11

i 1

ije

T.,6

L L A T I 0 N

'.

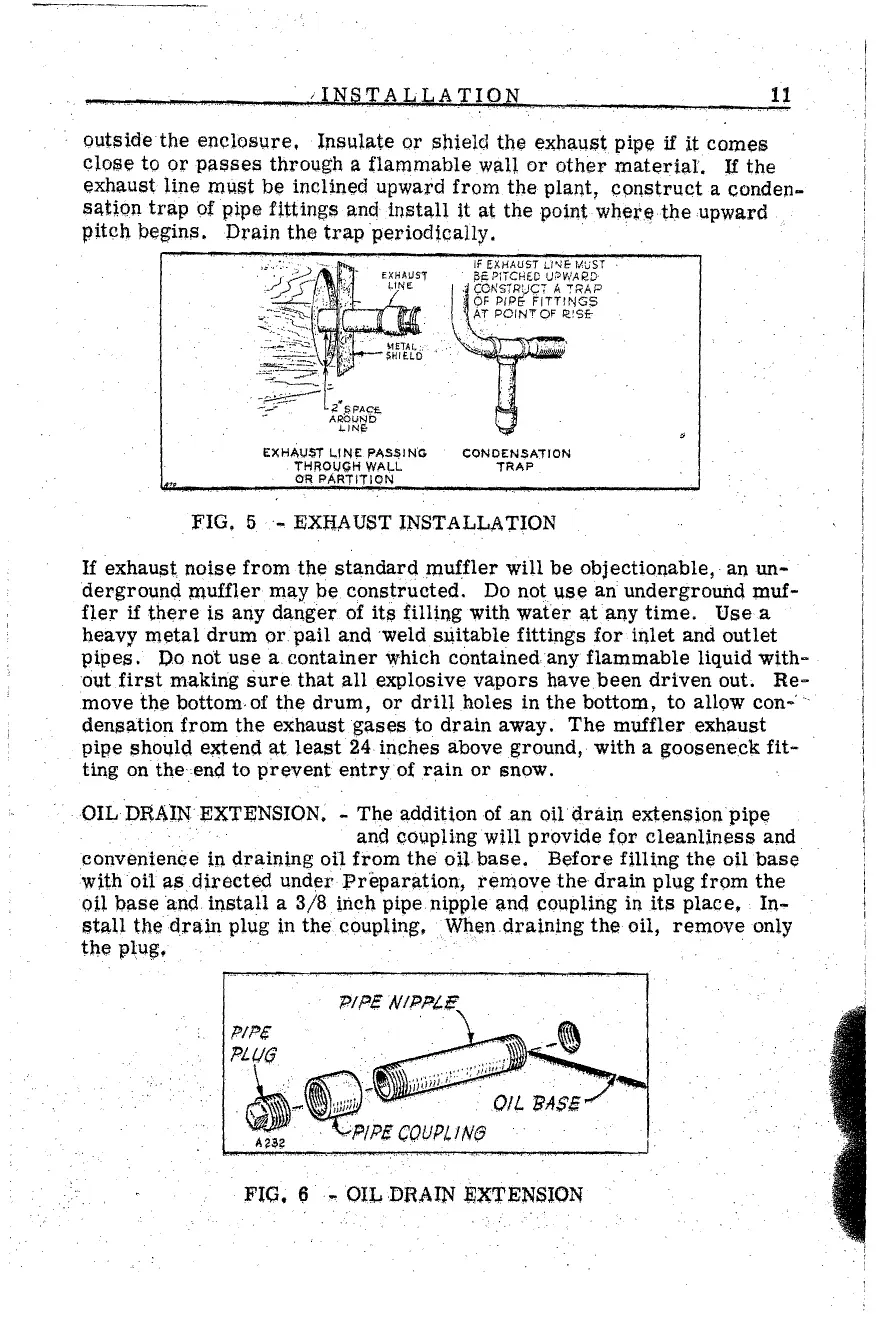

Qutstdethe enclosure. Insulate

or

shield the exhaust pipe

if

it

comes

close

to

or

passes

through a !1ammablewall

or

other

material.

If

the

exhaust line

must be inclined upward from the plant,

construct

a conden-

sation

trap

of pipe fittings and insta,ll it at the point

wherE;j

the

upward

pitch begins.

Drain the

trap

periodically.

.

..

'

If-EXHAUST

j"lE--MUST

:"

p~

PlTCHEe lj,".iWAr2D

,

CONS7RU<:;T

A

,RAP

,

OF

PIPE

FITTINGS

AT

POINT

OF

R?!Sfr

EXHe,l)$T L.IN!': PAS.!iING

CONOtNsATION

THROUGH WA\-L

TRAP

OR

PARTITiON

FIG.

5-

EXHAUST

INSTALLAl'ION

If

exhaust noise from

the

standardrpuffler

will

be

objectionable,' an

un-

dergrounci muffler

ma,y

be

constructed.

Do

not \lSe

an

underground muf-

fler

if

there

is

any danger

of

its

filling with

water

a,t any

time.

Usea

heavy

metal

drum

or.pail

and weld

s~itable

fittings

for

inlet and outlet

pipes.

Do

not

use

a.

container which contained.

any

flammable liquid with-

o\ltfirst

making

sure

that

all

explosive vapors have

been

driven out.

Re-

move the bottom, of the

drum,

or

drill

holes

in

the

bottom, to allow con-'

deU/3ation

from

the

exhaust

gases

to

drain

away.

The

muffler exhaust

pipe

Sho'lj.ld

extend

a,t

least

24 inches

aboveground,

with a gooseneck

fit-

ting

on

the, end

to

prevent

entry

of

rain

or

snow. '

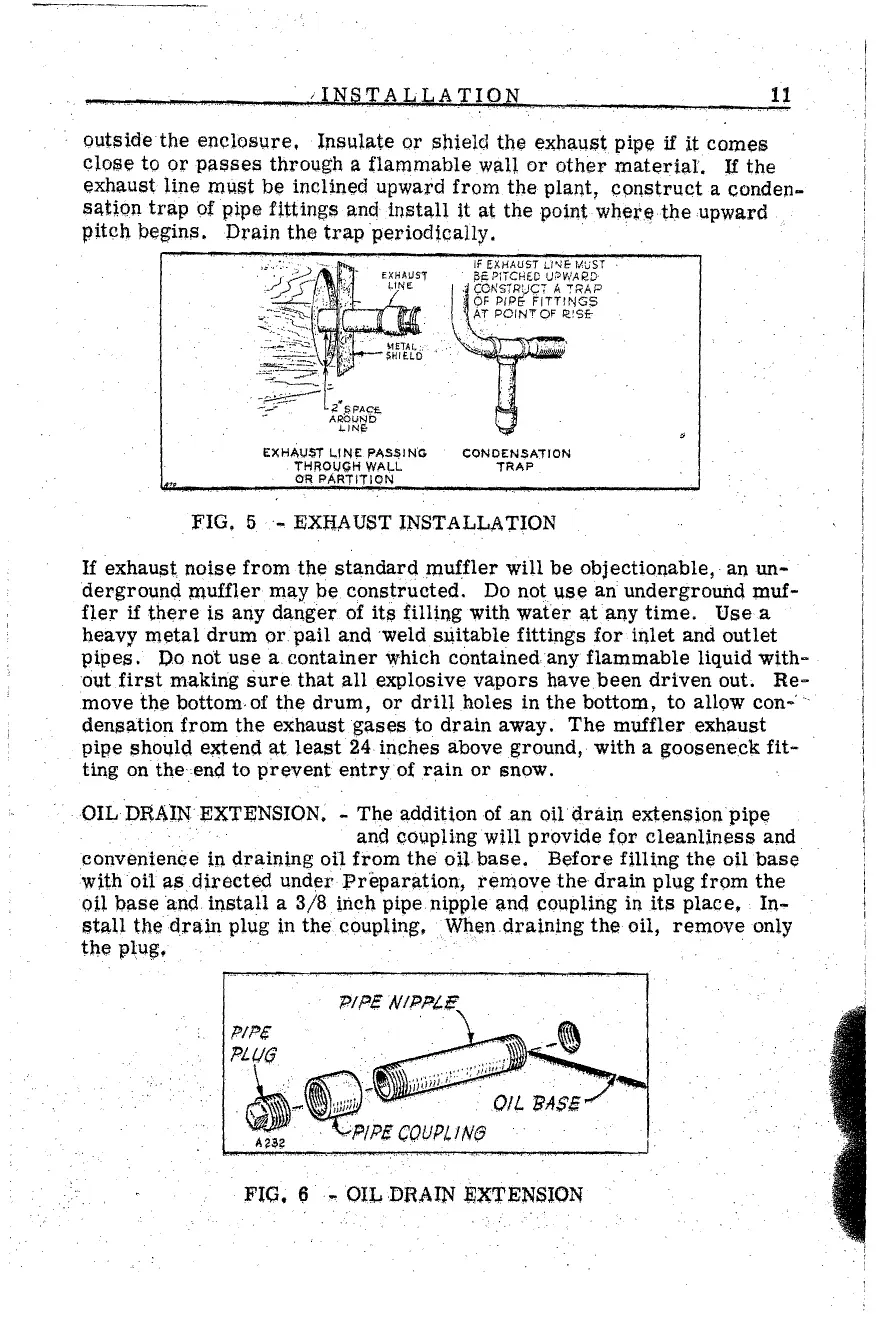

OIL DFtAINEXTENSION. - The addiUon

of

an

oil

drain

e:xl:enSionpipe

. andco\,lpl!ngwill provide

for cleanUness and

convenience in draining oil

from

the

oil

base.

Before

fHUng

the oil

base

wjthoil

as.

<:lj.reeted

under

Preparation,

remove

the

dra,in plug from

the

oil

base

and install a

3/8

inch pipe nipple and coupling in

it/3

place.

In-

atall the

drain

plug in

thecoupllng.

Whendl'aining

the

oil, remove only

the

p\ug. .

FlO. (i .. OILDRAIN

lllXTENSION

Loading...

Loading...