GENERAL INFORMATION

1.22

Tread

Depth 1/8I (3 mm)

FRAME, NUTS, BOLTS,

F

ASTENERS

Periodically inspect the torque of all fasteners in

accordance with the maintenance schedule. Check

that all cotter pins are in place. Refer to specific

fastener torques listed in each chapter.

CAMBER AND CASTER

The camber and caster are non-adjustable.

STEERING

The steering components should be checked

periodically for loose fasteners, worn tie rod ends, and

damage. Also check to make sure all cotter pins are

in place. If cotter pins are removed, they must not be

re-used. Always use new cotter pins.

Replace any worn or damaged steering components.

Steering should move freely through entire range of

travel without binding. Check routing of all cables,

hoses, and wiring to be sure the steering mechanism

is not restricted or limited. NOTE: Whenever steering

components are replaced, check front end alignment.

Use only genuine Polaris parts.

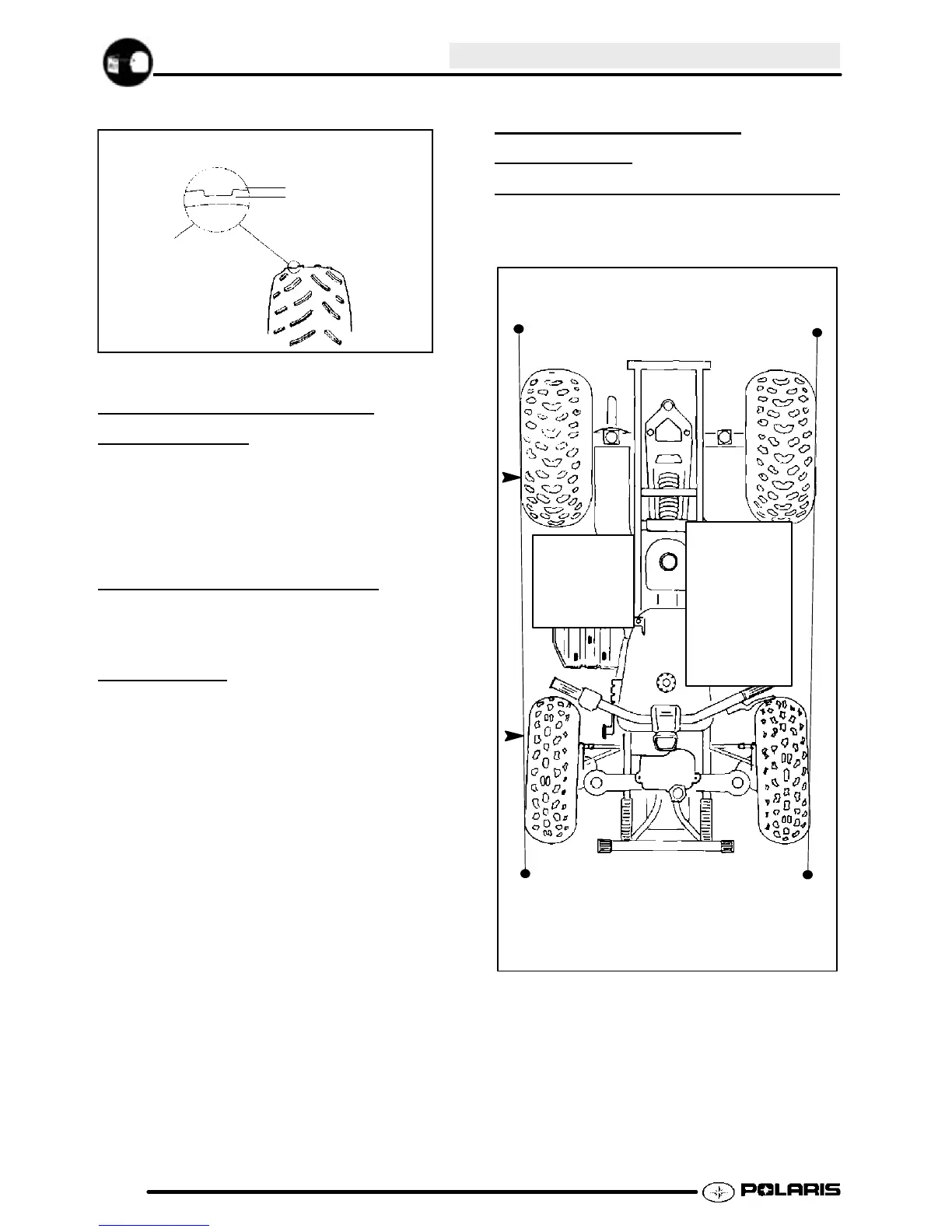

WHEEL ALIGNMENT

METHOD 1:

STRAIGHTEDGE OR STRING

Be sure to keep handlebars centered. See notes

below.

NOTE: String should just touch side sur-

face of rear tire on each side of machine.

NOTE: The steering post arm “frog” can be

used as an indicator of whether the handle-

bars are straight. The frog should always

point straight back from the steering post.

Rear rim

measure-

ment should

be 1/16² to

1/8² (.2to.3

cm) more

than front rim

measure-

ment.

Measure

from string

to rim at

front and

rear of rim.

Enfocus Software - Customer Support

Loading...

Loading...