4

SUPERFLO® VST, SUPERFLO

®

VS and SUPERMAX® VS Variable Speed Pumps Installation and User’s Guide

Grounding

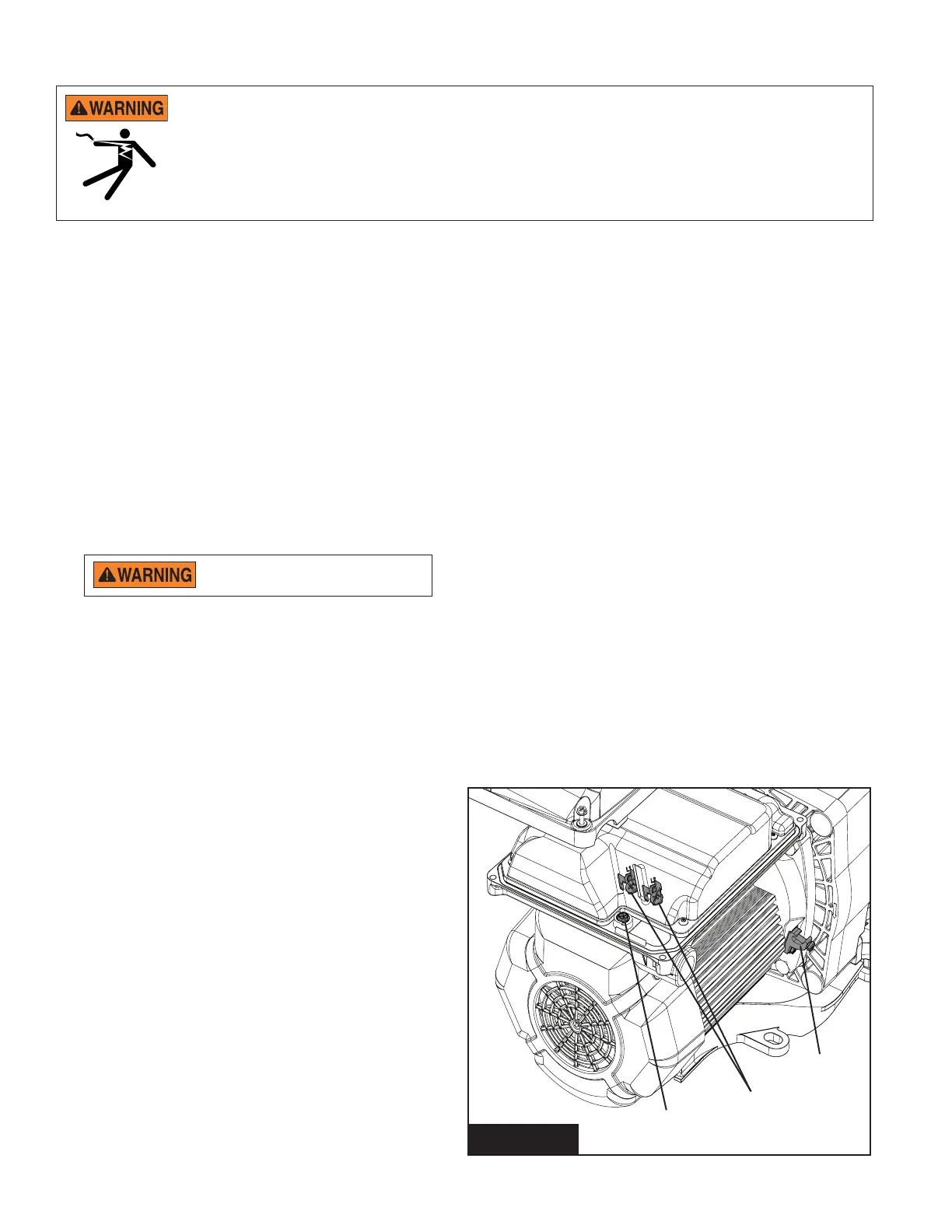

1. Permanently ground the motor using the Grounding

Terminal (Figure 3) inside the drive wiring

compartment. Refer to the current National Electrical

Code and any local codes for wire size and type

requirements. Ensure the ground wire is connected to

an electrical service ground.

2. ONLY connect the pump to a supply circuit protected

by a ground-fault circuit-interrupter (GFCI) circuit

breaker.

Note: Pentair oers a 2-Pole 20 Amp GFCI breaker

(P/N PA220GF).

Note: The pump should be wired to its own

independent circuit unless the pump is operated in

tandem with a Pentair salt chlorine generator.

Bonding

1. Using the Bonding Lug located on the side of the

motor (Figure 3), bond the motor to all metal parts of

the pool structure, electrical equipment, metal conduit

and metal piping within 5 ft. (1.5 m) of the inside walls

of the swimming pool, spa or hot tub in accordance

with the current National Electrical Code and any local

codes.

2. Solid copper bonding conductor of 8 AWG or larger is

required. For Canadian installations, 6 AWG or larger

solid copper bonding conductor is required.

The pump accepts 115-230 V, 50 or 60 Hz single

phase input power. Power Connections (Figure 3) are

capable of handling up to 10 AWG solid or stranded

wire.

The motor controller will automatically regulate the

pump speed when running on lower voltage to keep

current below 13.6 A. No wiring change is required

to run the pump on 115 V nominal power, the same

terminals are used as with high voltage wiring.

The drive will operate on 2-Phase Line-Line-Ground

electrical systems as well as Line-Neutral-Ground

systems.

Wiring

1. Ensure all electrical breakers and switches are

turned o before wiring the motor.

STORED CHARGE - Wait at least 5

minutes before servicing.

2. Ensure supply voltage meets the requirements

listed on the motor nameplate.

3. For wiring sizes and general requirements, follow

specications dened by the current National

Electric Code and any local codes. When in doubt

use a heavier gauge (larger diameter) wire.

4. Ensure all electrical connections are clean and

tight.

5. Cut all wiring to the appropriate length so they do

not overlap or touch when connected to terminals.

6. ALWAYS reinstall the drive lid after electrical

installation or before leaving the pump

unsupervised during servicing. This will prevent

rainwater, dust or other foreign matter from

accumulating in the drive.

Note: Ensure wires are not pinched between the

drive body and lid.

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION. The pump must be installed by a licensed or certied electrician or a qualied

service professional in accordance with the National Electrical Code and all applicable local codes and ordinances. Improper installation

will create an electrical hazard which could result in death or serious injury to users, installers, or others due to electrical shock, and may

also cause damage to property.

Always disconnect power to the pump at the circuit breaker before servicing the pump. Failure to do so could result in death or

serious injury to service people, pool users or others due to electric shock and/or property damage.

Read all servicing instructions before working on the pump.

Figure 3

Bonding

Lug

Power

Connections

Grounding

Terminal

Electrical Installation

Loading...

Loading...