Refitting the piston rings

- Place the scraper ring spring on the piston.

- Install the scraper ring keeping the opening op-

posed to the spring junction and with the writing

"top" facing the piston crown. The chamfered side

of the oil scraper ring should always be facing the

piston crown.

- Fit the second lining with the identification letter

or the writing "top" facing the piston crown. In any

case, the step must be facing opposite the piston

crown.

- Install the first compression lining in the direction

imposed by the housing.

- It is advisable to use a fitter to facilitate the in-

stallation of the linings.

N.B.

THE TWO PISTON RINGS ARE MADE WITH A TAPERED

CYLINDRICAL CONTACT CROSS-SECTION. THIS IS TO

ACHIEVE A BETTER BEDDING.

- Misalign the lining openings at 120° as shown in the figure.

- Lubricate the components with engine oil.

- The engine uses the first compression lining with an L section.

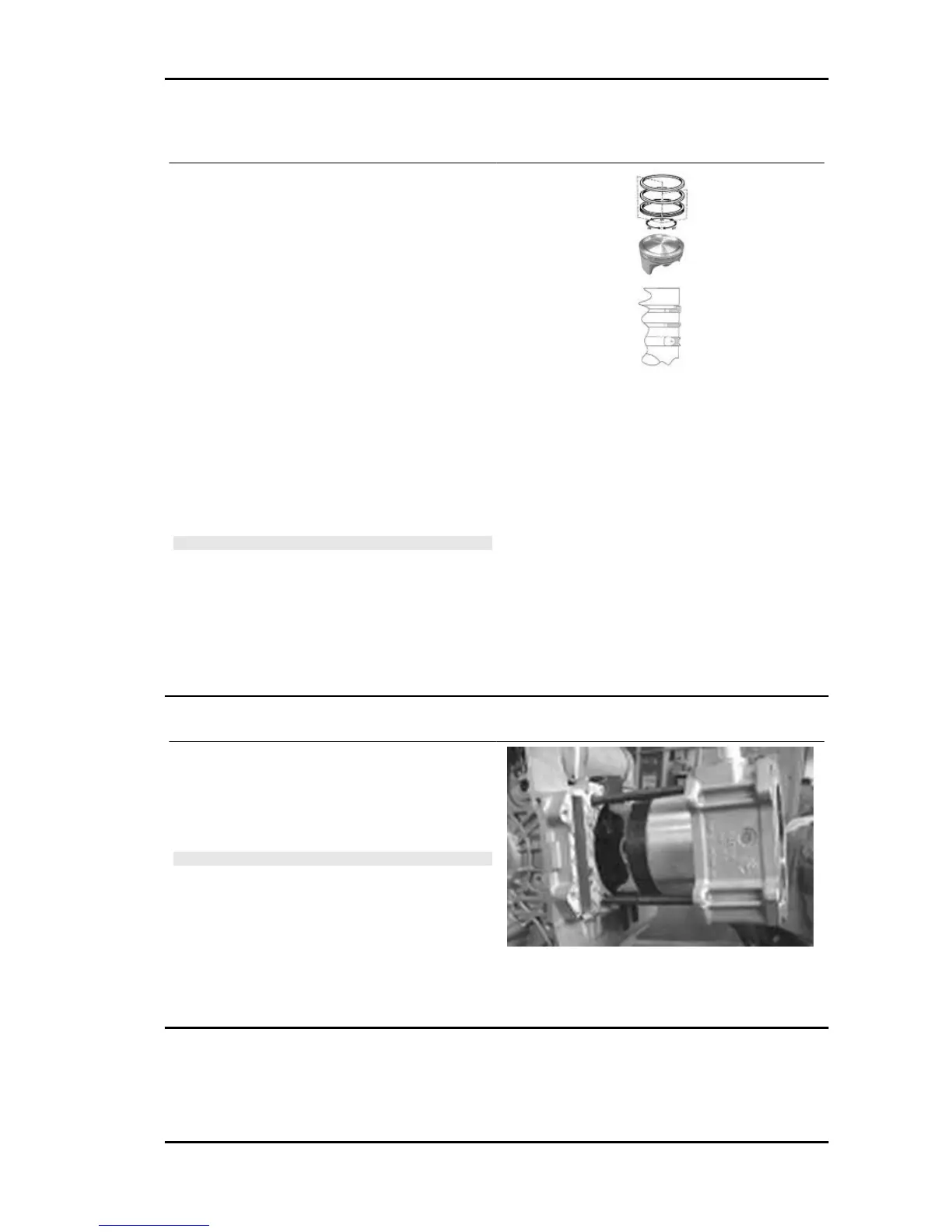

Refitting the cylinder

- Insert the cylinder base gasket with the thickness

determined above.

- Using the fork and the ring clamp, fit the cylinder

as shown in the figure.

N.B.

BEFORE FITTING THE CYLINDER, CAREFULLY BLOW

THE LUBRICATION DUCT AND LUBRICATE THE CYLIN-

DER LINER. CHECK THE PRESENCE OF THE TWO REF-

ERENCE DOWELS.

Specific tooling

020468Y Piston assembly band

020512Y Piston fitting fork

Inspecting the cylinder head

- Using a trued bar and a feeler gauge check that the cylinder head surface is not worn or distorted.

Characteristic

Beverly 500 i.e. Engine

ENG - 117

Loading...

Loading...