8

104 73 15-26

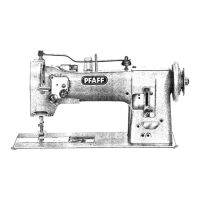

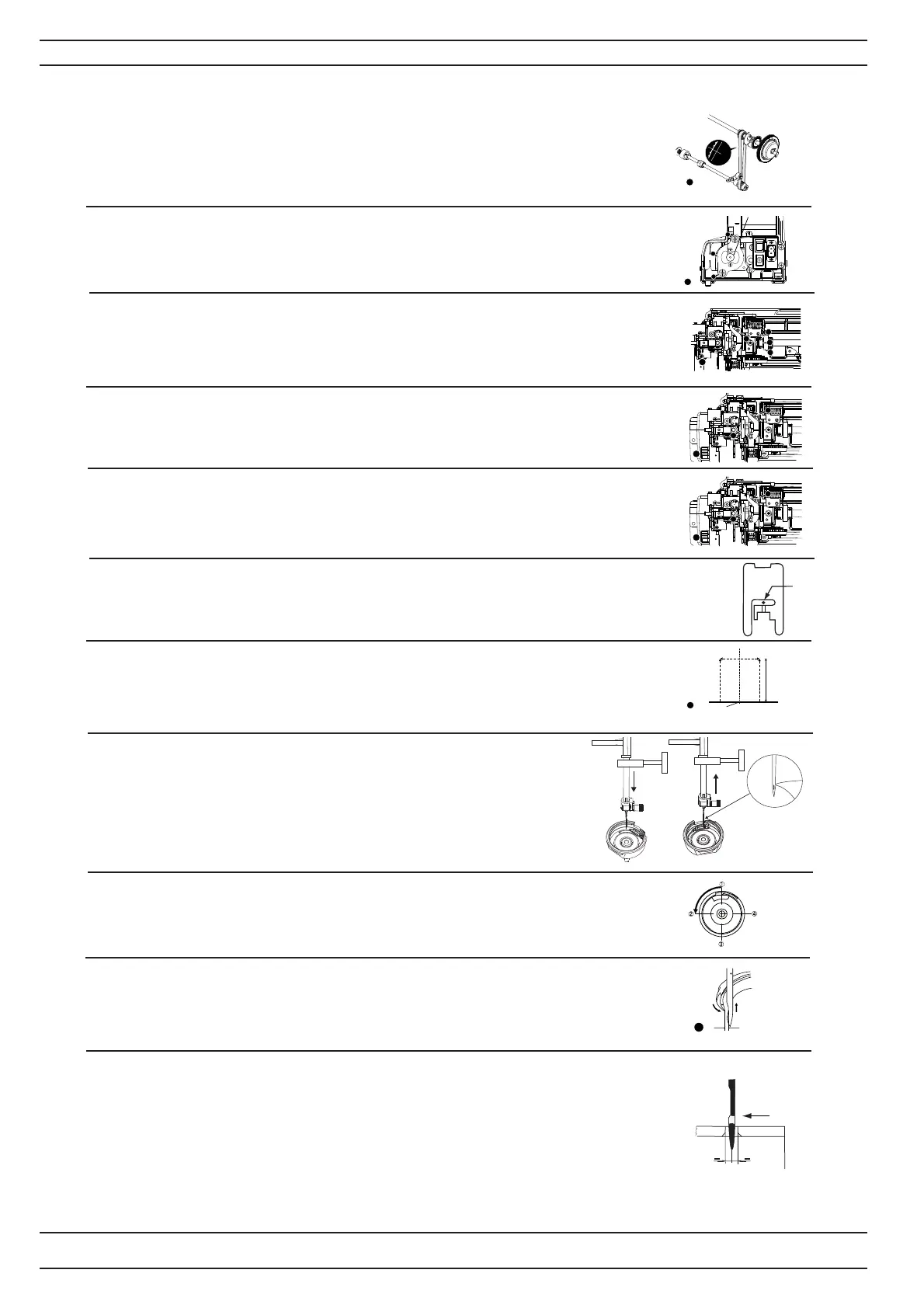

10. The gap between the needle and the hook

The gap should be as small as possible, but max 0.15 mm - Straight stitch 2.5

mm.

11. Setting the needle plate (the hook cover) in relation to the needle in the feeding

direction.

The needle should, in the feeding direction, descend right into the middle of the

needle hole of the needle plate.

9. The play of the hook gear

It is impossible to obtain an equally large play in one rotation of the cog wheel,

but it should be as small as possible at the tightest spot during the revolution.

2. Belt tension, motor belt

Move the motor unit (b) util a correct belt tension is obtained.

Settings - Quick reference

1. Belt tension, drive belt

The belt tension shall be adjusted by re-position tensioning roller by push

it up or down until it is a fi rm belt tension.

Settings - Quick reference

6. Setting the needle in centre position

The needle should always get to the centre position, when the main switch is turned.

3 Upper shaft axial play

No lateral play between main shaft collar and bushing and main shaft should

rotates smoothly. Screws (a, b) used for adjustment.

8. The timing of the hook in relation to the needle

When the needle is in its centre position and the needle is

moving upwards, the tip of the hook should pass behind the

centre of the needle, when the needle is 2.3 mm above its lower

turning position.

4. Take up lever

When turning the hand wheel no noise should appear in the thread take up lever.

5. Timing of the Feeding in relation to the needle

When is in its needle lowest point.The feed lifting rock cam (a) and the screw (b)

of feed rock cam (c) should now be parallel.

7. Zigzag movement of the needle adjustment

On Zig-zag 4x7 mm and while urn the hand wheel to move the needle bar

upward. The vertical distance in which the needle point goes up until it swings

over to the right side should be 6.0~6.2mm.

1

3~4m/m

2

b

d

c

a

b

1

d

c

a

b

1

a

b

1

1

Needle plate

6.0-6.2mm

1

0.05~0.1 mm

Loading...

Loading...