ADJUSTMENTS

naLsprtng

tension.

If

there

isadrop.

in

the frequency,

increase

the,

booster

Internal

spring

tension. To

increase

the

tension,

pullout

on

the

spring

bracket,

and move the pIn

to

a

different

hole.

With

the

,booster disconnected, a maximum drop

of

3.

cycles

from

no load

to,£un load

is

normal.

With

the

booster in operation a maximum IN

...

C~E,ASE

of 2

cycles

from

no load

to

full load

is

normal.

A drop of 1 '

,cycle

at

1/4

load

is

permissible,

giving an over

all

spread

of

3

cycles,

ma:ximum. '

.

The.effectofthe

booster

is

limited by

the

,

general

condition

of

the

engine.

The

booster

can not compensate for a

loss

in engine vacuum caused by

leaky valves,

wornpiston

rings,

etc,

The,

..

boosterrequires

little

maintenance

other

than using a fine,

wire

to

clean

the

small

hole in

the

short

Vacuum tube which

fits

into

the

hole

in

.

thetop.of

the

engine intake manifold.

Do

not

enlarge

this

hole.

If

there'

is'tensicm on

the'

external

spring, when the plant is' operating

at

no

load

or

light

load,it

maybe

due

to

improper

adjustment;

restrictedho},ein

the

small

vacuum

tube,

or

a

leak

in

the

booster

diaphragm

or

gasket.

'.

'

'-

.:,\".,.::-,

,'._.'..;,;,

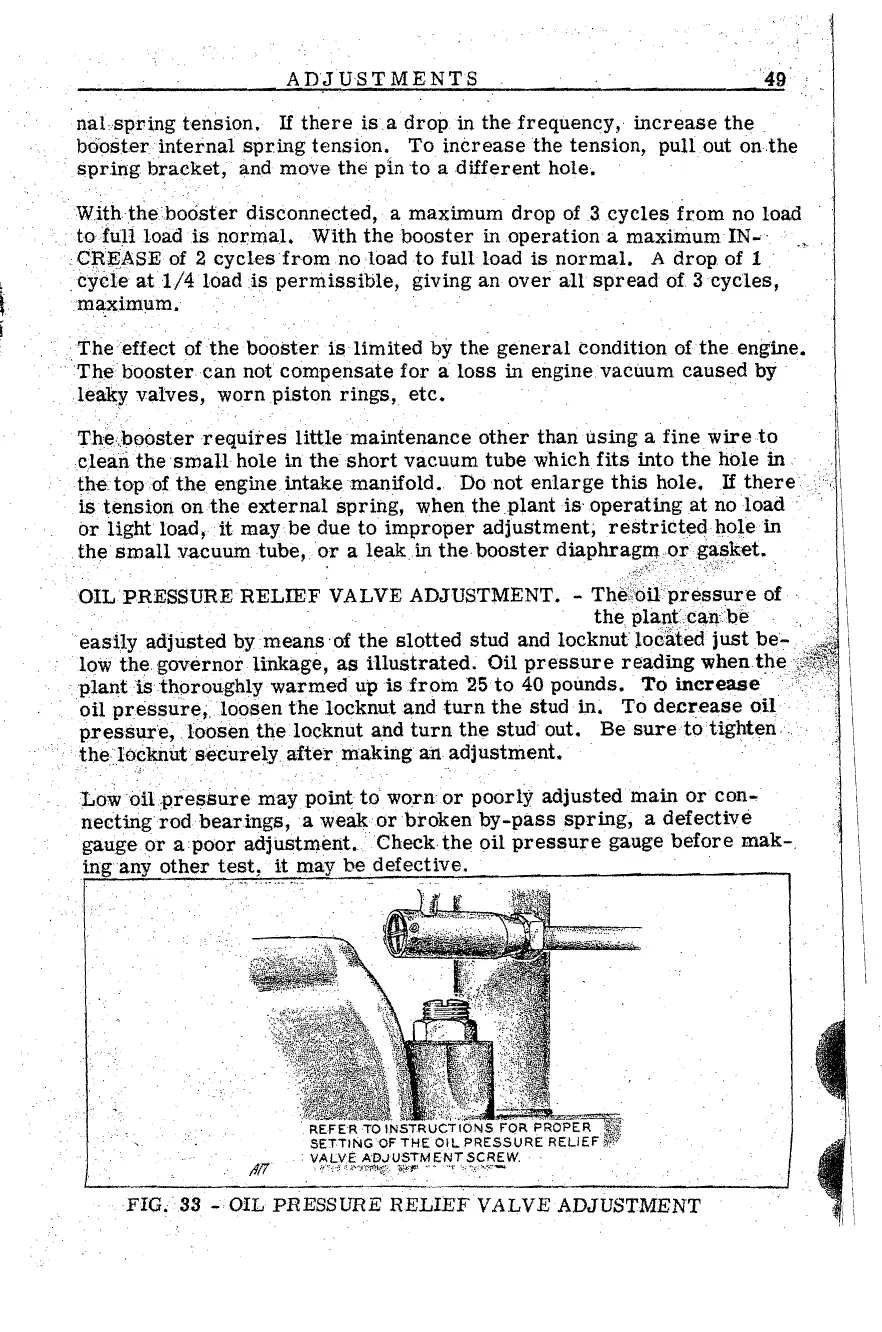

OILPRESSURERELIEF

VALVE ADJUSTMENT. -

Th~r()UPtessur,e

of

the,

plalltcallbe

.

easily adjusted by means 'of

the

slotted stud and

locknutlonaied

just

be-

low

the

governor Unkage,

as

illustrated,

Oil

pressure

reading when

the

'"

plantlsthoroughlywarmedupisfrom

25

to

40

pounds. To

increase'

,

oil

pressure;"loosen

the

locknut and

turn

the

stud in. To

decrease

oil

pressure,

loosen

the

,locknut and

turn

the

stud out. Be

sure

to

tighten,

the,Jockmitsecu:re~y

after, making

art

adjustment.

Lo~oiLpres:sure

may point

to

worn

or

poorly adjusted

main

or

con-

neclingrodbearlngs,a

weak

or

broken

by-pass

spring,

a defective

gauge

or

a poor adjustment. Check

the

oil

pressure

gauge

before

mak-,

ingany

other

test,

it

may be

defective.

FIG.SS

-OIL

PRESSURE

RELIEF

VALVE ADJUSTMENT

Loading...

Loading...