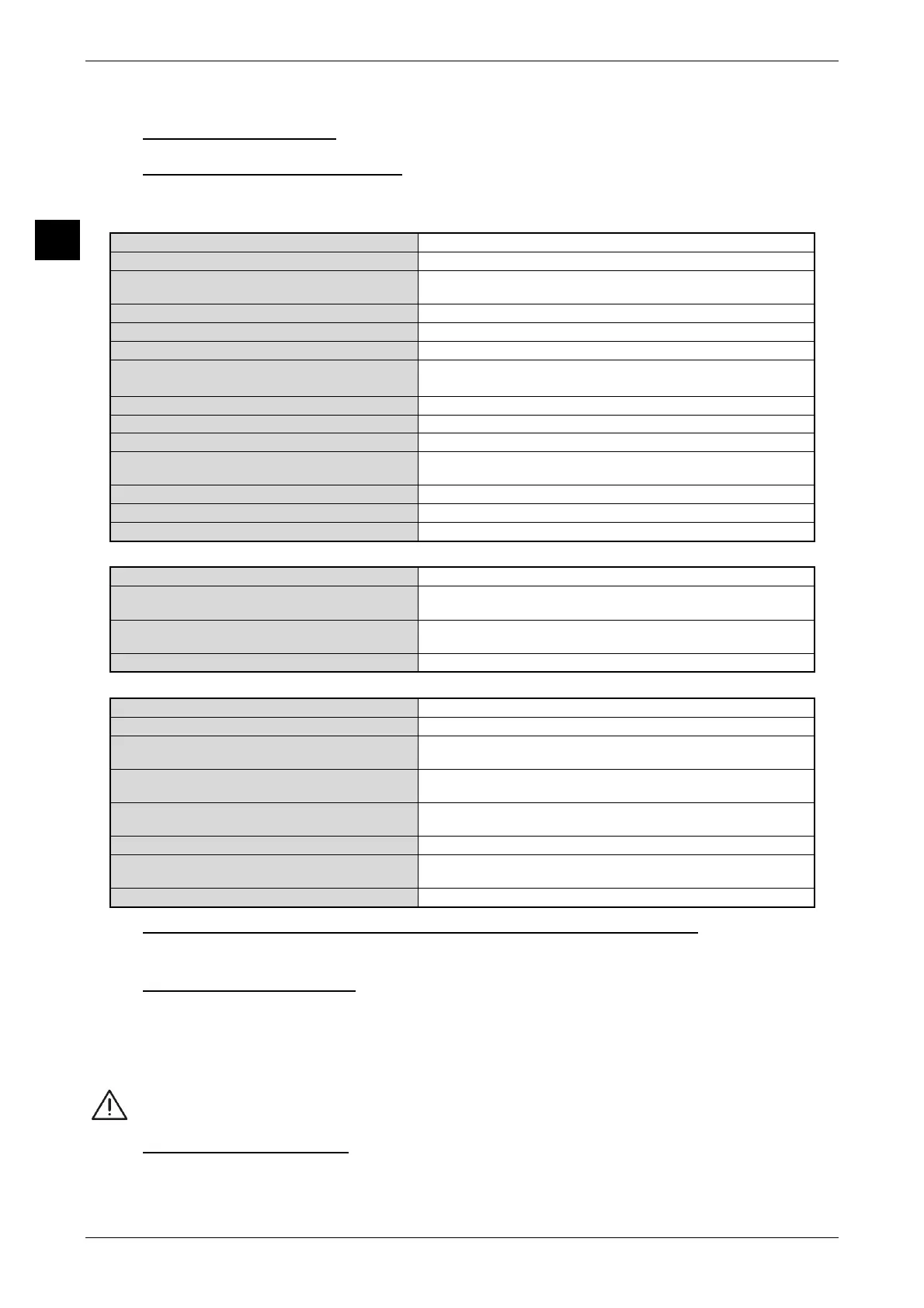

Flowrate lower than expected

POSSIBLE CAUSE REMEDY

- Air enters from suction pipeline fittings - Check suction pipeline and tighten the fittings

- Air trapped inside the pump

- Set, and maintain for a short time, pump flowrate to 100% of

adjustment

- Suction head (suction lift) too high - Reduce the suction head (suction lift)

- Vapour tension too high - Increase the hydrostatic head on suction side

- Pumping temperature too high - Increase the hydrostatic head on suction side

- Handled fluid viscosity too high - Change suction pipeline with one of a larger diameter

- Increase the hydrostatic head on suction side

- Suction tank sealed and/or without vent - Make a vent on top of suction tank

- Suction pipeline clogged or closed by valves - Check suction pipeline and valves

- Filter on suction pipeline clogged - Check and if necessary clean the filter

- Pumps valves dirty, worn or reassembled in wrong

direction

- Check the cleaning, wear and proper direction of assembly of pump

valves

- Safety valve pressure setting is too low - Check if the safety valve opens or not

- Plunger packing damaged - Check for any oil leaks

- Wrong flowrate adjustment setting - Check and if necessary correct the adjustment setting

9.1.2

Flow rate irregular or higher than expected

POSSIBLE CAUSE REMEDY

- Suction pressure higher than discharge pressure

- Increase the discharge pressure at least 0,3÷0,5 bar (3÷5 metres)

respect to the suction pressure

- Backpressure valve stuck in open position because

of dirty or set pressure is too low

- Verify backpressure valve conditions

- Pump valves jammed in open position - Verify pump valves, dismantle and clean them carefully

9.1.3

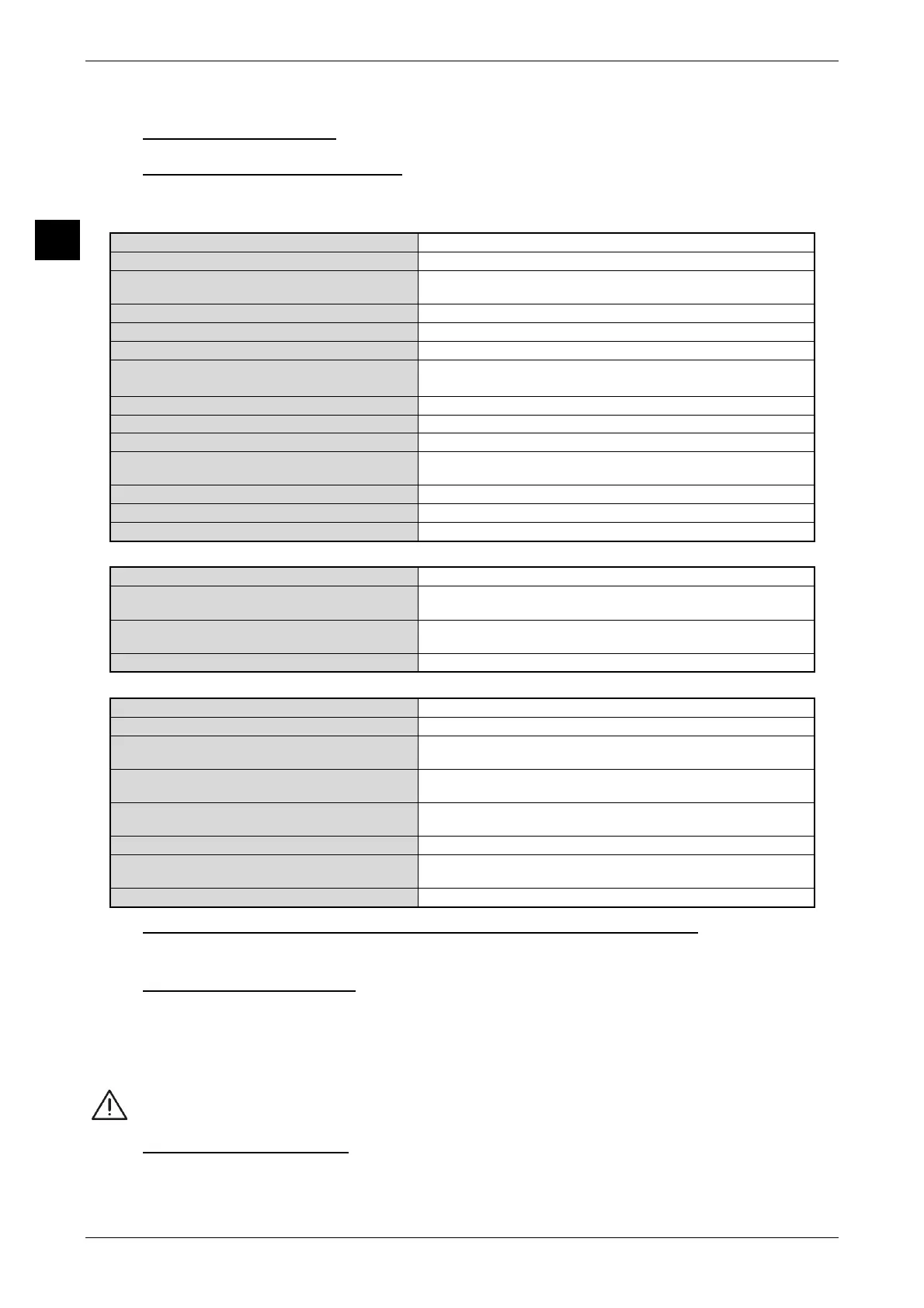

Overheating of pump body and/or motor

POSSIBLE CAUSE REMEDY

- Incorrect electrical connections - Check electrical connections and motor power consumption

- Actual pump working pressure higher than the

maximum allowed

- Install a pressure gauge on the discharge pipeline to verify and

reduce actual pump working pressure

- Discharge pipeline may have reduced section

causing a drastic increase of working pressure

- Reduce the working pressure or install a pulsation damper to

stabilize pressure (avoid the peaks)

- Plant pipelines transmits stress to the pump

connections

- Verify and if necessary correct the pipeline connections to the pump

- Discharge pipeline clogged or valve closed - Check the discharge pipeline

- Backpressure valve set pressure is higher than

maximum allowed

- Check the backpressure valve

- Low level of lubricant oil or chemically contaminated

- Check and if necessary change the lubricant oil

9.2 DISCONNECTION FROM THE PLANT AND SENDING TO OBL FOR MAINTENANCE

BEFORE shipping, always contact OBL customer service and operate as indicated in "Mandatory instruction for returning goods in OBL".

9.3 STORAGE FOR LONG PERIODS

For long term storage (more than 6 months), in addition to those described in "Storage conditions" it is necessary to observe the

following precautions:

- Before storage: protect unpainted surfaces with long-term anti-corrosion products

- Verify the conditions about every 6 months. At the first sign of corrosion clean and re-apply anti-corrosion products

Particular storage conditions should be previously reported, in order to provide a suitable packaging.

9.4 DISPOSAL AND DEMOLITION

The pumps are made of metal and plastic parts.

Loading...

Loading...