ENGINE

2.13

Cylinders may be wet or dry honed depending upon

the hone manufacturer’s recommendations. Wet

honing removes more material faster and leaves a

more distinct pattern in the bore.

HONING TO OVERSIZE

If cylinder wear or damage is excessive, it will be

necessary to oversize the cylinder using a new

oversize piston and rings. This may be accomplished

by either boring the cylinder and then finish honing to

the final bore size, or rough honing followed by finish

honing.

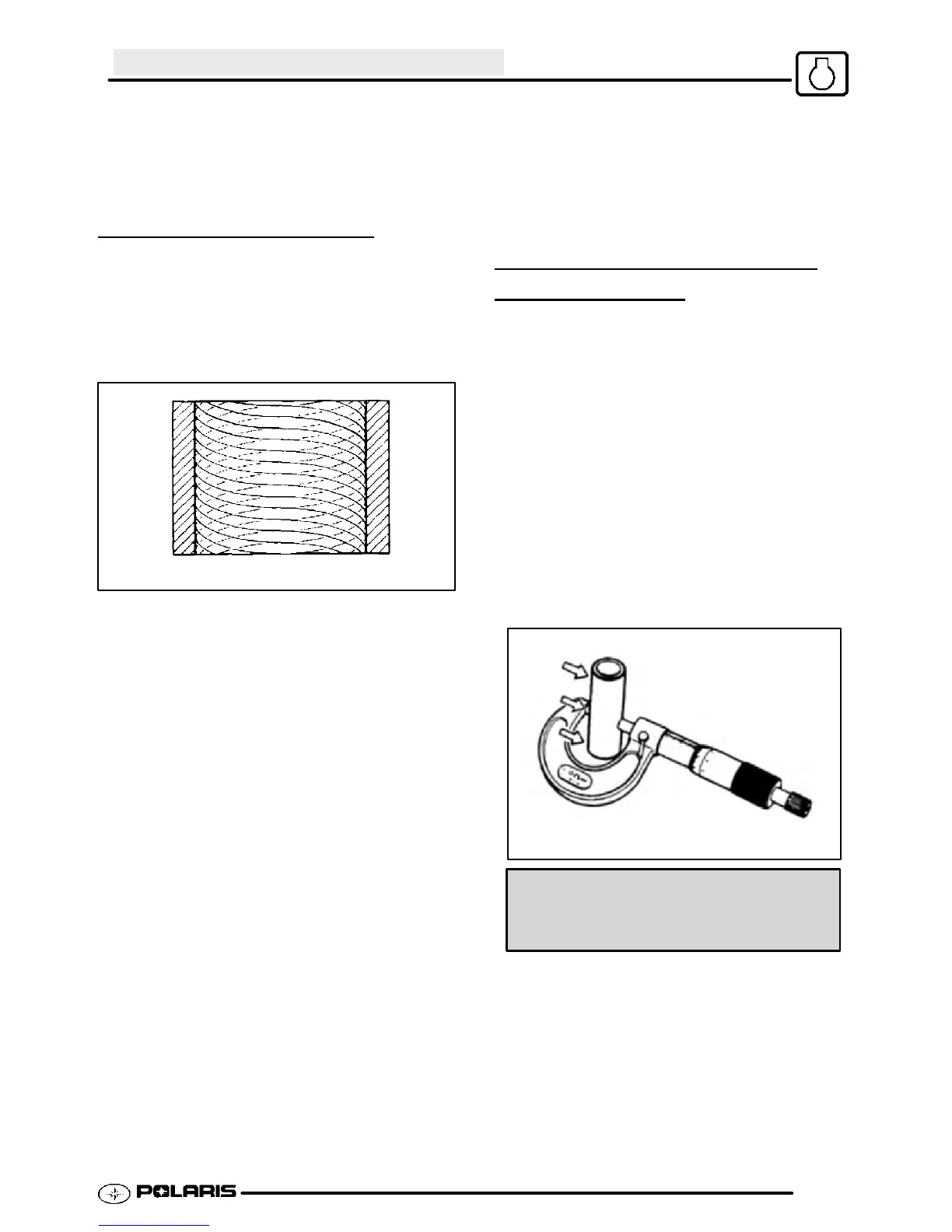

EXAMPLE OF CROSS HATCH PATTERN

For oversize honing, always wet hone using the

specified oil and coarse roughing stones. Measure

the piston (see piston measurement) and rough hone

to the size of the piston. Always leave .002 - .003² (.05

- .07 mm) for finish honing. Refer to piston-to-cylinder

clearance specifications on Page 2.17 before honing.

Complete the sizing with fine grit stones to provide the

proper cross-hatch finish and required piston

clearance.

A finished cylinder should have a cross-hatch pattern

to ensure piston ring seating and to aid in the retention

of the fuel/oil mixture during operation. Hone cylinder

according to hone manufacturer’s instructions, or

these guidelines:

G Use a motor speed of approximately

300-500 RPM, run the hone in and out of

the cylinder rapidly until cutting tension

decreases. Remember to keep the hone

drive shaft centered (or cylinder centered

on arbor) and to bring the stone

approximately 1/2² (1.3 cm) beyond the

bore at the end of each stroke.

G Release the hone at regular intervals and

inspect the bore to determine if it has been

cleared, and to check piston fit. NOTE:

Do not allow cylinder to heat up during

honing. The thinner areas of the liner

around the ports will expand causing

uneven bore.

G After honing has been completed inspect

all port opening areas for rough or sharp

edges. Apply a slight chamfer to all ports

to remove sharp edges or burrs, paying

particular attention to the corners of the

intake and exhaust ports.

CLEANING THE CYLINDER

AFTER

HONING

It is very important that the cylinder be thoroughly

cleaned after honing to remove all grit material. Wash

the cylinder in solvent, then in hot, soapy water. Pay

close attention to areas where the cylinder sleeve

meets the aluminum casting (transfer port area). Use

electrical contact cleaner if necessary to clean these

areas. Rinse thoroughly, dry with compressed air,

and oil the bore immediately with Polaris 2 Cycle

Lubricant to prevent the formation of rust.

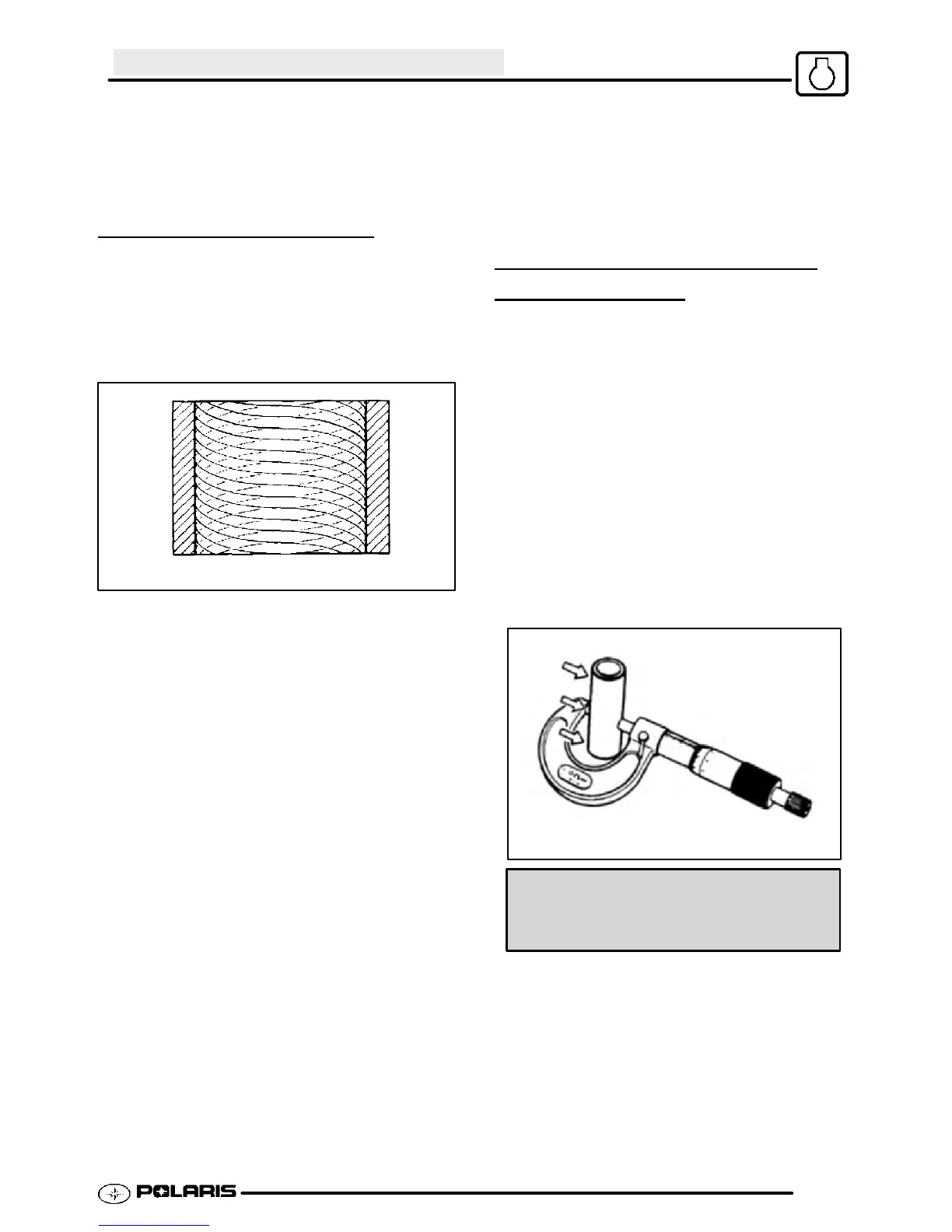

Piston Pin Inspection

1. Inspect the surface of the piston pin for damage.

Measure the diameter of the piston pin in three

areas with a micrometer. The service limit for the

piston pin is .393² (9.980 mm).

Piston Pin

Service Limit:

.393I (9.980 mm)

Connecting Rod Inspection

1. Inspect the inner surface of the small end of the

connecting rod for wear or damage. Oil and install

needle bearing and pin in connecting rod. Rotate

pin slowly and check for rough spots or any

resistance to movement. Replace both pin and

bearing if there is any resistance to rotation.

Measure the inner diameter of the small end of the

connecting rod. The service limit is .553² (14.04

mm).

Enfocus Software - Customer Support

Loading...

Loading...