5 Installation

−15−

Unit

model

Nominal

thread size

Tightening

torque

BLH230

BLH450

M2.6

0.4 N·m

(3.5 lb-in)

BLH5100 M3

0.6 N·m

(5.3 lb-in)

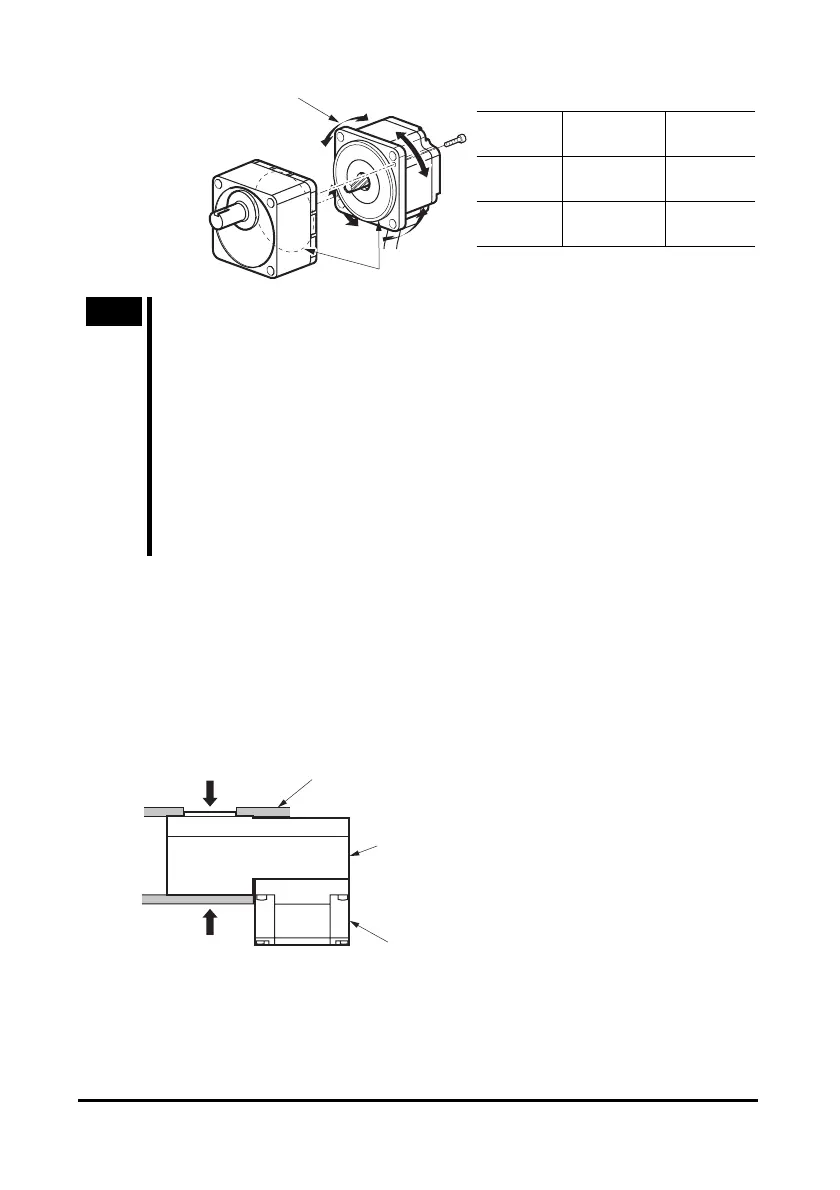

Pilot

Change the cable

position to a desired

90° direction.

Note

• Do not forcibly assemble the motor and gearhead. Also, do not let metal

objects or other foreign matters enter the gearhead. The pinion or gear of

the motor output shaft may be damaged, resulting in noise or shorter service

life.

• Do not allow dust to attach to the pilot sections of the motor and gearhead.

Also, assemble the motor and gearhead carefully by not pinching the O-ring

at the motor’s pilot section. If the O-ring is crushed or severed, grease may

leak from the gearhead.

• The hexagonal socket head screws (2 pcs.) assembling the motor and

gearhead are affixing the motor and gearhead only temporarily. When

installing the gearhead, be sure to use the supplied four hexagonal socket

head screws.

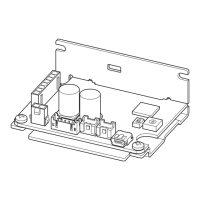

5.3 Installing the combination type hollow shaft flat

gearhead

A gearhead can be installed by using either its front or rear side as the mounting

surface. Install the supplied hexagonal socket head screw in the four mounting holes

you opened and tighten the nuts until no gaps remain between the motor and

mounting plate. Also, attach the supplied safety cover to the hollow output shaft on

the end opposite from the one where the load shaft is installed.

Front

Mounting plate

Gearhead

Motor

Rear

Loading...

Loading...