SUPERFLO® VST, SUPERFLO

®

VS and SUPERMAX® VS Variable Speed Pumps Installation and User’s Guide

5

External Control via RS-485

The following instructions only apply to SuperFlo

®

VST and SuperMax

®

VS pumps manufactured after

10/15/20. For all other pumps, refer to External

Control via Digital Inputs on page 6.

These pumps can be controlled from certain Pentair

control systems, via an RS-485 signal, when paired with

the RS-485 Automation Wiring Kit (P/N 356324Z - Black).

Note: IntelliConnect

®

Control and Monitoring

Systems can NOT externally control this pump via

RS-485. The pump will need to be connected via

digital inputs. Refer to External Control via Digital

Inputs on page 6.

Note: If the pump is manually stopped using the

Start/Stop button, the pump will not run until the

Start/Stop button is pressed. If the Start/Stop

LED is illuminated, the pump is active and can be

controlled externally.

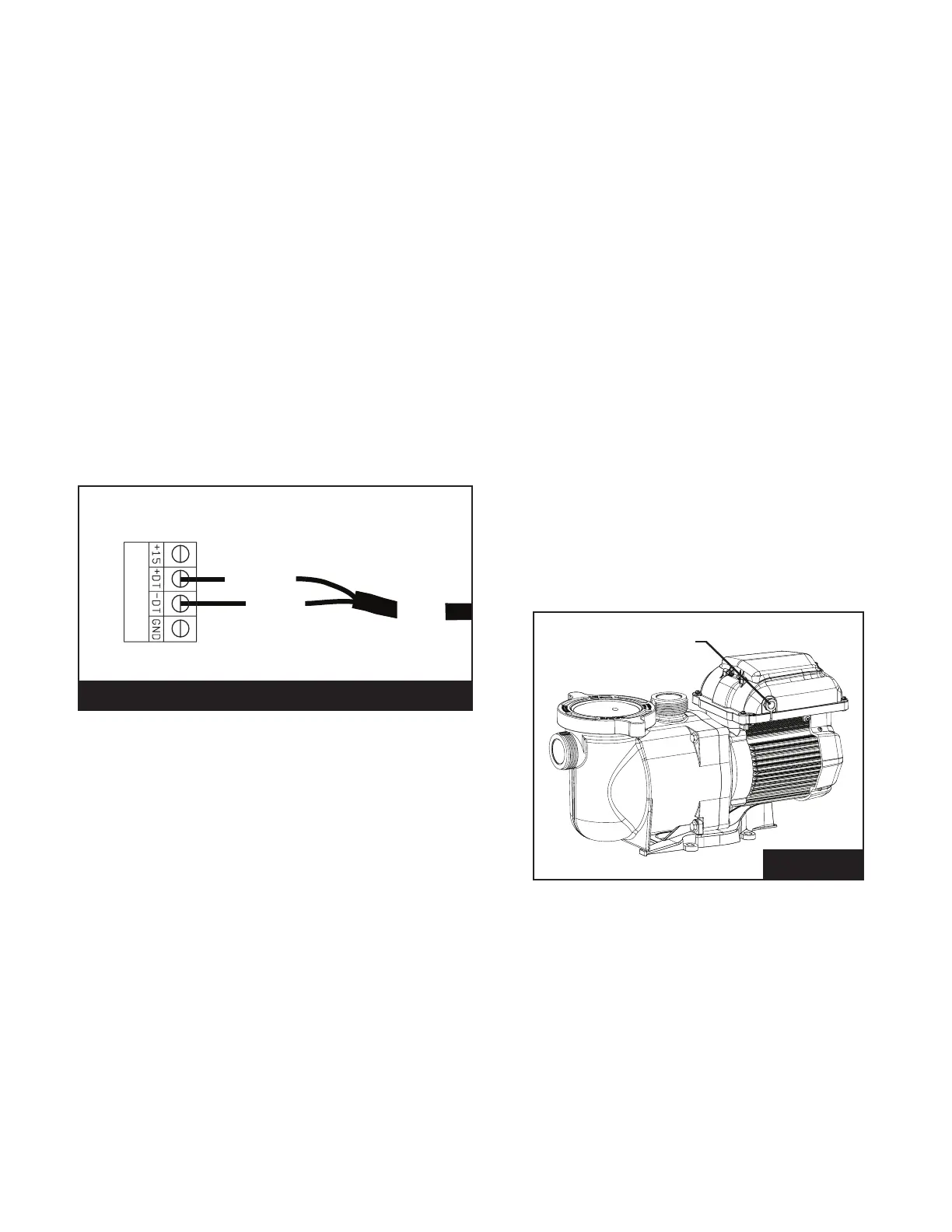

Only the GREEN and YELLOW conductors will be used

to wire the pump for external control via RS-485. See

Figure 4.

Control System Pump Settings

Pump Type: Variable Speed (VS)

Control systems with older rmware may require the

pump be designated "IntelliFlo VS".

This pump will not process control system commands

if designated a Variable Flow (VF) or Variable Speed/

Flow (VSF) pump.

Pump Address: 1 or 2

Ensure the assigned pump address matches the pump

address in the control system. Refer Setting the Clock

and Pump Address, page 8.

Refer to the control system manual for more information

on connecting and programming your pump.

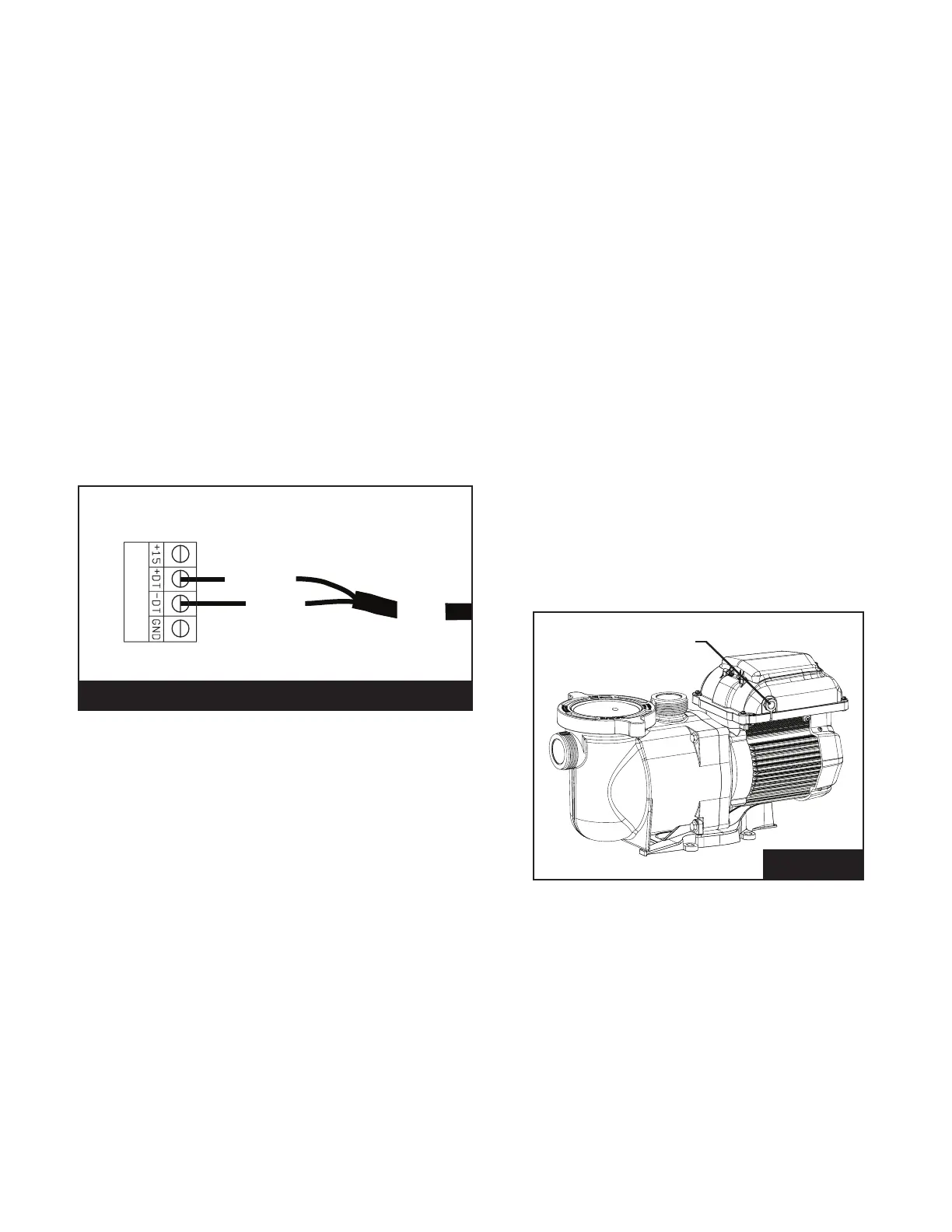

Pump Com

Port

Figure 5

TO WIRE FOR EXTERNAL CONTROL USING RS-485:

1. Route the communication cable from the Pump

Com Port (Figure 5) to the control system wiring

compartment.

2. Ensure the cable reaches all necessary terminals

and cut to the necessary length.

3. Strip the cable 3/4" (19 mm).

4. Strip the 24 AWG GREEN and YELLOW conductors

1/2" (13 mm).

5. Cut back and terminate unused conductors

according to local and national electrical codes.

6. Connect YELLOW and GREEN conductors to the

control system as shown in Figure 4.

7. Program the pump's internal clock. Refer to Setting

the Clock and Pump Address on page 8.

8. Program SPEED 1 to a speed of 0 RPM and

duration of 24 hours. Refer to Programming Custom

Schedules on page 9.

9. Disable priming at the pump. Priming duration and

speeds will be controlled by the control system.

Note: If priming is not disabled at the pump,

priming will be continue to be controlled by the

pump. Refer to Priming on page 11.

10. Plug the communication cable into the Pump Com

Port (Figure 5).

YELLOW

GREEN

Automation System

COM Port

Note: Only the GREEN and

YELLOW wires will be used. All

other wires should be cut off at the

cable sheath.

From

Pump

4

3

2

1

Figure 4

RS-485 Automation Kit (P/N 356324Z - Black)

Loading...

Loading...