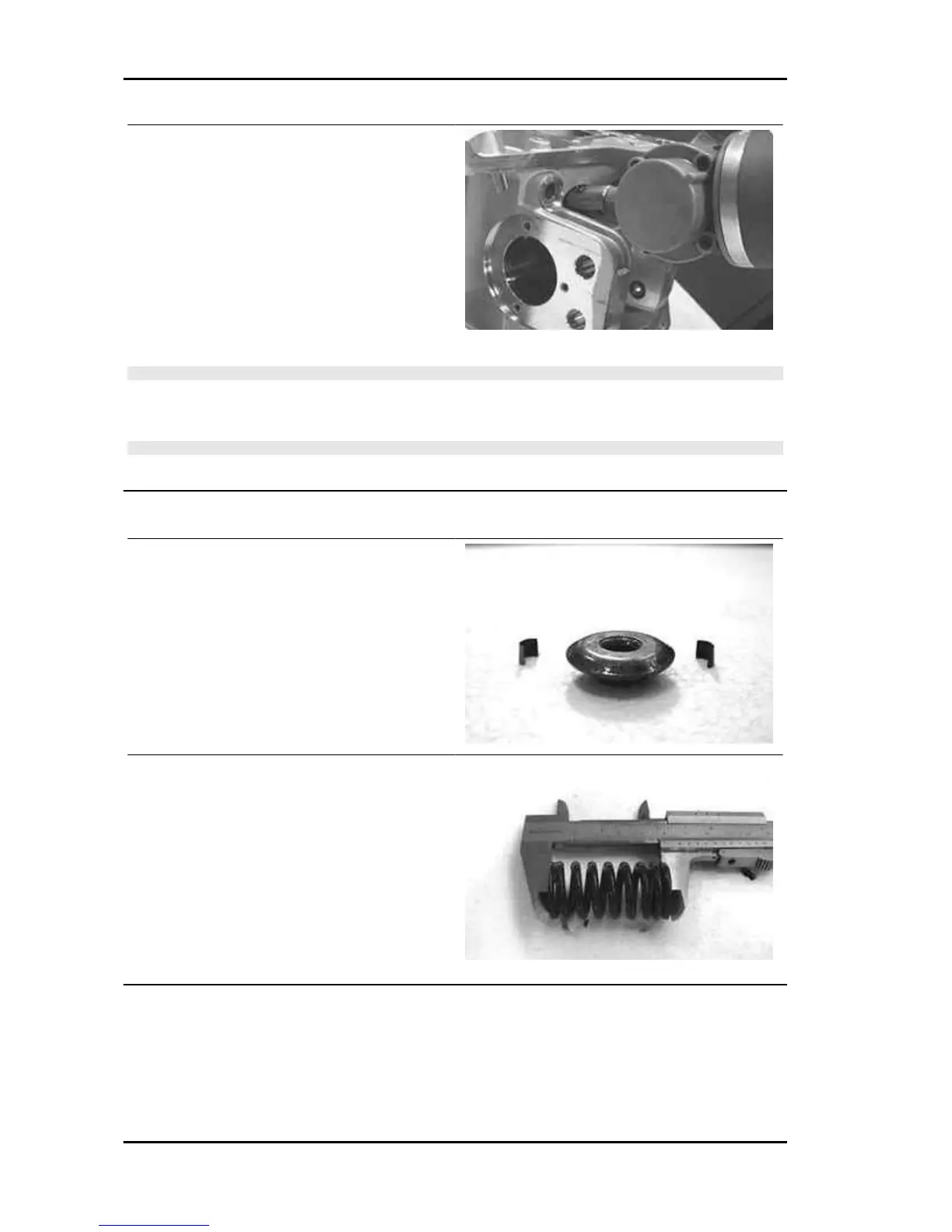

- If no faults are found during the above checks,

you can use the same valves. To obtain better

sealing performance, grind the valve seats. Grind

the valves gently with a fine-grained lapping com-

pound. During the grinding, keep the cylinder head

with the valve axes in a horizontal position. This

will prevent the lapping compound residues from

penetrating between the valve stem and the guide

(see figure).

CAUTION

TO AVOID SCORING THE FAYING SURFACE, DO NOT KEEP ROTATING THE VALVE WHEN NO

LAPPING COMPOUND IS LEFT. CAREFULLY WASH THE CYLINDER HEAD AND THE VALVES

WITH A SUITABLE PRODUCT FOR THE TYPE OF LAPPING COMPOUND BEING USED.

CAUTION

DO NOT REVERSE THE FITTING POSITIONS OF THE VALVES (RIGHT - LEFT).

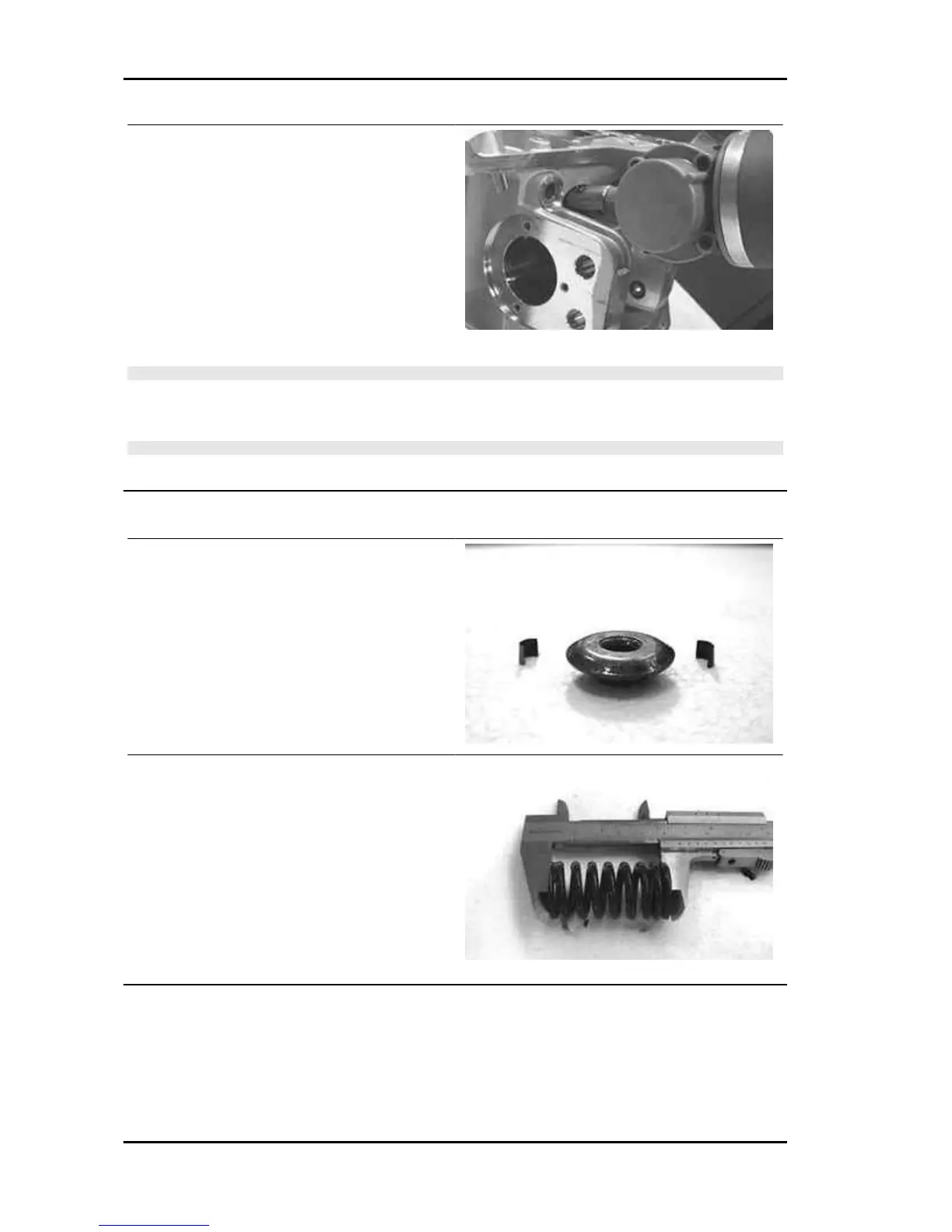

Inspecting the springs and half-cones

- Check that the upper spring caps and the cotter

halves show no signs of abnormal wear.

- Measure the unloaded spring length.

Characteristic

Standard length:

44.4 mm

Admissible limit after use:

42.4 mm

Engine Beverly 500 i.e.

ENG - 122

Loading...

Loading...