N.B.

IF YOU HAVE TO REPLACE THE OIL PUMP AND COUNTERSHAFT CONTROL GEAR IT IS NEC-

ESSARY TO REPLACE THE COUNTERSHAFT GEAR AS WELL.

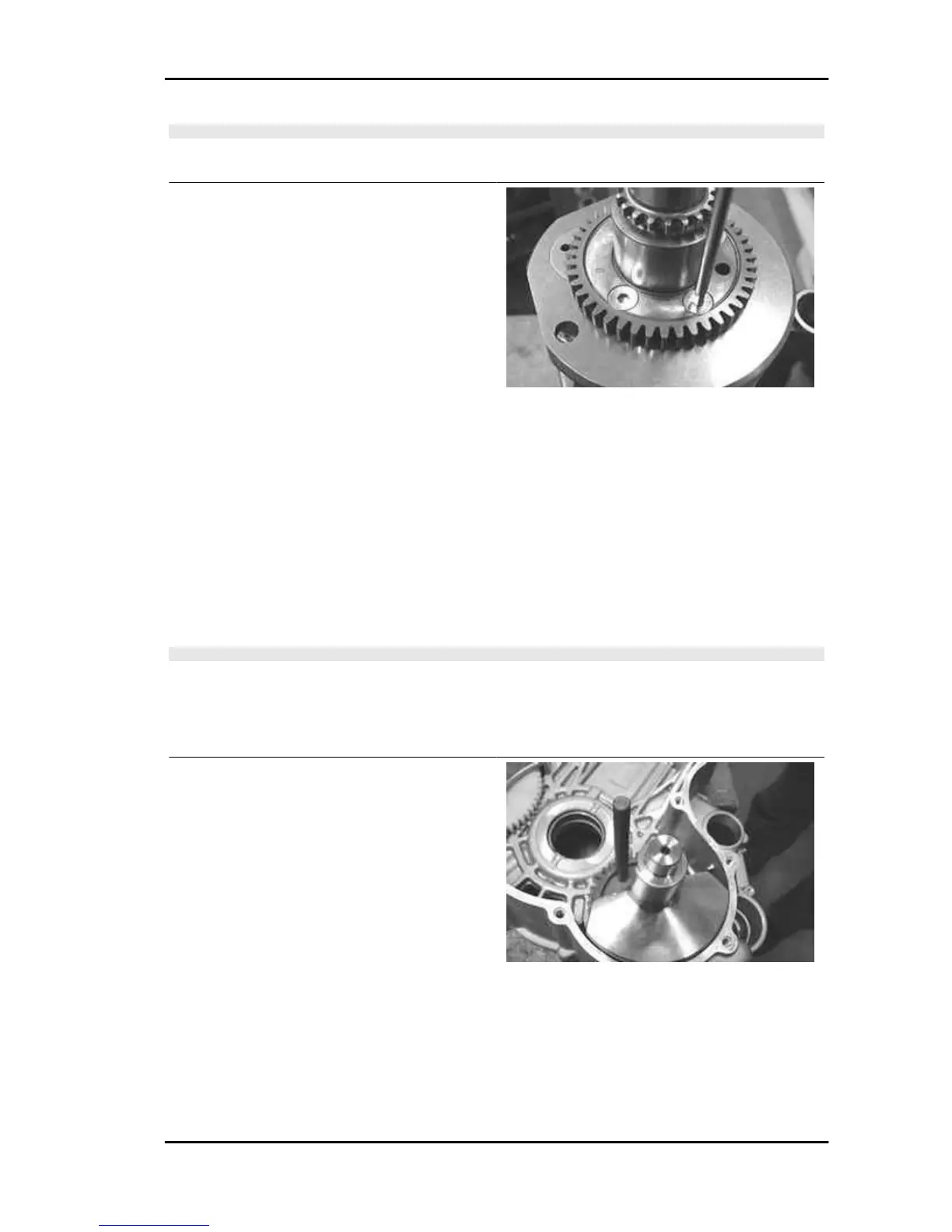

- Before installing the gear on the crankshaft, care-

fully clean the two matching surfaces removing

any residues of LOCTITE from the holes using a

brush.

Blow with compressed air and degrease the mounting holes on both surfaces to make the new LOCTITE

grip.

Apply the recommended product to the holes again.

Recommended products

Loctite 243 Medium-strength threadlock

Loctite 243 medium-strength threadlock

- Repeat the same procedure for the 4 fastening screws.

- Insert the control gear on the crankshaft with the hole countersink visible.

- Tighten the 4 fastening screws to the prescribed torque.

N.B.

TO AVOID DAMAGING THE SCREW CONTROL HEXAGON, IT IS PREFERABLE TO USE AN IN-

SIDE HEXAGON SOCKET WRENCH.

Locking torques (N*m)

Gear mounting on crankshaft screws 10 -12

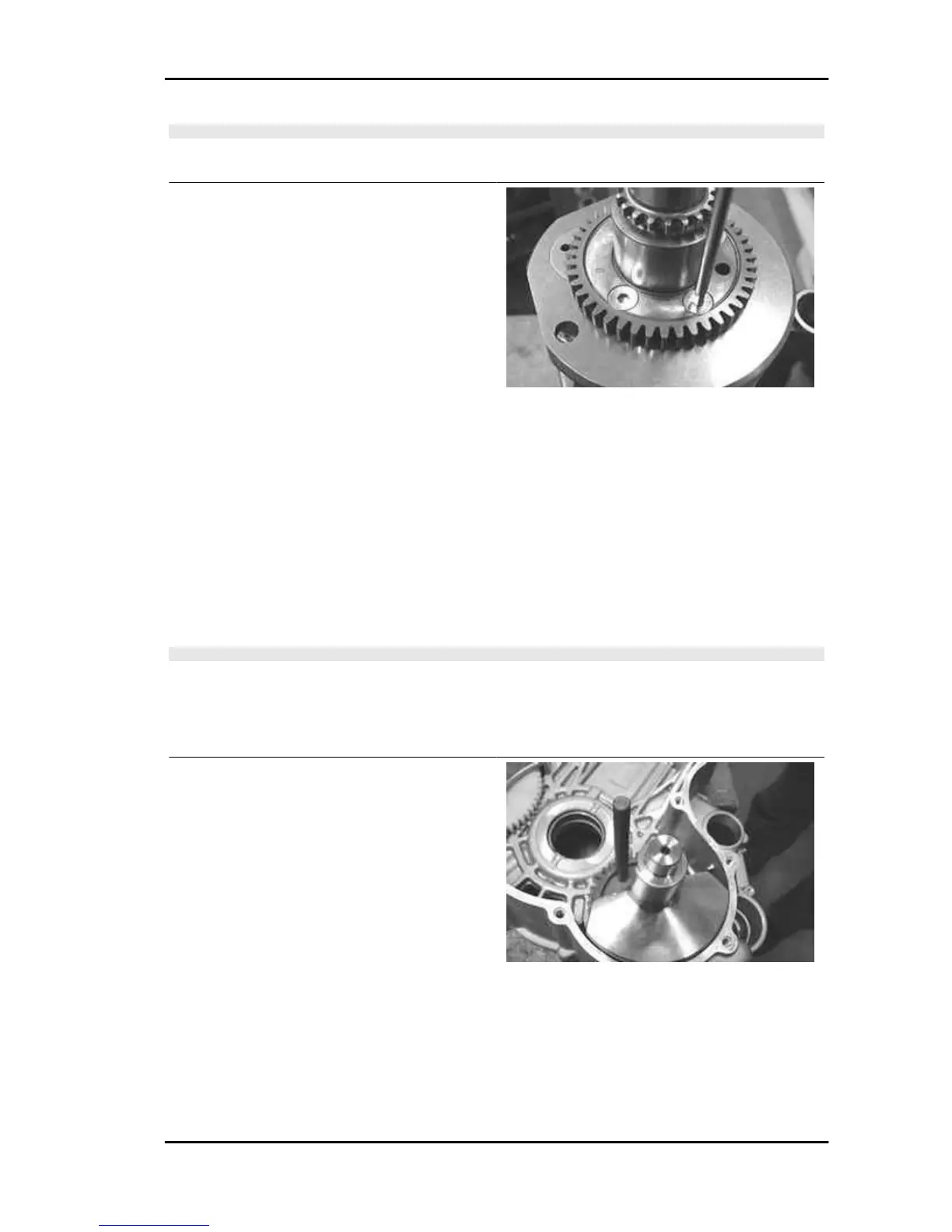

- Lubricate the main bearing on the flywheel side

half-crankcase.

- Lubricate the shim adjustment washer.

- Insert the shim adjustment washer on the crank-

shaft in its original position.

- Insert the special timing tool in the hole on the

countershaft.

Specific tooling

020471Y Pin for countershaft timing

X8 400 Euro 3 Engine

ENG - 175

Loading...

Loading...