Operating manual X9 Series metering pumps

File: UT-4336 – Rev.0 Copyright © - OBL Metering pumps - All rights reserved Page 31

GB

8.2.5

Hydraulic system oil filling

Operations for new hydraulic system oil filling are the same for all types of pumps.

We suggest, however, reference to the following figures during operation:

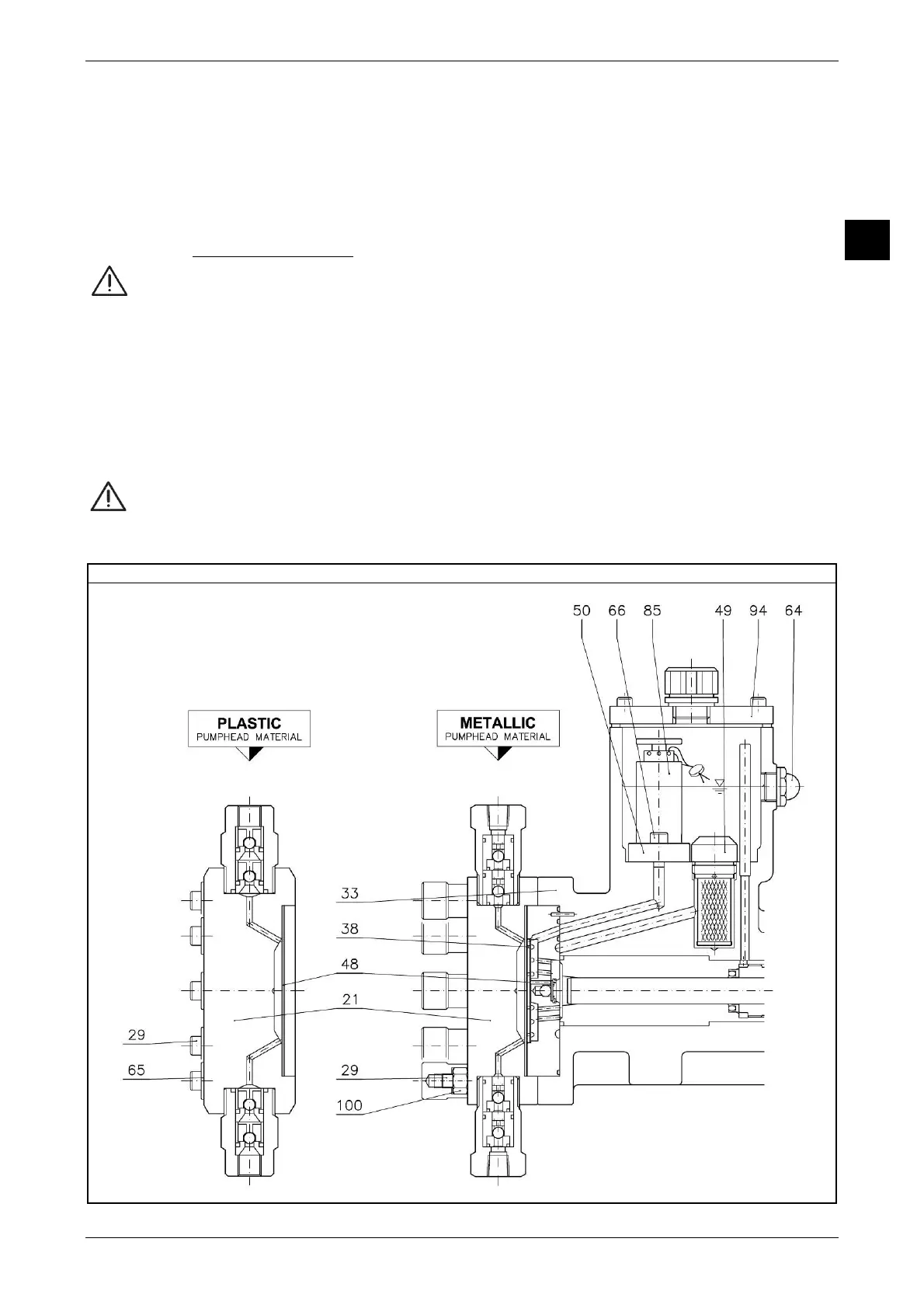

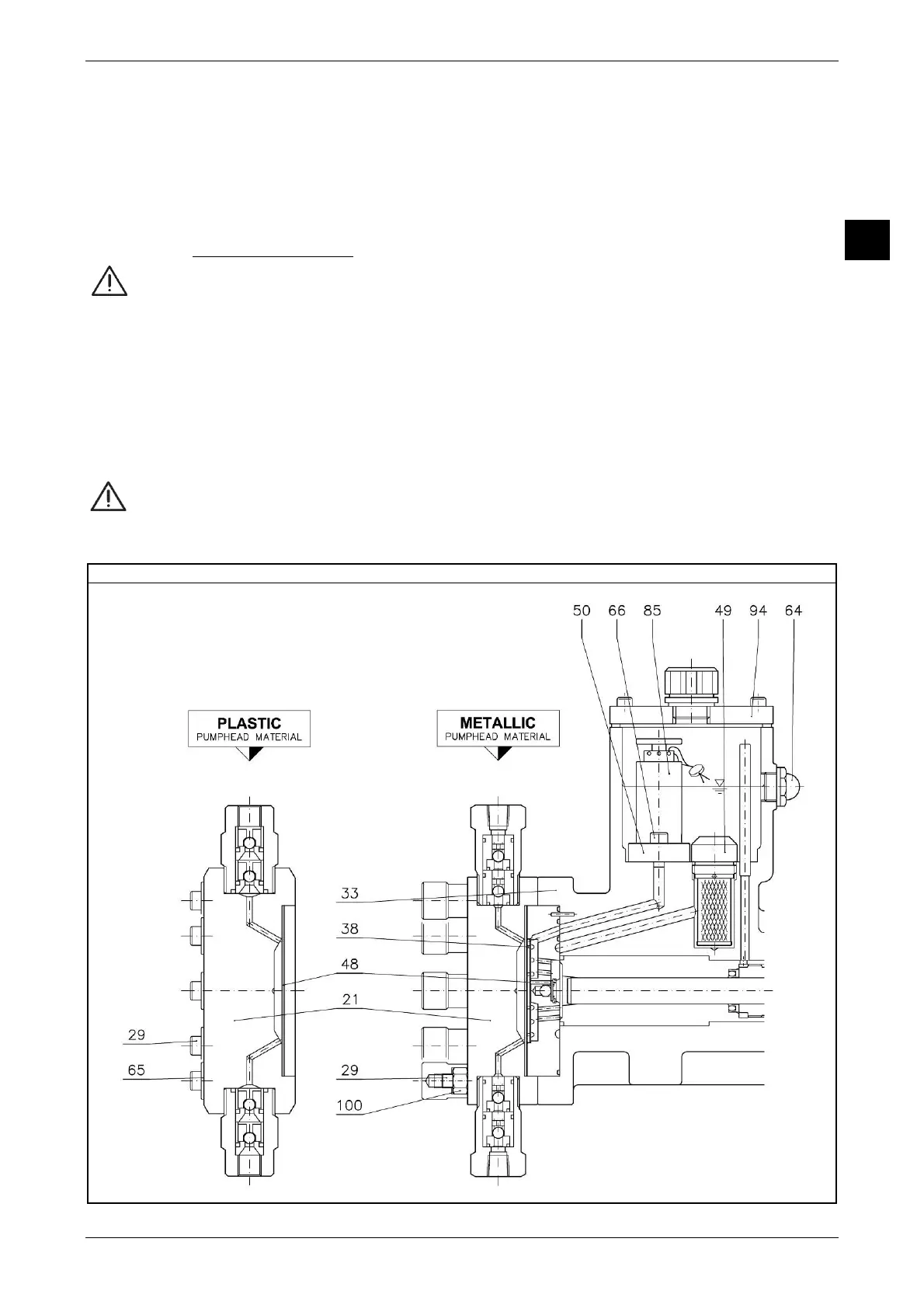

- Pump types LY, LYH: See figure 15 - Pump type LK: See figure 16 - Pump types LN, LP: See figure 17

Proceed as follows:

- remove the tank cover (pos.94), remove the oil filter (pos.49) and clean it without disassembling its components

- unscrew the safety valve locking screws (pos.66) and extract the whole safety valve (pos.85) complete with the locking flange

(pos.50) without breaking the seal. In this way it will be easier to expel air from inside the oil chamber (pos.33)

ATTENTION: The internal safety valve is setted and sealed by OBL at the end of final testing. Do not remove

the seal, do not dismantle the PSV, do not tamper with or, worse, operate directly on the internal components. These

actions could compromise the safety of the plant and of personnel and will also void the guarantee.

- start up the pump with adjustment at 20%. Pour the hydraulic oil in the tank (low viscosity oil 2÷3 °E; see "Hydraulic system

oil replacement") up to the level indicator (pos.64). Passing through the safety valve duct, the oil will fill the oil chamber

(pos.33) and the various ducts, expelling air

- wait in this condition for at least 5 minutes, and in any case until the release of air bubbles stops

- reassemble the oil filter (pos.49), then clean the safety valve (pos.85) tightening the fastening screws (pos.66)

- set the adjustment to 100%, refill oil halfway up the level indicator (pos.64). Reassemble the tank cover (pos.94)

NOTE: Before the pump reaches its optimal functioning, wait until the hydraulic oil (just poured into the oil

chamber) bleeds air from the bleed valve and becomes homogeneous. Depending on the diameter of plunger, pumps

may require from 2 hours (diam. 25÷30) to 8 hours (diam. 10) of operation.

Figure 15 LY, LYH PUMPS: PUMPHEAD

Loading...

Loading...