*** Apply a preliminary torque of 7 N·m in a crossed sequence. - Tighten by 90° in a crossed sequence. - Tighten again by 90°

in a crossed sequence.

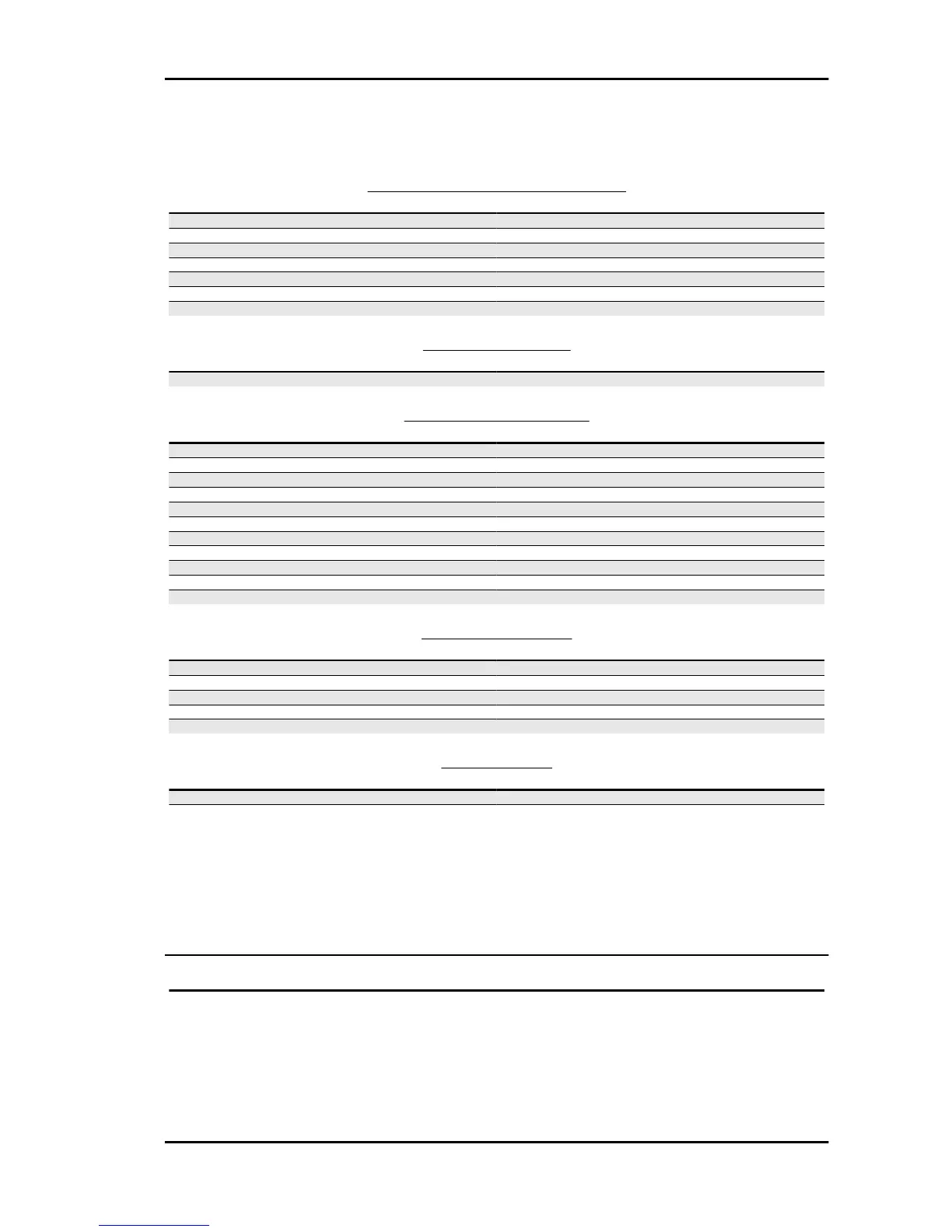

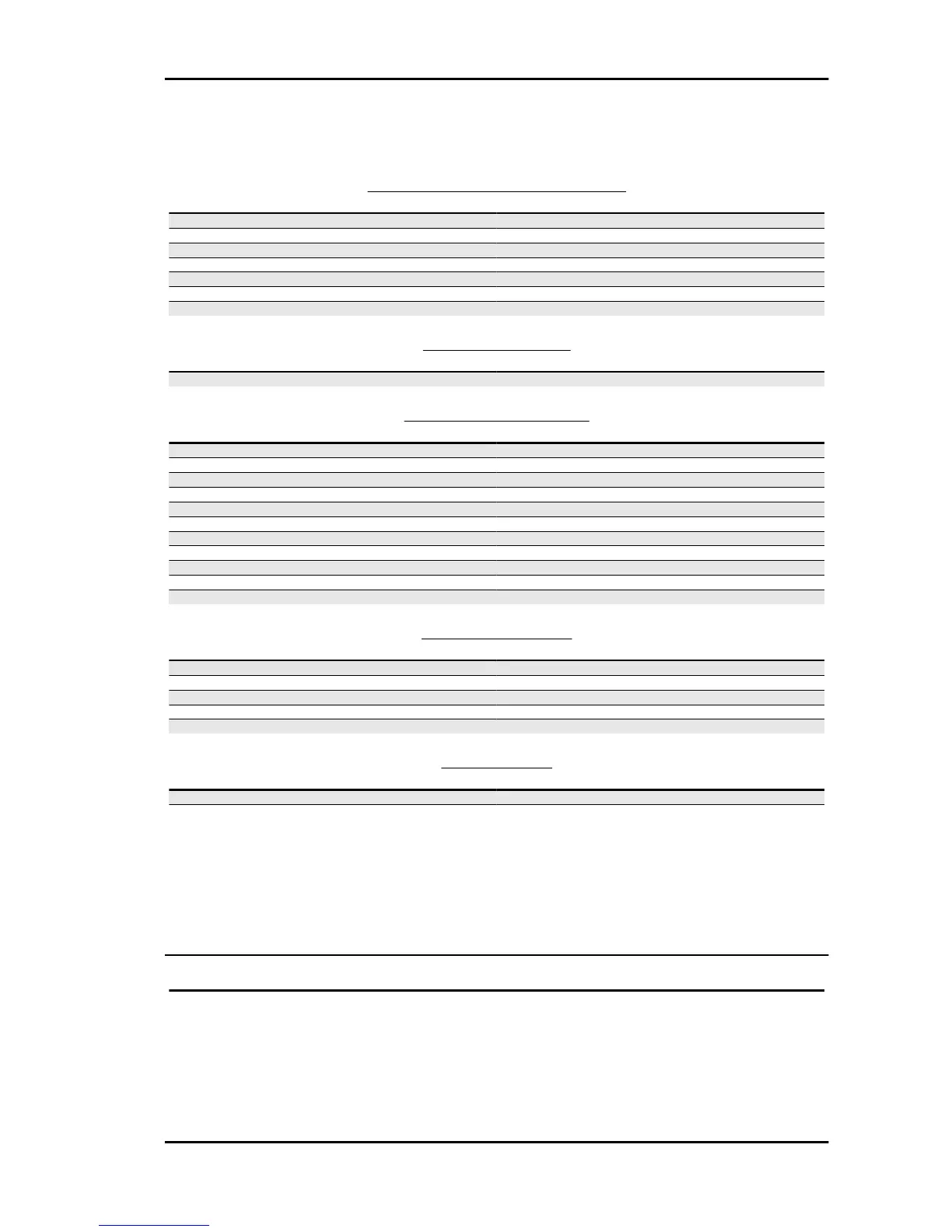

CRANKCASE AND CRANKSHAFT

Name Torque in Nm

Countershaft fixing nut 25 ÷ 29

Engine oil filter 12 - 16

Engine oil drainage plug 24 to 30

Engine-crankcase coupling screws 11 to 13

Oil pump screws 5 to 6

Gear mounting on crankshaft screws 10 -12

Bulkhead screws for oil pump housing cover 8 - 10

FINAL REDUCTION

Name Torque in Nm

Rear hub cover screws 24 ÷ 27

TRANSMISSION COVER

Name Torque in Nm

Driven pulley nut 92 - 100

Drive pulley nut 160 - 175

Anti-vibration roller screw 16.7 ÷ 19.6

M8 retainers for transmission cover 23 ÷ 26

M6 retainer 11 ÷ 13

Anti-vibration roller retainer 17 - 19

Clutch ring nut 65 - 75

Air conveyor unit screws 7 9 N

Water pump cover screws 3 ÷ 4

External transmission cover screws 7 ÷ 9

Flywheel cover screws 11 - 13

FLYWHEEL COVER

Name

Torque in Nm

Flywheel fixing nut 115 - 125

Stator retainers 8 - 10

Blow-by recovery duct fixing screws 3 - 4

Screw fixing freewheel to flywheel 13 - 15

Stator cable harness guide bracket screws 3 - 4

LUBRICATION

Name

Torque in Nm

Oil pump cover screws 0.7 - 0.9

Screws fixing oil pump to the crankcase 5 to 6

See also

Fuel tank

Refitting

Overhaul

Refitting

NOTICE OF TECHNICAL SERVICING

Beverly 500 i.e. Characteristics

CHAR - 11

Loading...

Loading...