6 Connection

−29−

6 Connection

The following shows the method of connecting the motor and driver, power supply,

external potentiometer, earth connection method, an example of connection and I/O

signals.

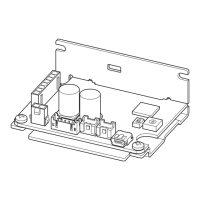

6.1 Motor and driver connection

Insert the motor cable connector into the motor connector of the driver.

Unit model Motor connector

BLH015, BLH230, BLH450 CN3

BLH5100 CN3, CN4

Note

• Firmly insert the connector in position. Incomplete connection of the

connector may cause operation failure, or may damage the motor or driver.

• Do not push or pull the cable. Handle only the plastic connector instead.

Do not apply force in any direction other than that in which the connector is

inserted or pulled out. Improper application of force may damage the

connector and driver.

When extending the motor cable, use the accessory extension cable. The maximum

extension distance including the cable length of the motor itself should be 2 m

(6.6 ft.).

6.2 Connecting the power supply

Input power supply voltage is 24 VDC ±10%.

Insert the power supply cable connector into the driver power supply connector

(CN1). The specific connections vary depending on the outputs. If the supplied

power supply cable is not used, use a cable of the applicable wire size shown in the

table below.

Unit model Power supply cable size

BLH015, BLH230, BLH450 AWG22 (0.3 mm

2

) or more

BLH5100 AWG18 (0.75 mm

2

) or more

Note

• Sufficient care must be taken not to mistake the power supply polarity.

Connection with incorrect polarity may damage the driver.

• Do not route the driver power supply cable in the same conduit with other

power supply lines or motor cables.

• When you want to turn on the power supply again or pull out the motor cable

connector, do so 5 s or more after power supply has been turned off.

Loading...

Loading...