Operating Instructions

COMPAX-M / -S

RS232 interface

160

8.6.3 RS232 interface

You can communicate with COMPAX via an RS232 interface on a PC. The

following functions are available.

♦

Direct command input and execution in on-line mode.

♦

Read status values.

♦

Read and write program data records (the complete stock of commands is

available here).

♦

Read and write (password protected) parameters.

♦

Transmit control instructions.

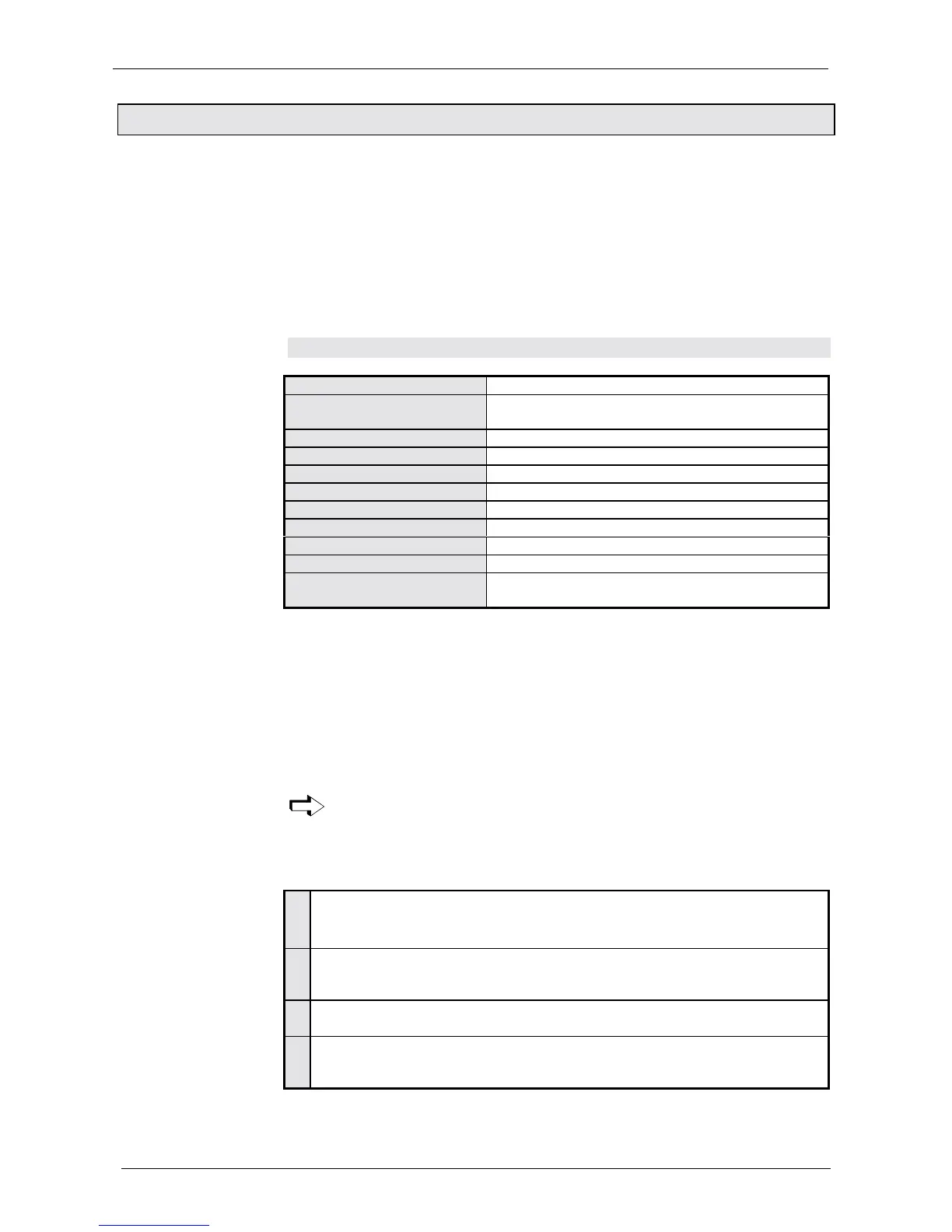

8.6.3.1 Interface description

Interface RS 232

Baud rate: 9600* or 4800 (selected with P19)

COMPAX 1000SL: fixed setting 9600

Word length: 8 bit

Stop bit: 1

Parity: none

Hardware handshake: yes (RTS,CTS)

Software handshake: XON, XOFF (can be selected using P20)

Entry buffer: error string, max. 30 characters

Output buffer: status string, max. 30 characters

Data format: ASCII

End sign: C

R

(carriage return) or C

R

L

F

(carriage return, line

feed)

* Default setting; simultaneously press the three front plate buttons while switching

on to set COMPAX to 9600 Baud.

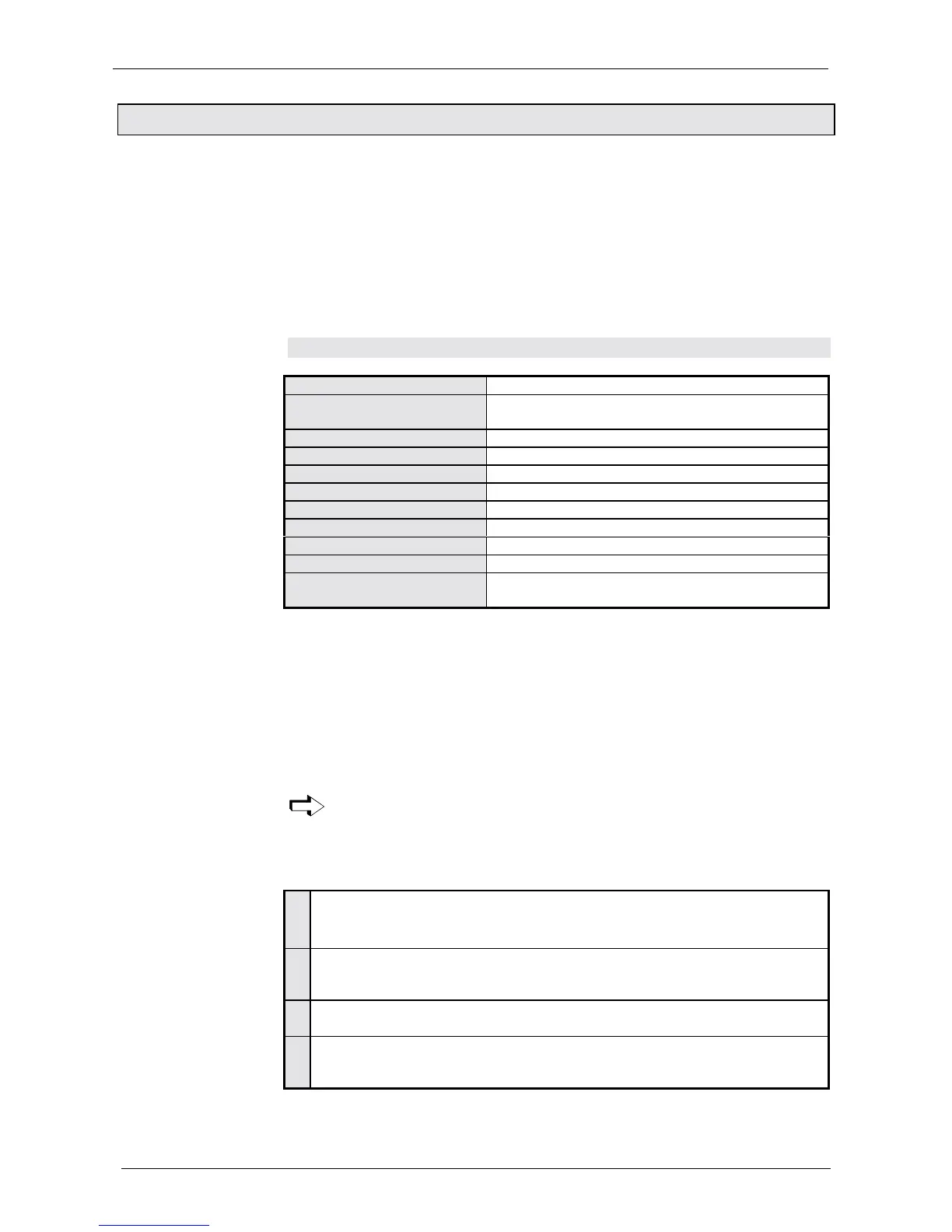

♦

all displayable ASCII characters

♦

any inserted spaces

♦

a function sign, if nec. ($, ?, !)

♦

C

R

(carriage return) for storing the command in the intermediate memory. If no

function signs have been transmitted, the command is accepted and executed if

necessary (see next page).

♦

L

F

(line feed) has no meaning to COMPAX

COMPAX only receives a command if a previously transmitted command

was answered with C

R

L

F

>.

♦

if the syntax is error-free with C

R

L

F

> or the required response and C

R

L

F

>

♦

if there are errors, depending on the contents of P20

$

Automatic "Position reached" message

1. only applies to POSA and POSR

2. COMPAX transmits: $

C

R

L

F

> when the position is reached.

,

Interpreting and storing commands

COMPAX stores the instruction in the intermediate memory (capacity: one

instruction) without executing it.

?

Echo

COMPAX sends the data received with C

R

L

F

>.

!

Executing commands

Whenever a "!" occurs, the instruction is executed from the intermediate

memory.

These function signs can be attached to any instruction.

Example: POSA 100 $ C

R

L

F

COMPAX moves and responds once position 100 is reached with: $

C

R

L

F

>

Interface

parameters

COMPAX receives

COMPAX

responds:

Meaning of

function signs

Loading...

Loading...